Ag-CuO/C catalyst and preparation and applications thereof

A catalyst, ag-cuo technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as ORR activity gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

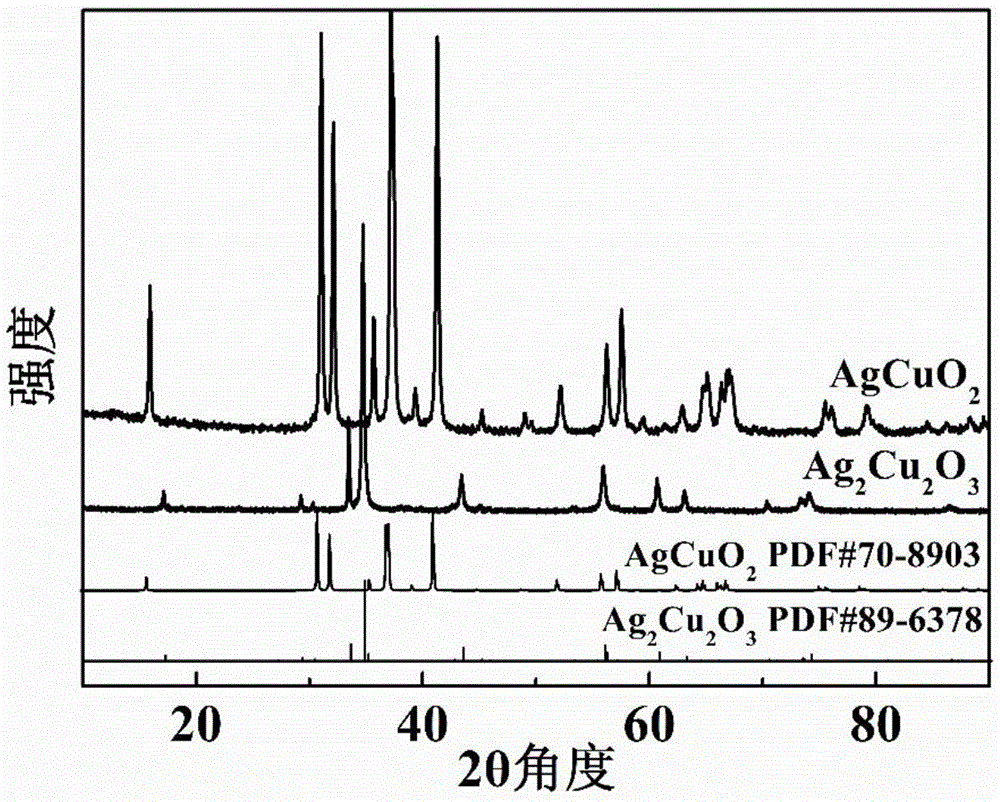

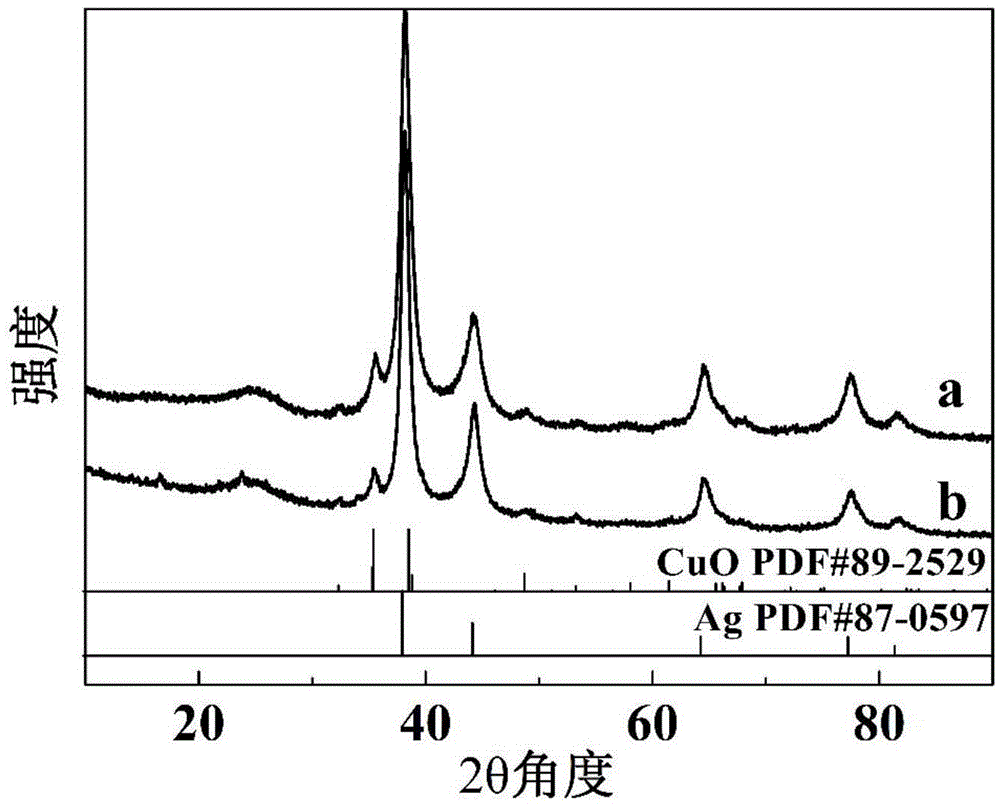

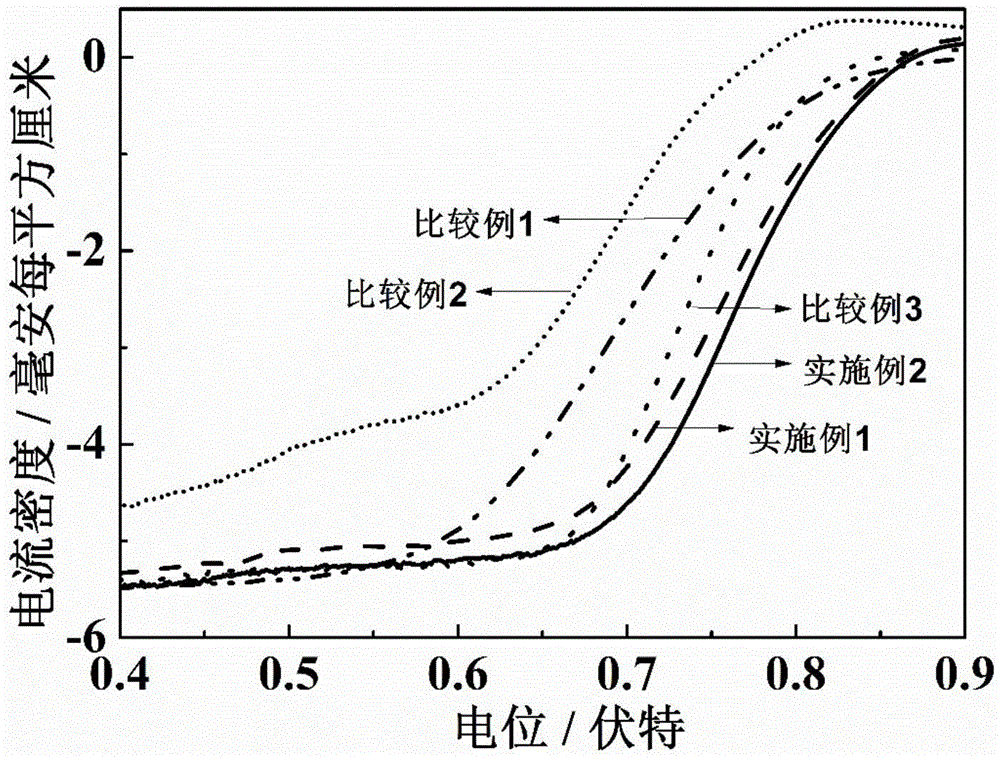

Embodiment 1

[0027] Embodiment 1: the AgCuO of 5mg 2 Ultrasonic dispersion in 6mL of ethanol, then adding 5 mg of VulcanXC-72R to it for ultrasonic dispersion, and finally adding 20 μL of 5wt.% nafion solution to obtain a catalyst precursor slurry after uniform dispersion. The catalyst slurry was drop-coated on a glassy carbon electrode, and it was scanned by cyclic voltammetry at 0.12V-1.2V (relative to the potential of the reversible hydrogen electrode) until the scanning curve was stable, and the loading of Ag was 27.62%, and the loading of CuO was 27.62%. Ag / CuO / C catalyst in an amount of 20.35%.

Embodiment 2

[0028] Embodiment 2: the Ag of 5mg 2 Cu 2 o 3 Ultrasonic dispersion in 6mL of ethanol, then adding 5 mg of VulcanXC-72R to it for ultrasonic dispersion, and finally adding 20 μL of 5wt.% nafion solution to obtain a catalyst precursor slurry after uniform dispersion. The catalyst slurry was drop-coated on a glassy carbon electrode, and it was scanned by cyclic voltammetry at 0.12V-1.2V (relative to the potential of the reversible hydrogen electrode) until the scanning curve was stable, and the loading of Ag was 28.19%, and the loading of CuO was 28.19%. Ag / CuO / C catalyst in an amount of 20.74%.

Embodiment 3

[0029] Embodiment 3: the AgCuO of 0.5mg 2 Ultrasonic dispersion in 6mL of ethanol, then 9.5mg of BlackPearls-2000 was added to it for ultrasonic dispersion, and finally 20 μL of 5wt.% PTFE solution was added to obtain a catalyst precursor slurry after uniform dispersion. The catalyst slurry was drop-coated on conductive glass, and it was scanned at -0.3V (relative to the reversible hydrogen electrode potential) until the scanning curve was stable, and the loading of Ag was 2.66%, and the loading of CuO was 1.96%. Ag / CuO / C catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com