Method for inhibiting PCB drilling burr

A kind of PCB board, burr technology, applied in the direction of printed circuit manufacturing, electrical components, printed circuits, etc., can solve the problem of poor drilling burr suppression effect, etc., to improve the appearance quality, improve the ability to suppress burrs, reduce the generation of air bubbles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

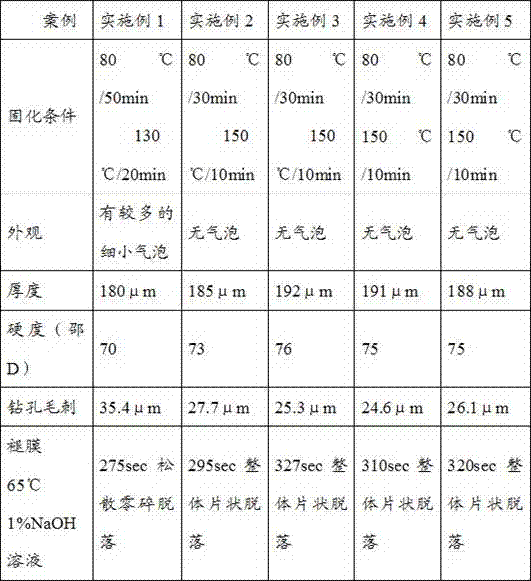

Embodiment 1

[0032] Choose a water-based polyurethane resin as the main resin, match with auxiliary materials and additives, control a certain viscosity to obtain a composite resin, and coat a thicker resin layer on the metal surface of the PCB board (the side in contact with the backing board) , The wet film thickness is about 400μm. After baking and curing, the total film thickness (resin layer) on the metal surface of the PCB board is about 180μm. The burr length is tested by drilling.

Embodiment 2

[0034] Select the above-mentioned composite resin, and coat a thick resin layer on the metal surface of the PCB. 2 The wood fiber cloth is placed on the coated resin surface, and the wood fiber cloth is soaked in the resin. After baking and curing, the total film thickness (including the resin layer and wood fiber cloth) on the metal surface of the PCB board is about 185 μm. The burr length is tested by drilling.

Embodiment 3

[0036] Select the above-mentioned composite resin, and coat a thick resin layer on the metal surface of the PCB board. 2 The non-woven glass fiber cloth is placed on the coated resin surface, and the non-woven glass fiber cloth is soaked in the resin. After baking and curing, the total film thickness of the metal surface of the PCB board (including the resin layer and the non-woven glass fiber Cloth) is about 192μm, and the burr length is tested by drilling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com