High-temperature emulsification dynamic testing instrument and method

A high-temperature emulsification and tester technology, applied in instruments, measuring devices, mechanical devices, etc., can solve the problems of difficulty in measuring the initial emulsification amount, difficult to read, and oil adheres to the wall surface, and achieves repeatable operation and experimental cycle. Short, error-eliminating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

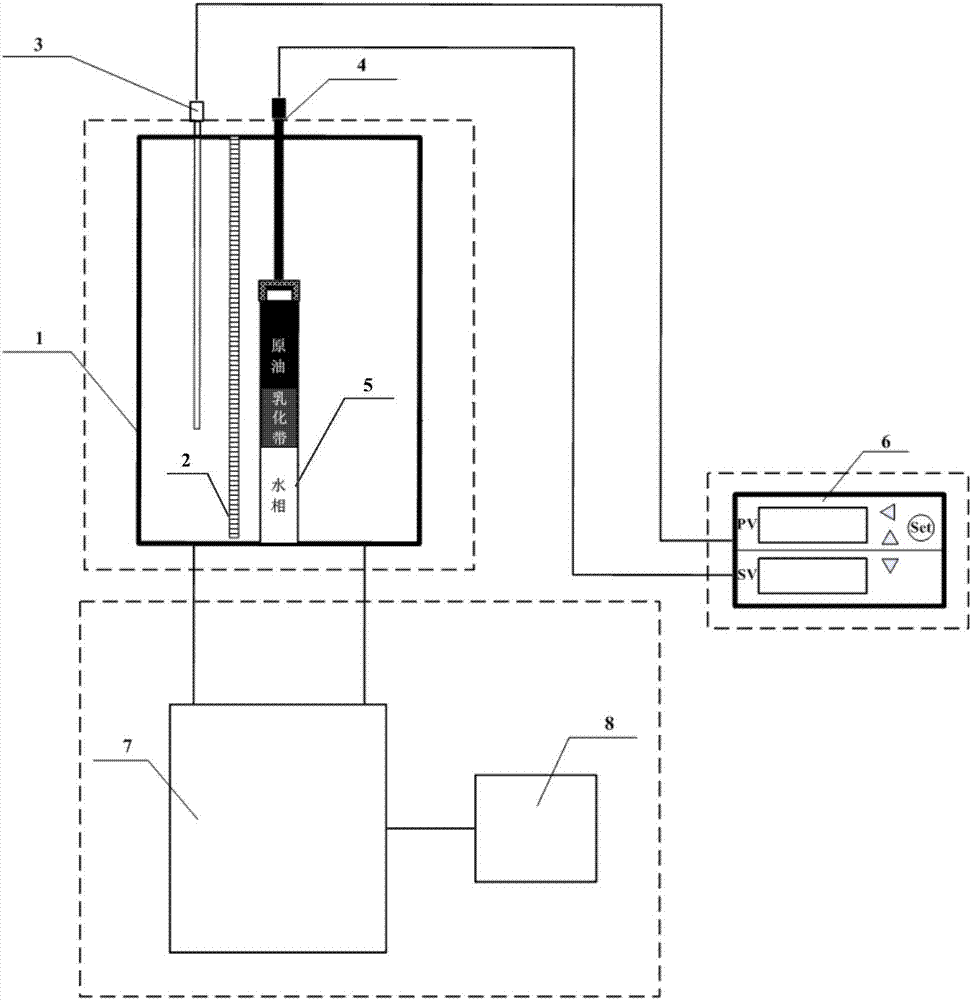

[0086] This embodiment provides a high-temperature emulsification dynamic tester, and its structural schematic diagram is as follows figure 1 shown.

[0087] The high-temperature emulsification dynamic tester includes a visual emulsification unit, and a vibration unit and a temperature control unit that are respectively connected to the visual emulsification unit; wherein,

[0088] The visible emulsification unit includes a temperature-resistant and pressure-resistant glass cylinder 1, a steel ruler 2 and a glass test tube 5; ℃ high temperature and 1.5MPa pressure; the top of the steel ruler 2 is connected to the top of the temperature-resistant and pressure-resistant glass cylinder 1, and the bottom of the steel ruler 2 is suspended and not connected to the bottom of the temperature-resistant and pressure-resistant glass cylinder 1. The steel ruler 2 is along the direction from the top to the bottom, and the scale value thereon decreases gradually; the top of the glass test...

Embodiment 2

[0092] The present embodiment provides a high-temperature emulsification dynamic test method, which includes the following steps:

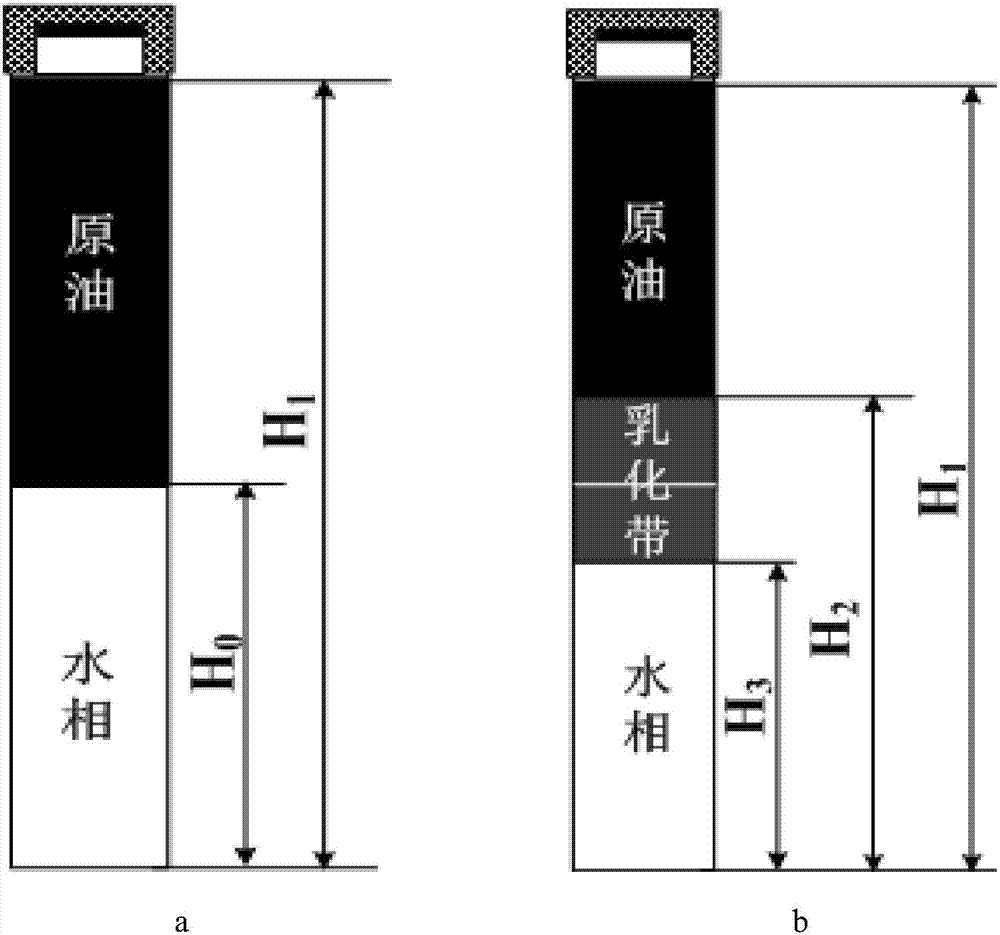

[0093] Add the pre-prepared emulsifier solution (water phase) into the glass test tube 5 first, then add the oil sample (oil phase), the volume ratio of the two is 1:1, after adding the oil sample, tighten the cork to seal.

[0094] Put the glass test tube 5 into the temperature-resistant and pressure-resistant glass cylinder 1, keep the glass test tube 5 vertically upward, at this time, the water phase is on the bottom, and the oil phase is on the top; at the same time, the initial scale value on the steel ruler 2 is at the bottom of the water phase On the same horizontal line / plane for easy reading of height.

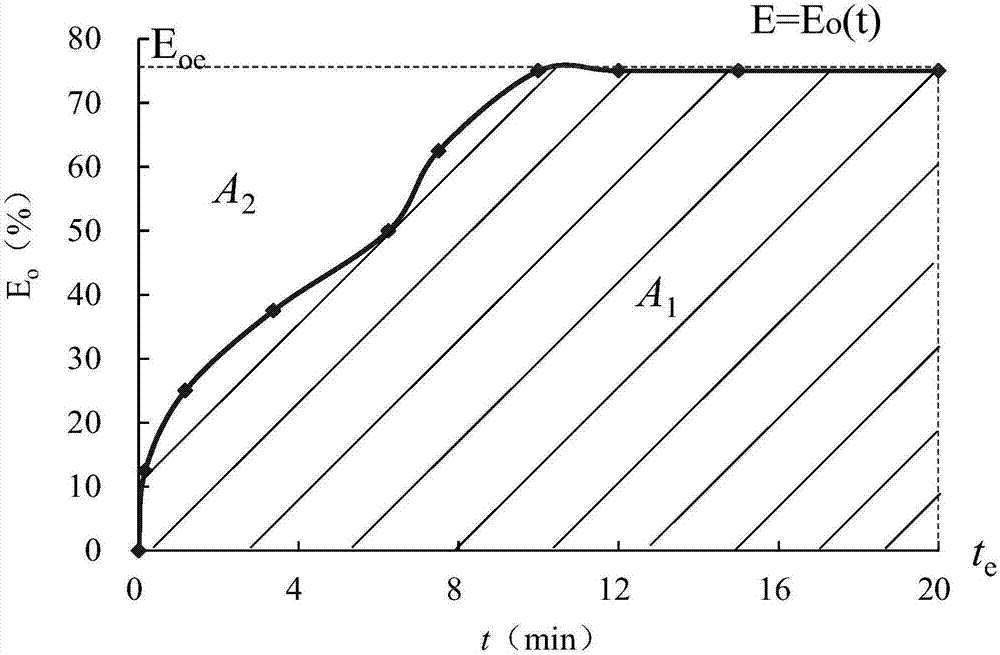

[0095] Inject deionized water as a heating medium into the temperature-resistant and pressure-resistant glass cylinder 1, and immerse the glass test tube 5. Turn on the temperature controller 6 and set the temperature as the target oil r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com