Three-dimensional stacked packaging module single-board testing tool and testing method

A technology for testing tooling and packaging modules, which is applied in the direction of electronic circuit testing, etc. It can solve the problems of large sliding resistance between positioning pins and positioning holes, small volume of three-dimensional packaging modules, and large mounting surface area of connectors, etc., to achieve convenient operation and small clearance , the effect of simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

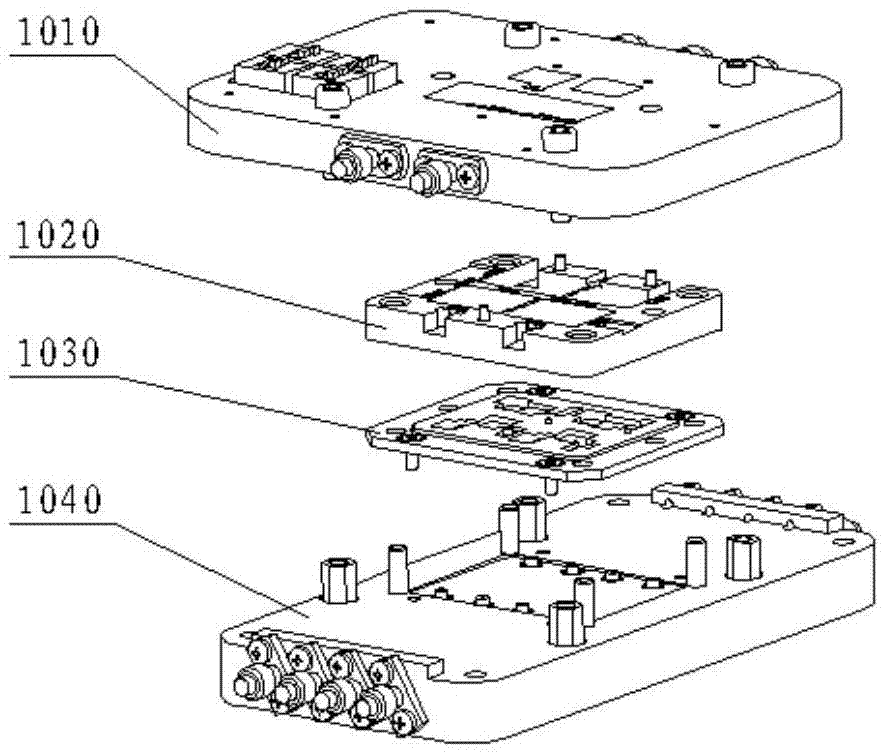

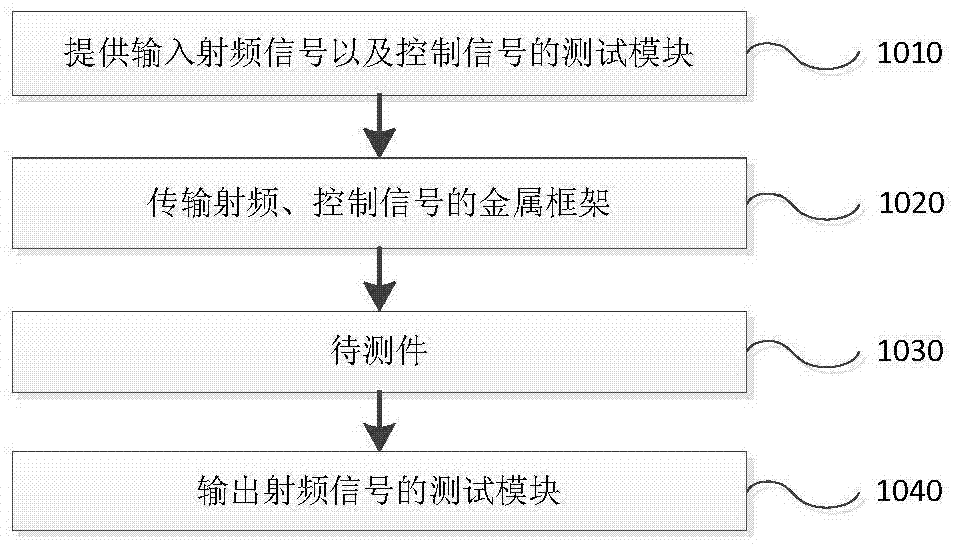

[0033] Such as figure 1 and Figure 9 As shown, the implementation steps of the test method are:

[0034] 1) Tooling testing and calibration: testing and calibration of the control signal, radio frequency signal circuit board and its installation module 1010 . Test and calibrate the RF signal output module 1040 .

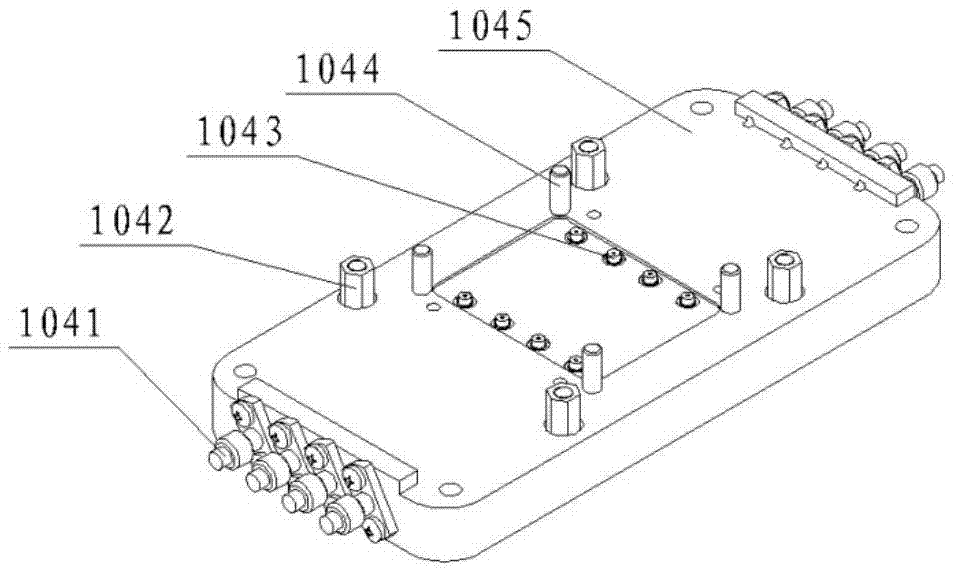

[0035] 2) Module assembly: the circuit board under test and its fixing frame 1030 and the radio frequency signal output module 1040 are positioned through the edges, and connected together with screws to form a base module. The control signal, radio frequency signal circuit board and its installation module 1010, the vertical interconnection connector and its installation frame 1020 are positioned by positioning pins, and connected together by screws to form a pressing board module.

[0036] 3) Test: 4 guide posts and guide sleeves are used for positioning and guiding between the base plate module and the pressure plate module, and the base plate module and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com