Pressure vessel

A technology for pressure vessels and cylinders, which is applied in the field of pressure vessels with non-central joints, and can solve problems such as the failure of the function of the joints to control the liquid position in the vessel, the increase in the amount of welding deposited metal filling, and the huge difference in heat input. Achieve the effect of increasing the groove processing effect, improving the welding quality and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, the present invention will be further described in detail through the drawings and embodiments. Through these descriptions, the characteristics and advantages of the present invention will become clearer.

[0060] The dedicated word "exemplary" here means "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" need not be construed as being superior or better than other embodiments. Although various aspects of the embodiments are shown in the drawings, unless otherwise noted, the drawings are not necessarily drawn to scale.

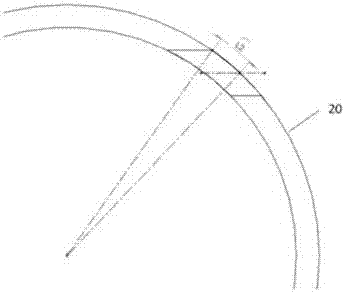

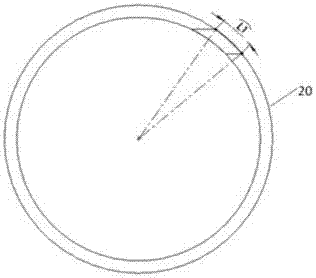

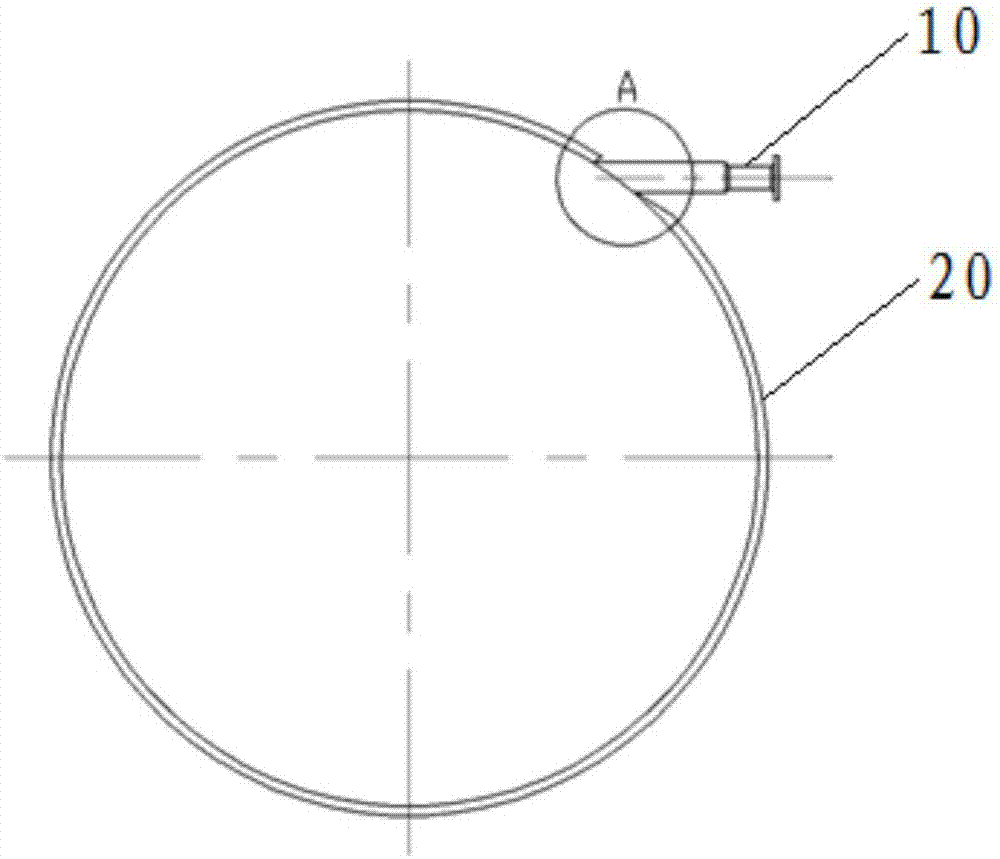

[0061] The present invention provides a pressure vessel with a non-concentric nozzle 10, wherein, in a preferred embodiment, the connection relationship between the non-concentric nozzle 10 and the pressure vessel cylinder 20 is as follows figure 1 As shown, it is preferable that the non-centripetal connection pipe 10 is welded to the barrel 20; and, as figure 2 As shown, in the welding operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com