Live-working electric high-branch pruning device

A technology of live work and pruning device, which is applied in the field of garden pruning, can solve the problems of large branches breaking structures or other objects, operators climbing and changing positions and falling high, gasoline high-branch saws are heavy, etc., achieving good pruning effect, flexible operation, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

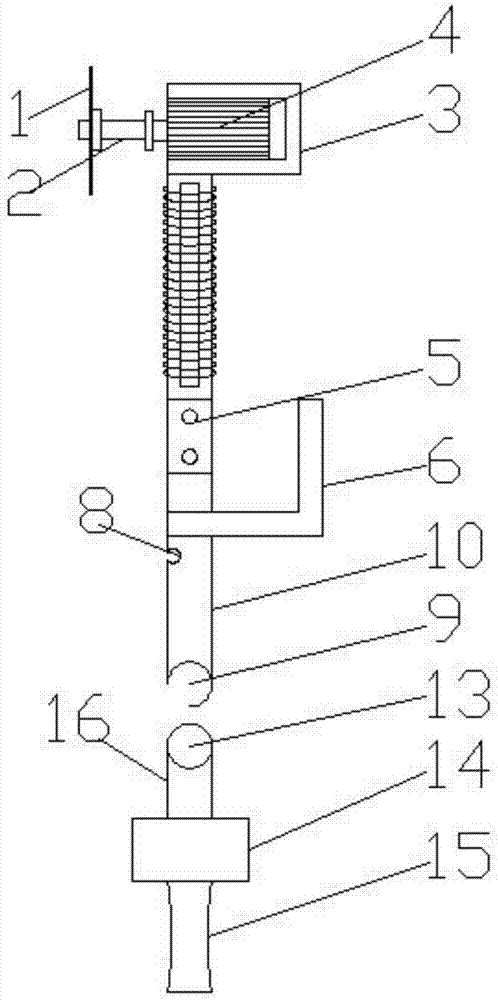

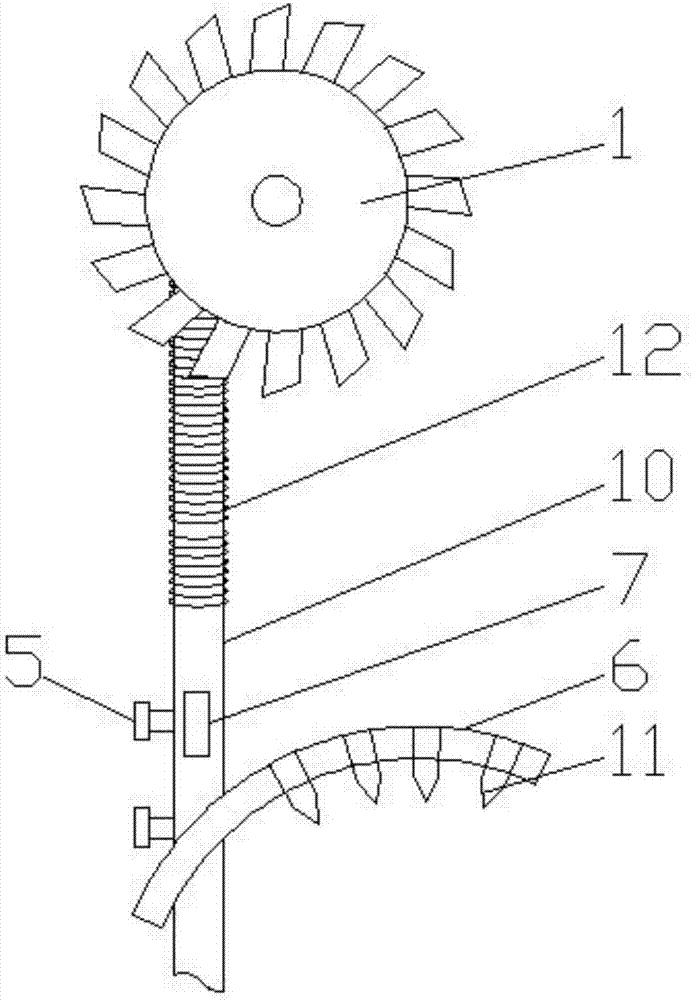

[0016] refer to Figure 1-2 , an electric high-branch pruner for live work, comprising an aluminum alloy round pipe 10 and an insulating rod 16, the insulating rod 16 is specifically a telescopic insulating operating rod connected to the aluminum alloy round pipe 10 by using a 5-8m telescopic insulating operating rod, Adjust the distance freely. And the aluminum alloy round pipe 10 and the insulating rod 16 are connected by a snap mechanism, the snap mechanism includes an aluminum alloy joint 9 and an aluminum alloy joint 13 of the insulating rod, and one end of the aluminum alloy joint 9 is installed on the aluminum alloy round pipe 10 One end of the insulating rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com