Reactor high-automation stirring device

A technology of stirring device and reaction kettle, which is applied in feeding device, chemical/physical/physical-chemical stationary reactor, chemical instrument and method, etc. The effect of improving the degree of automation and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

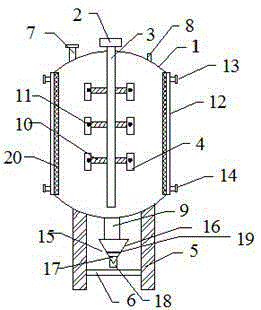

[0014] figure 1 The specific embodiment of the present invention is shown: a high automatic stirring device for a reactor, including a kettle body 1, a stirring motor 2, a stirring shaft 3, a stirring blade 4 and a support seat 5, and the kettle body 1 is arranged on the support seat 5 , a reinforcing rib 6 is provided between the support seats 5, a feed port 7 and a safety valve 8 are provided at the upper end of the kettle body 1, a discharge port 9 is provided at the lower end of the kettle body 1, and the stirring motor 2 is fixed On the top of the kettle body 1, and the stirring motor 2 is connected to the stirring shaft 3 arranged inside the kettle body 1, the stirring shaft 3 is provided with a support frame 10, and the stirring blade 4 is arranged on the support frame 10 through a screw 11 Both ends of the reactor body 1 are provided with a heating jacket 12, and the heating jacket 12 is provided with a water inlet 13 and a water outlet 14.

[0015] In addition, if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com