Transfer printing processing method of periphery cambered 3D cover plate

A processing method, 3D technology, applied in the directions of transferring ink from the original manuscript, burning, etc., can solve the problems of single color of silk screen printing, insufficient adhesion, and difficulty in ink blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of the purpose, technical solutions and effects of the present invention, the present invention will now be further described in detail in conjunction with examples.

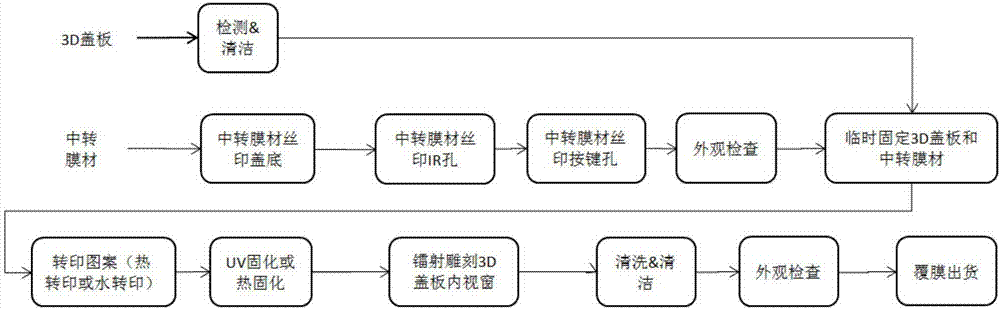

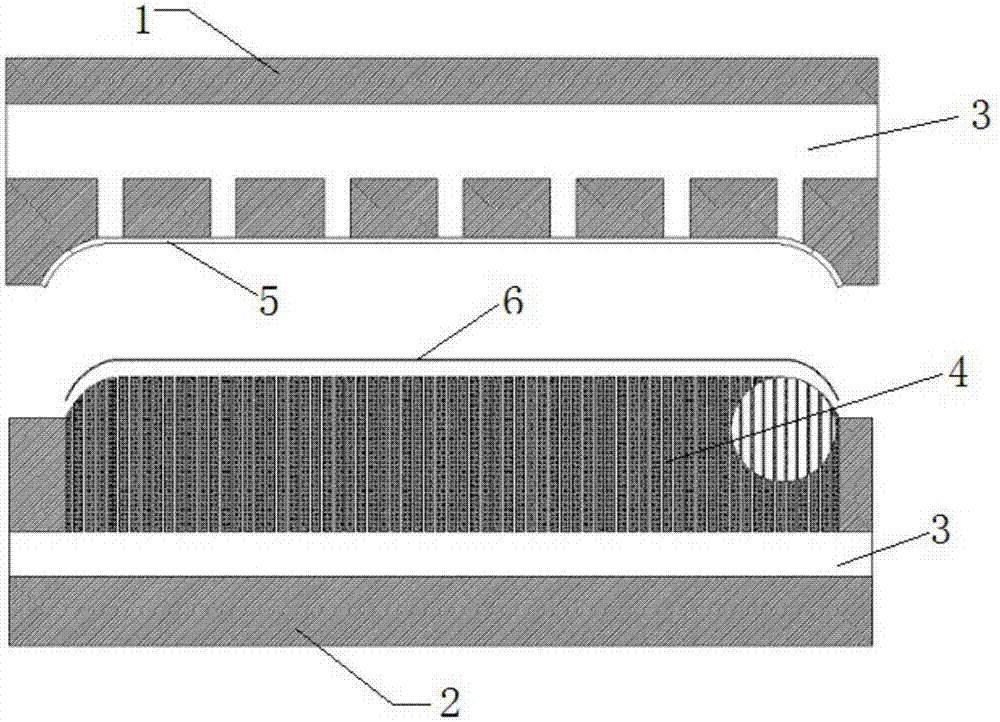

[0027] figure 1 A transfer printing processing method for a curved 3D cover plate with a surrounding surface is provided, which is used to transfer the ink pattern on the transfer film material to the 3D cover plate. The method includes the following steps:

[0028] Step 1), the detection and cleaning of 3D covers, the 3D covers that do not meet the requirements are cleaned, and the 3D covers that pass the inspection are selected for the next process; the equipment used in this step is a desk lamp.

[0029] Step 2), screen-print the bottom cover, IR holes, and button holes on the transfer film material in sequence through the screen printing equipment, and perform the appearance inspection of the transfer film material after the silk screen printing is completed; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com