Multifunctional agricultural farming machine

A cultivator and multi-functional technology, which is applied to agricultural machinery and implements, agriculture, shovels, etc., can solve the problems of large power consumption and many operations, and achieve the effect of reducing power consumption and improving operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

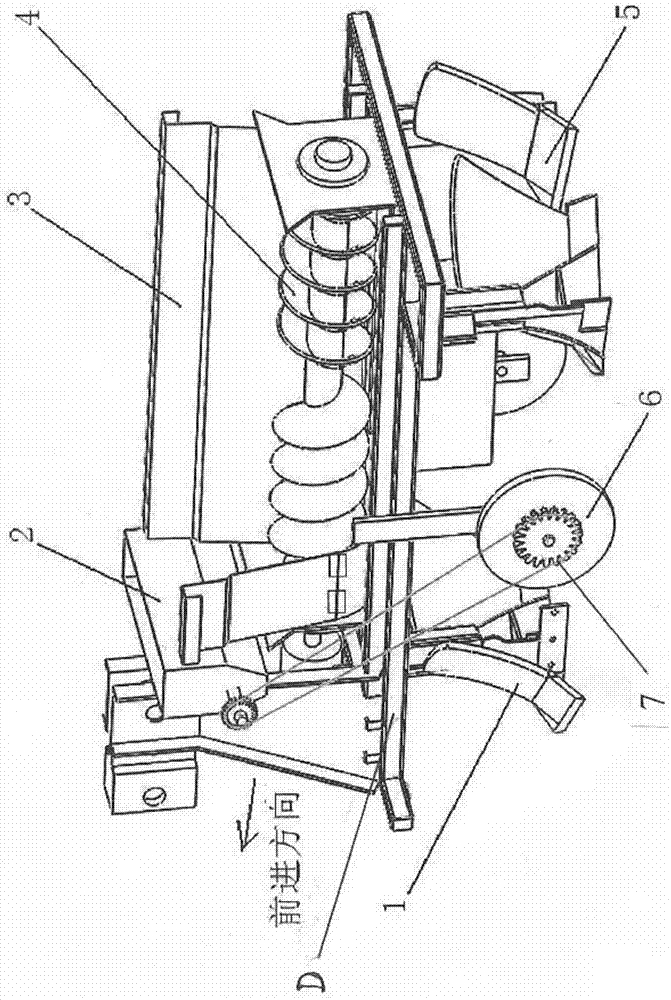

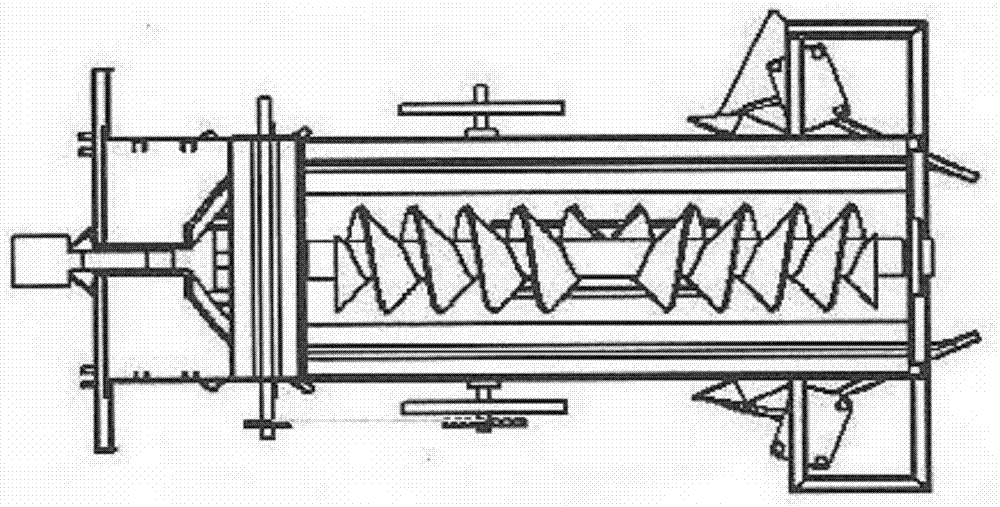

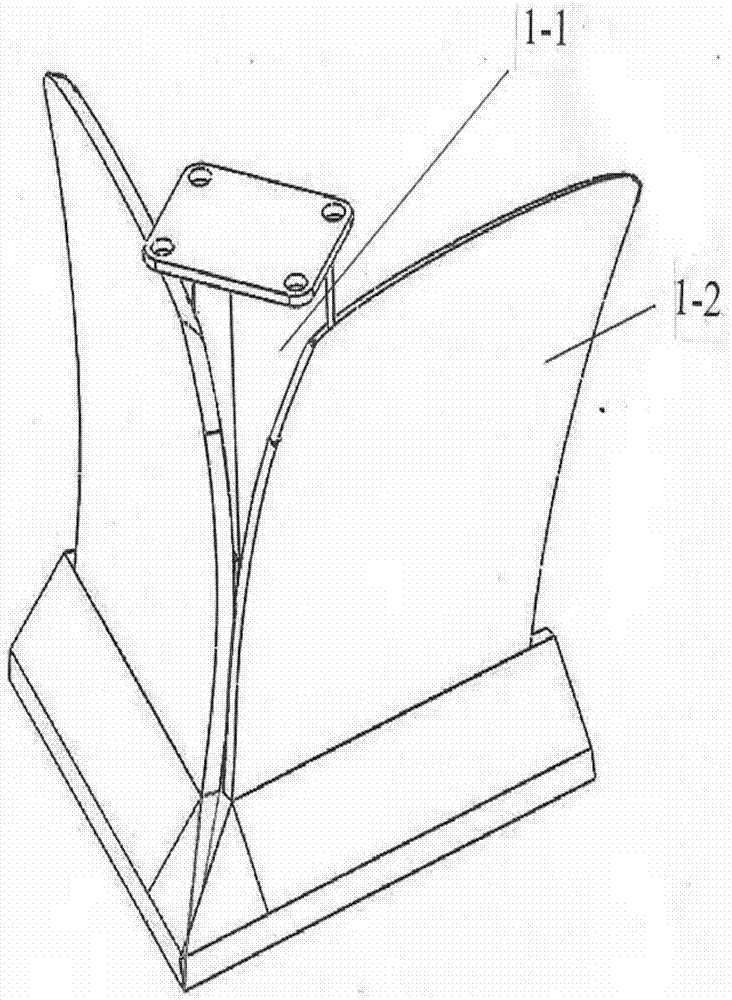

[0012] See figure 1 , 2 , install a furrowing plow 1 on the bottom of the frame D on which the traction mechanism is installed, that is, on the symmetrical surface along the forward direction of the implement, plow the soil in the plow layer, and divide the floating soil to both sides; the structure of the plow is as follows figure 2 As shown, the furrowing plow 1 is a pair of symmetrical plow bodies 1.2 installed on the same plow leg 1.1, so that the plowing resistance is in the same direction as the unit's forward direction, and excessive lateral force is avoided. Inorganic fertilizer box 2 is set above the frame D, and the lower part of the inorganic fertilizer box 2 is assembled using a fertilizer applicator (using known prior art, not shown in the figure), and the rotating shaft of the fertilizer applicator is connected to the ground through a sprocket wheel chain transmission mechanism 7. Wheel 6; see figure 1 , 4 , the organic fertilizer box 3 used to hold crushed s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap