Measuring device and method for angle measurement accuracy of large-diameter photoelectric theodolite

A photoelectric theodolite and angle measurement accuracy technology, applied in the optical field, can solve the problems that the angle measurement accuracy of the large-diameter photoelectric theodolite cannot be objectively and truly reflected, and the high-angle target light tube cannot completely cover the theodolite caliber, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

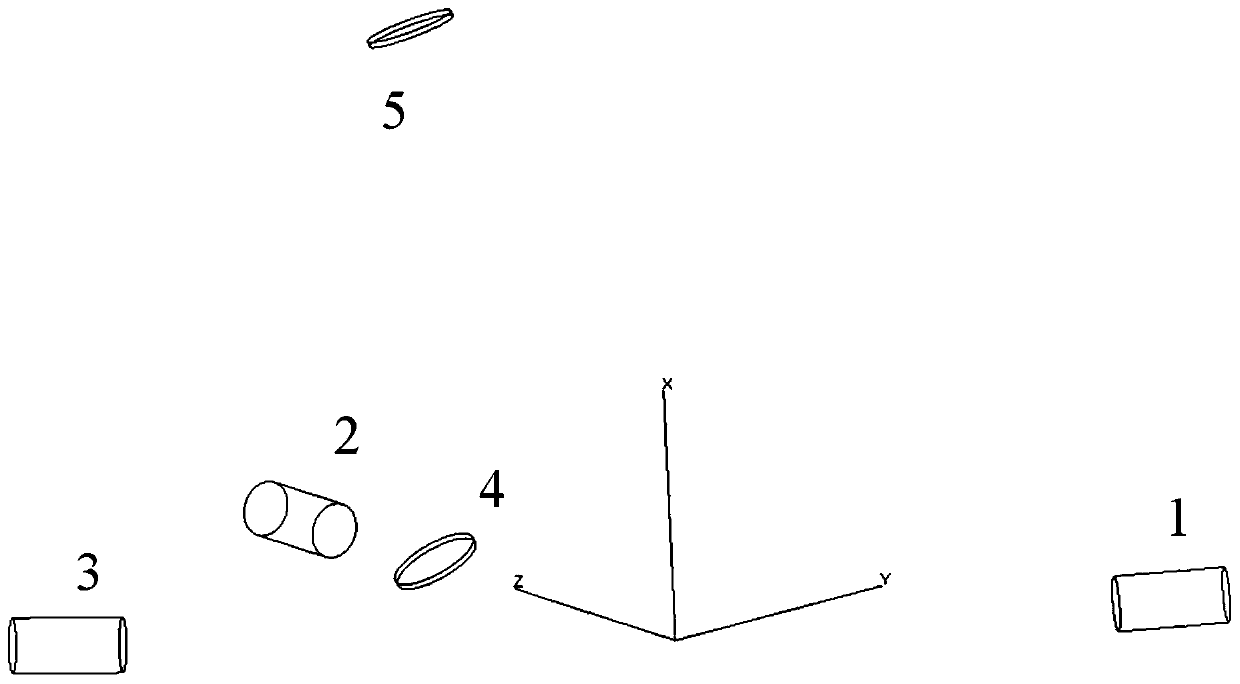

[0033] like figure 1 As shown, the large-caliber photoelectric theodolite angle measurement accuracy test device provided by the present invention includes a first target light pipe 1, a second target light pipe 2, a third target light pipe 3, a first reflector 4, a detection frame and installed in The second reflecting mirror 5 ( figure 1 not shown); the second reflector 5 is located above the first reflector 4 .

[0034] The first target light pipe 1 , the second target light pipe 2 , the third target light pipe 3 , the first reflector 4 and the second reflector 5 are arranged according to specific space angle frames. The specific setting method is as follows:

[0035] First of all, the pitch angle of the output beams of the first target light pipe 1, the second target light pipe 2 and the third target light pipe 3 must be adjusted to 90°0'0", and ensure that the first target light pipe and the third target light The optical axes of the tubes intersect at a point.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com