Ground mobile charging robot applied to electric automobile based on magnetic suspension internal rotor flywheel energy storage

A technology of mobile charging and flywheel energy storage, which can be used in charging stations and motors for charging electric vehicles and mobile devices, and can solve problems such as charging difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

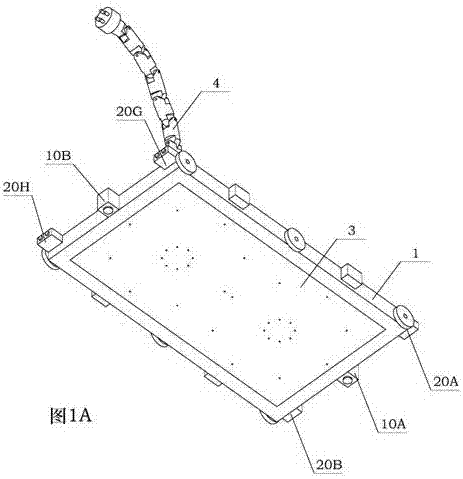

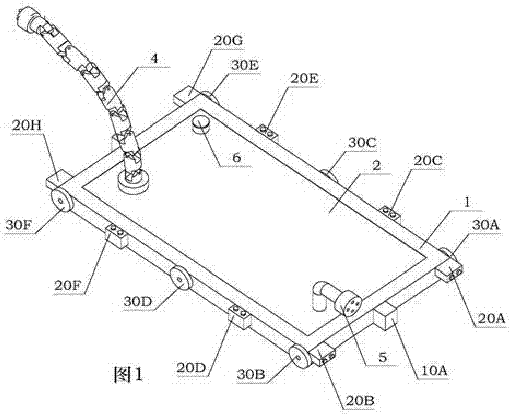

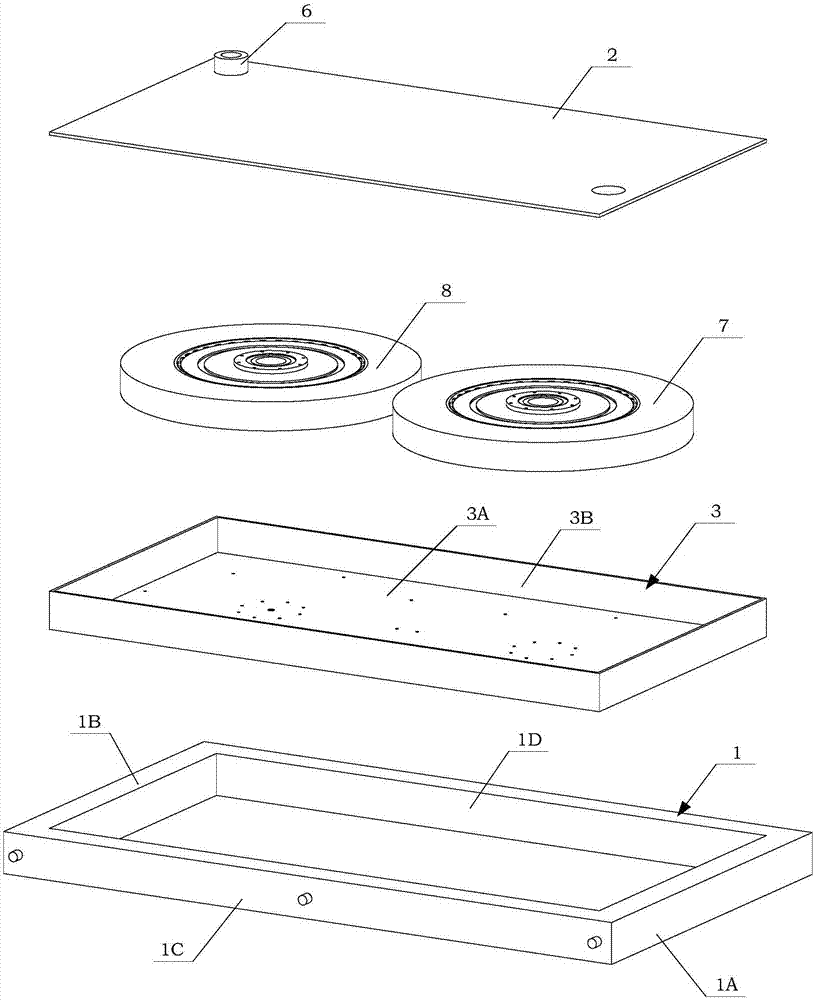

[0033] see figure 1 , Figure 1A , Figure 1B , Figure 1C As shown, the present invention designs a ground mobile charging robot based on magnetic levitation inner rotor flywheel energy storage applied to electric vehicles, which includes a carrier 1, an upper cover 2, a base 3, a multi-joint charging arm 4, a spare charging Interface 5, air extraction equipment 6, group A maglev energy storage flywheel 7, group B maglev energy storage flywheel 8. Vision sensors ( 20A-20H), ultrasonic sensors ( 10A, 10B) and rollers ( 30A- 30F ) are installed outside the side beams of the carrier 1 . The displacement sensors (75, 76) are arranged inside the magnetic suspension energy storage flywheel (7, 8). The multi-joint charging arm 4 is used to connect with the charging connector of the electric vehicle to realize the transmission of electric energy (discharging pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com