Ultrasonic sensor

An ultrasonic and sensor technology, applied in the field of ultrasonic sensors, can solve the problems such as the relative position cannot be changed, the accuracy of ultrasonic sensors is limited, etc., to achieve the effect of improving the sensing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following describes in detail through specific embodiments with reference to the accompanying drawings.

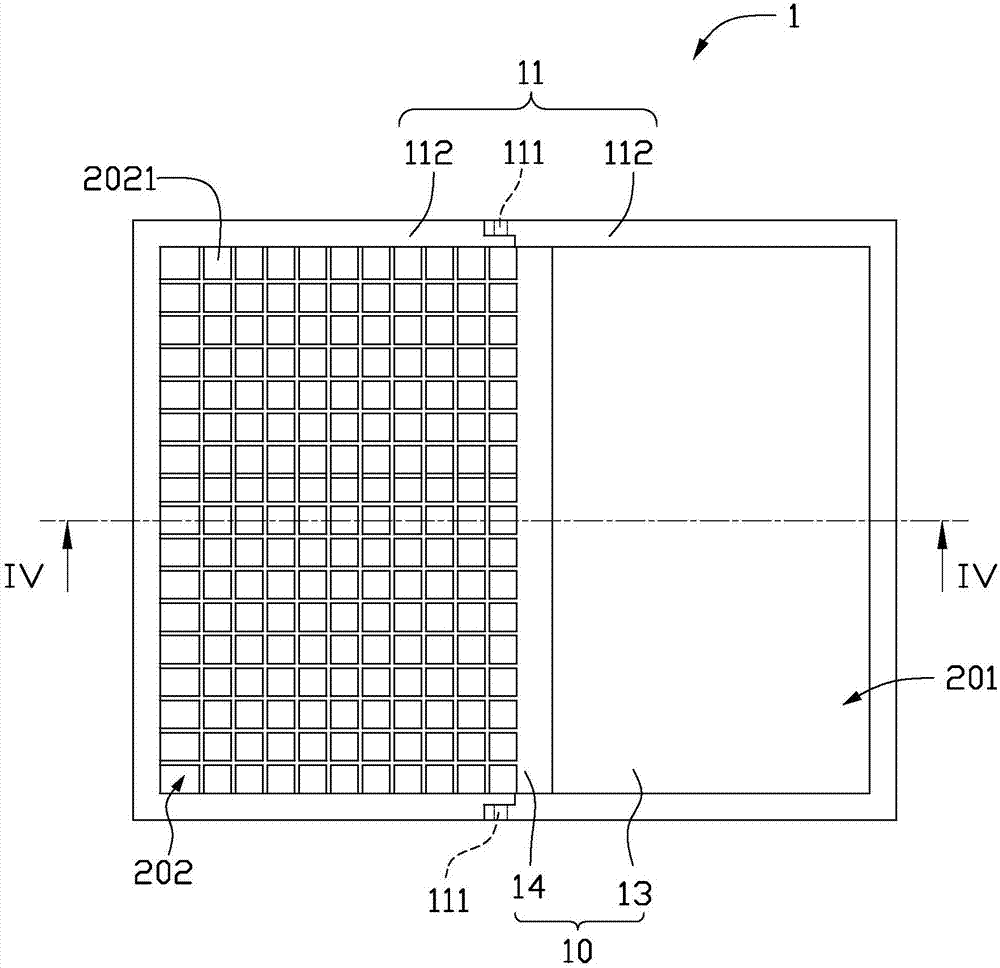

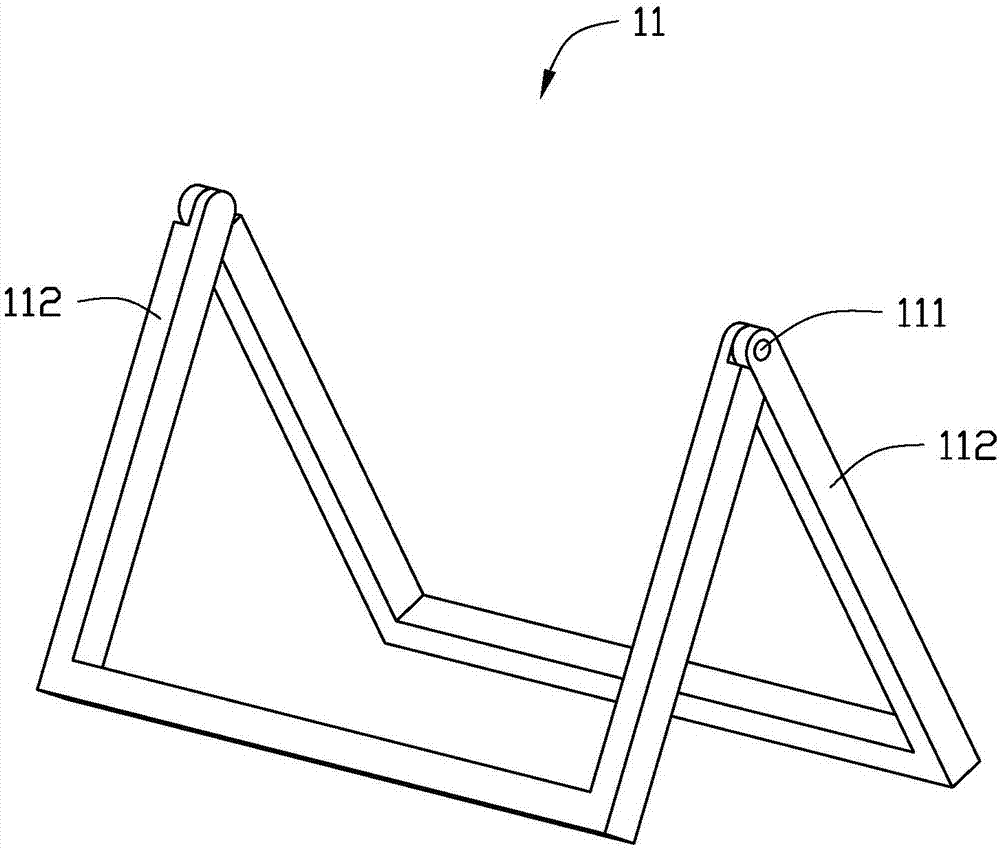

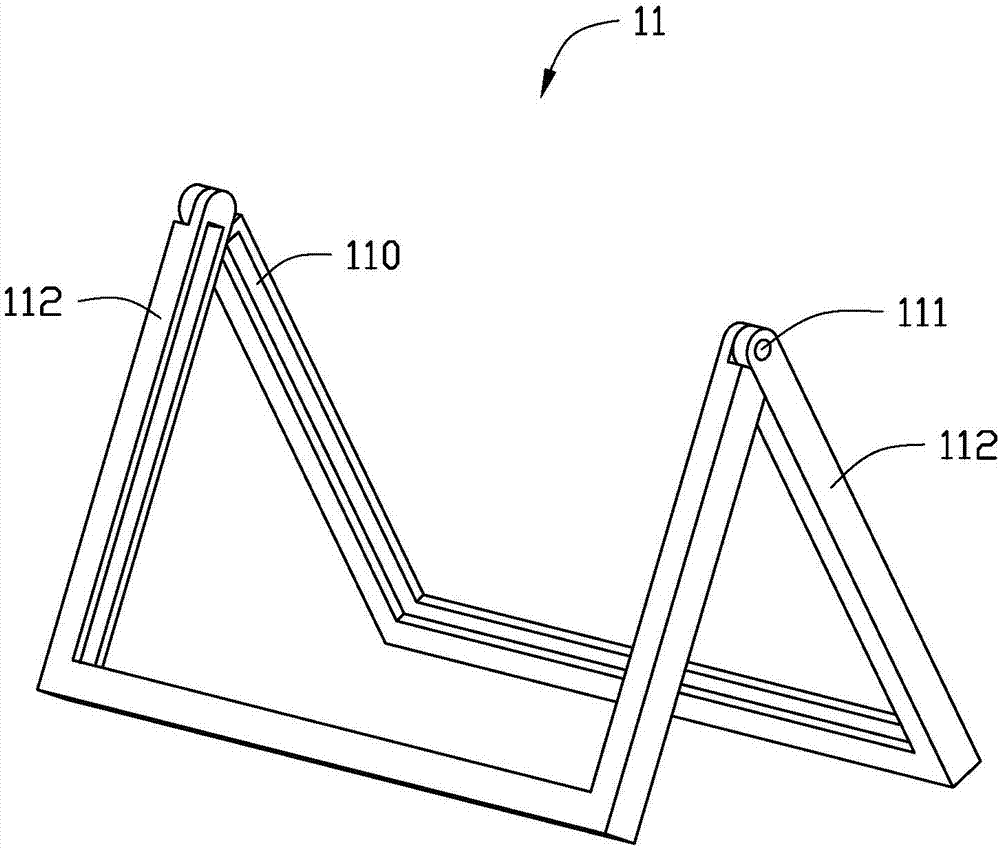

[0017] Please also refer to figure 1 and figure 2 , figure 1 It is a top plan view of the ultrasonic sensor 1 in the expanded state of the present invention. The ultrasonic sensor 1 includes a foldable bracket 11 and a sensing unit 10 fixed on the bracket 11 . see figure 2 , figure 2 for figure 1 Schematic diagram of the structure of the scaffold. The support 11 includes two rotatably connected support parts 112 , that is, the two support parts 112 can be folded and unfolded relative to each other, so that the angle and distance between the two support parts 112 can be adjusted. In this embodiment, the bracket further includes a hinge 111 connecting the two bracket parts 112 , and the two bracket parts 112 can relatively rotate through the hinge 111 . Each of the bracket parts 112 may be in the shape of a U-shaped frame or a flat plate. In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com