Wireless linear joint type automatic jet printing system

A articulated, straight line technology, applied in printing, printing devices, transfer materials, etc., can solve the problems of inconvenient production and operation, high price, etc., and achieve the effect of improving the level of automated production, good portability and developability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the present invention will be further described.

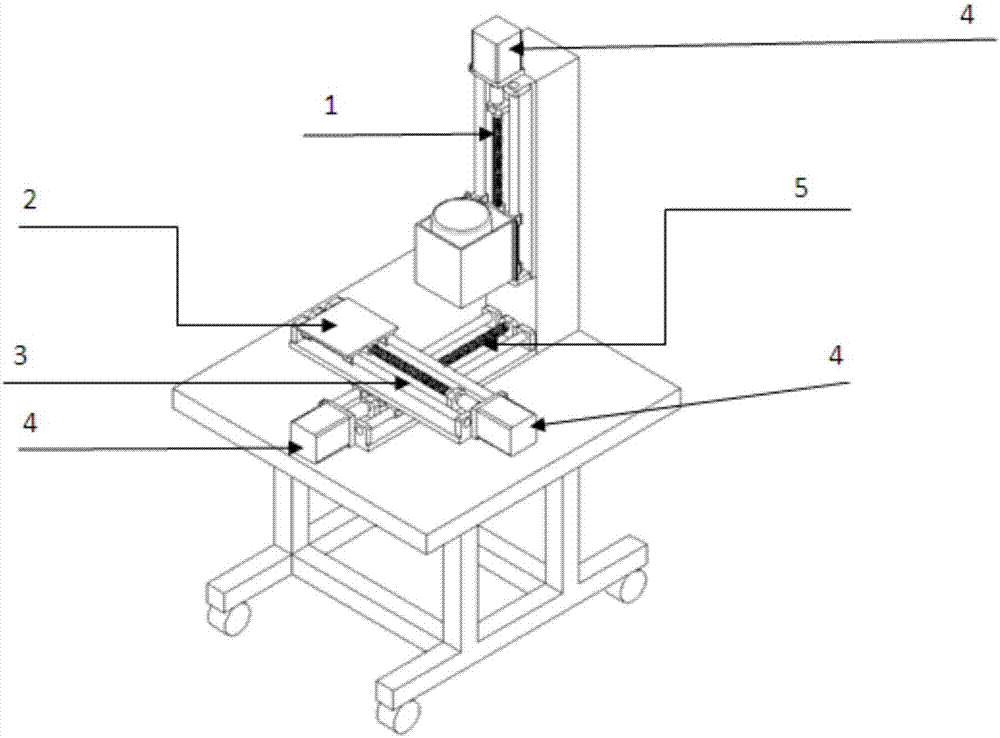

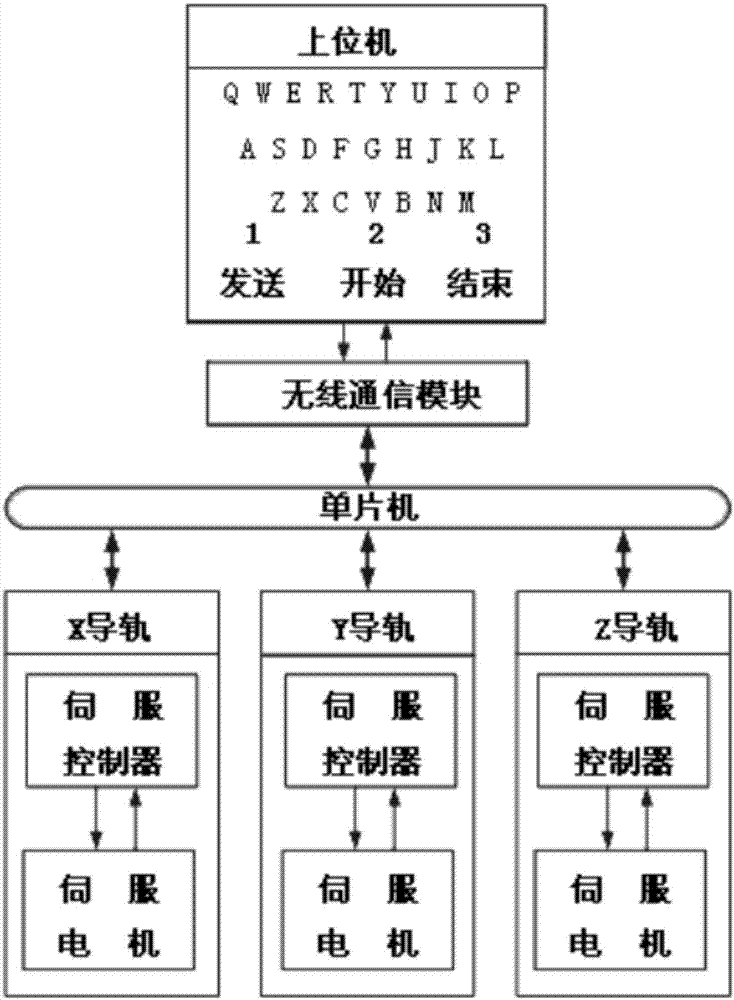

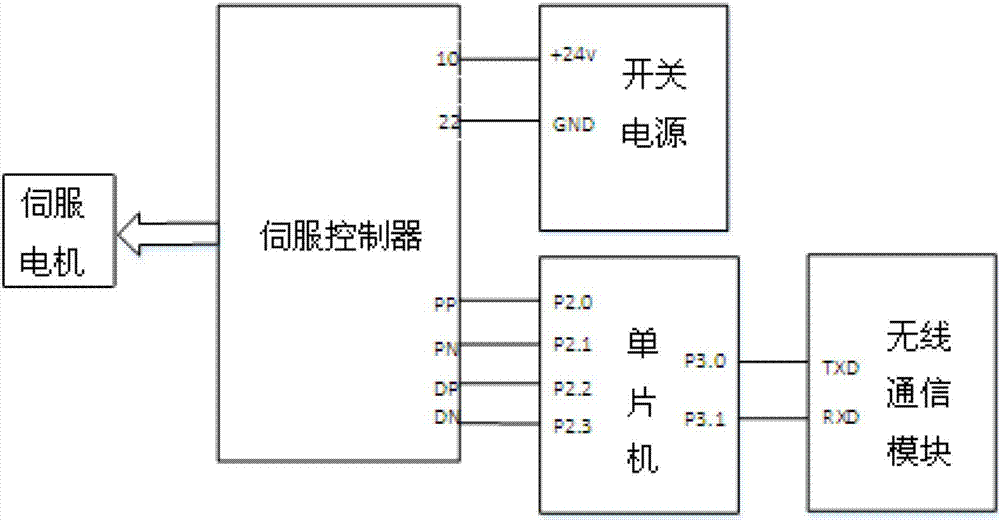

[0023] Such as Figure 1-4 As described above, a wireless linear joint type automatic printing system includes a working table, a host computer, a single-chip microcomputer, three servo controllers, three servo motors, a three-degree-of-freedom printing station and a wireless communication module. Each servo motor All are connected to the single-chip microcomputer through a servo controller, and the wireless communication module communicates between the single-chip microcomputer and the host computer. The three-degree-of-freedom printing table includes X guide rails, Y guide rails and Z guide rails, and Y guide rails are installed on the worktable. An X guide rail perpendicular to each other is installed on the Y guide rail, and the X guide rail moves laterally in the Y guide rail. A servo motor is connected to one end of the X guide rail, and an object stage is installed on the X gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com