Container lining packaging bag

A packaging bag and container technology, applied in the field of container lining packaging bags, can solve the problems of powdery cargo leakage, increased transportation costs, high labor costs, etc., to increase loading capacity, reduce working hours and labor costs, and reduce disposal The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

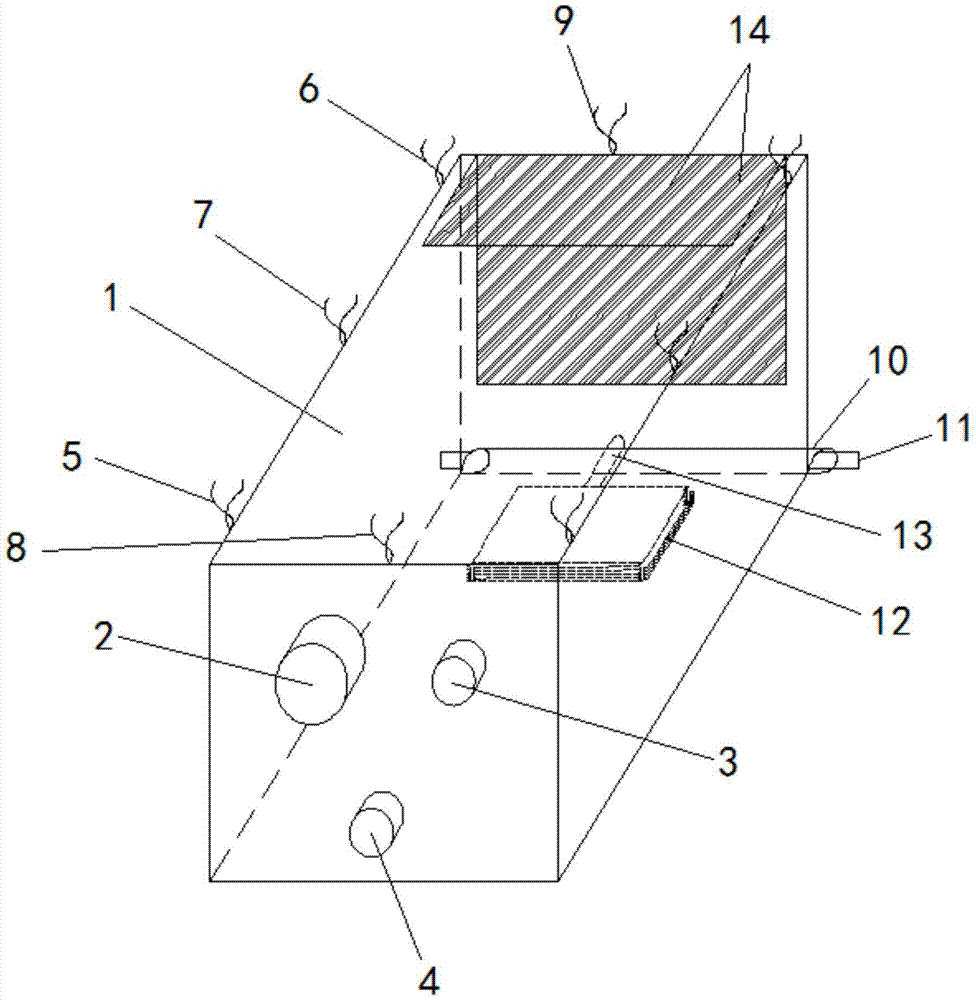

[0015] like figure 1 As shown, in the first embodiment of the container liner packaging bag of the present invention, the container liner packaging bag 1 is used to be sleeved in the container to hold powdered goods, and the liner packaging bag 1 is a hollow cylindrical film composed of Or a rectangular parallelepiped packaging bag, the first end surface of the lining packaging bag 1 is provided with a feed port 2 and a vent 3 communicating with the lining packaging bag 1, and the lower part of the first end surface of the packaging bag 1 is provided with the The discharge port 4 connected to the liner packaging bag 1 is provided with a first corner lanyard 5, a second corner lanyard 6, And the first middle lanyard 7 between the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com