Gear power transfer device having function of noise reduction

A power transmission and gear technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve problems such as lack of shock absorption and noise reduction, inability to guarantee the concentricity of planetary gear sets, difficulties in design and manufacture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with the drawings and embodiments

[0018] To further explain the present invention:

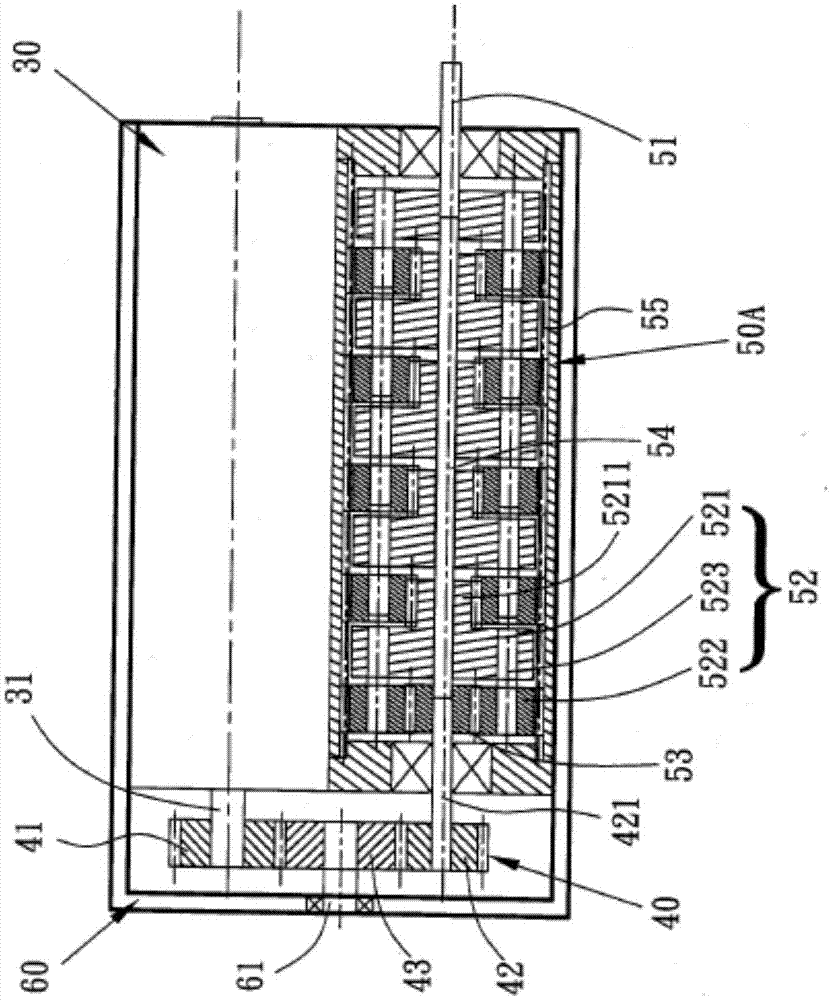

[0019] Such as figure 1 As shown, a gear power transmission device with noise reduction function includes a housing 60 with a number of heat dissipation ports; a soundproof chamber, a motor 30, a gear set 40 and planetary gears are provided in the housing 60 Group assembly 50A;

[0020] The motor 30 is arranged in a soundproof room, and a motor output shaft 31 is arranged on the motor 30, and the motor output shaft 31 extends out of the soundproof room (not shown in the figure); in order to improve the sound insulation effect, the soundproof room is composed of six asbestos soundproof boards. A first gear 41 is sleeved on the motor output shaft 31.

[0021] The gear set 40 includes a second gear 43, a transmission shaft 61, a third gear 42, and an output shaft 421;

[0022] The first gear 41 meshes with the second gear 43, the second gear 43 is sleeved on the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com