Opening width adjustable wrench

A technology of opening width and wrench, applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problems of reducing assembly efficiency, damage to the sharp edge of bolts and nuts, increasing opening gap, etc., to reduce the type and quantity, improve assembly efficiency, The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

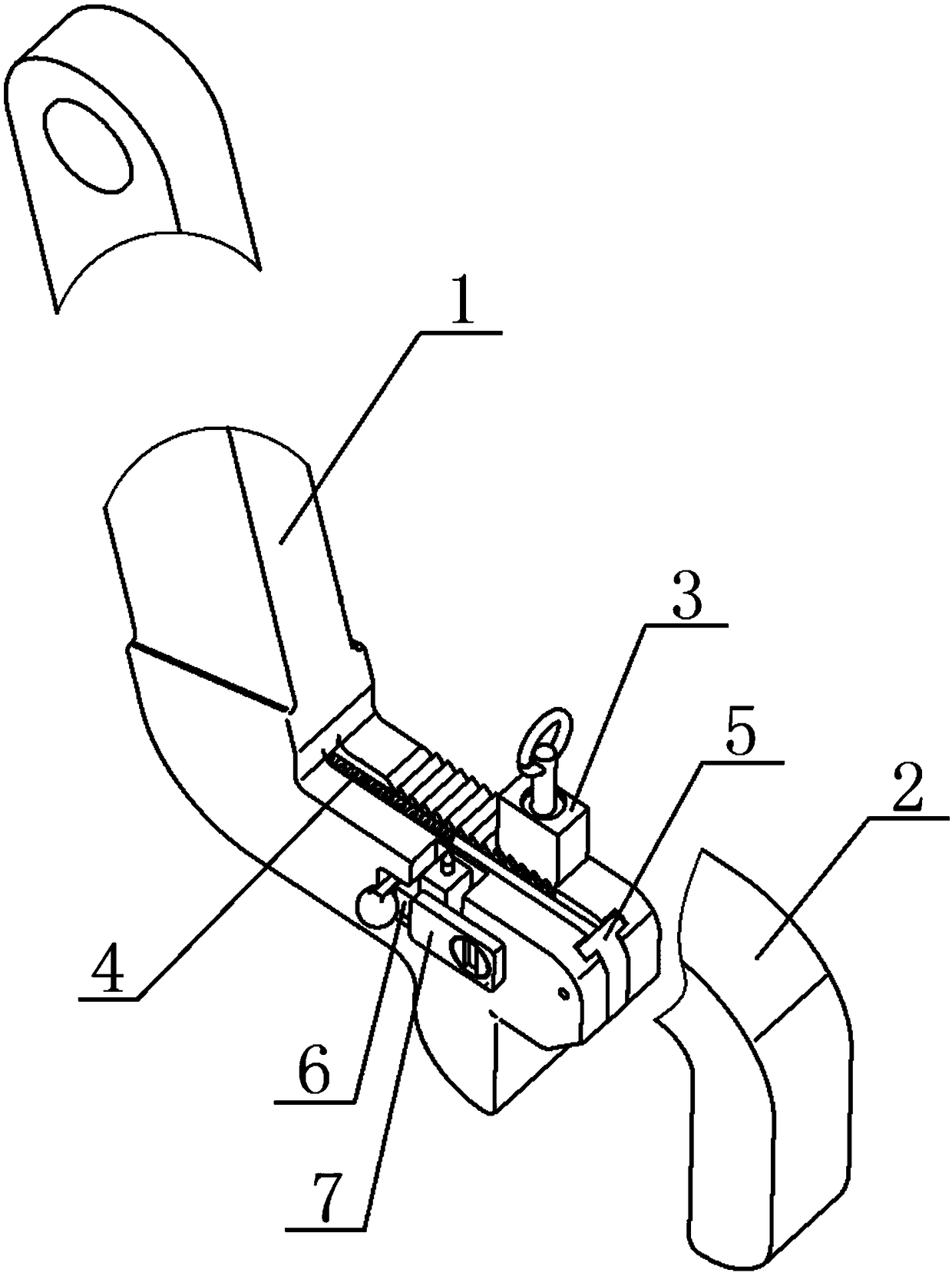

[0053] The invention provides a wrench with adjustable opening width, the schematic diagram of its overall structure is as follows figure 1 As shown, including the handle 1, the upper jaw part 2, the stopper 3, the drive spring 4, the limit plate 5 and the adjustment part 6, the upper jaw part 2, the drive spring 4, the limit plate 5 and the adjustment part 6 are all installed on the On the handle 1 , the stopper 3 is installed in the upper jaw part 2 .

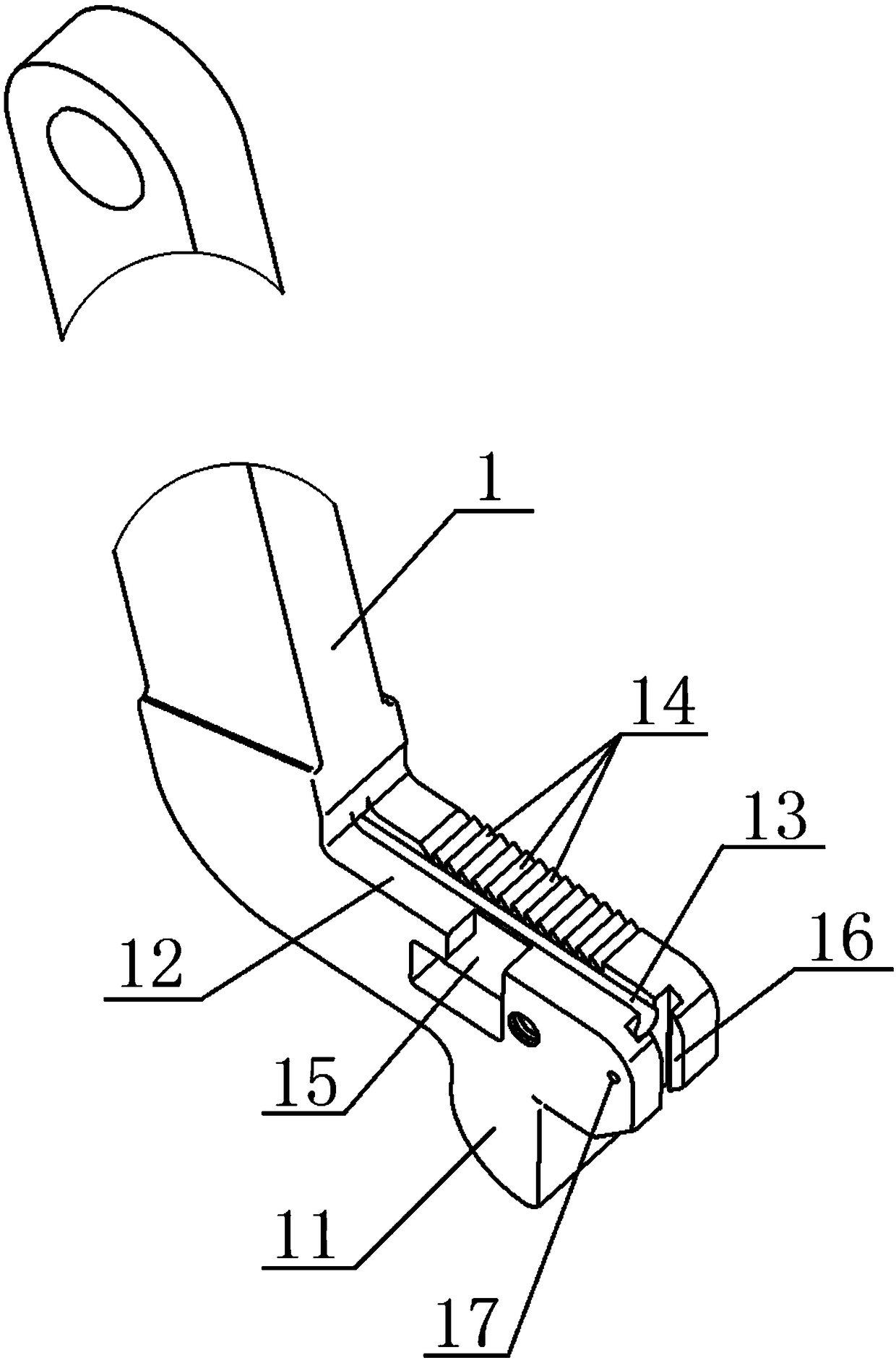

[0054] The structure diagram of the handle 1 is as follows figure 2As shown, the handle 1 is integrally provided with a lower jaw portion 11, and the side of the handle 1 opposite to the surface where the lower jaw portion 11 is located is an upper adjustment surface 12, and the upper adjustment surface 12 is provided with a groove that is as long as its length and has a cross-section of Ω type of sliding groove 13; one side of the sliding groove 13 is provided with a plurality of stop grooves 14 arranged linearly along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com