Desulfurization waste water zero discharging system and process for realizing in-house by-product recycling treatment

A desulfurization wastewater and desulfurization system technology, applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of failure to achieve zero discharge, increase system operating costs, and unreasonable use of resources. Achieve the effects of reducing operating costs, reducing disposal costs, and achieving significant economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

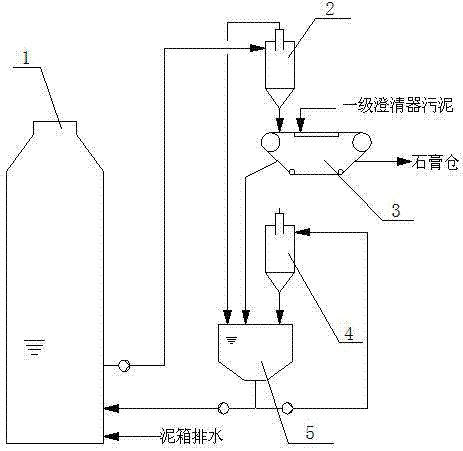

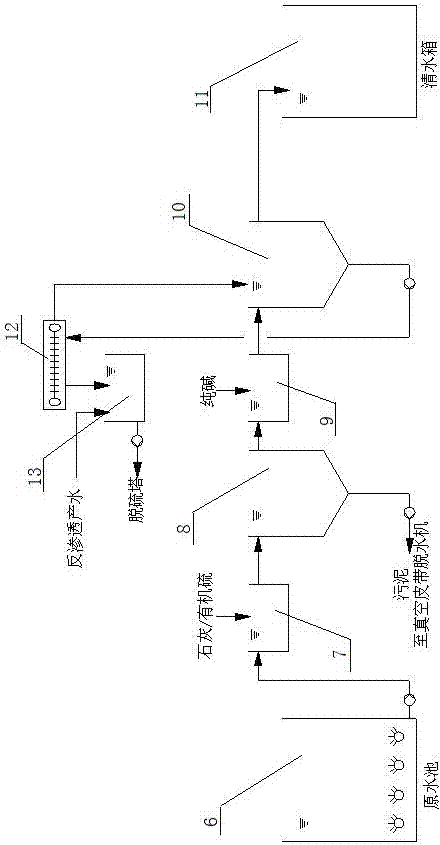

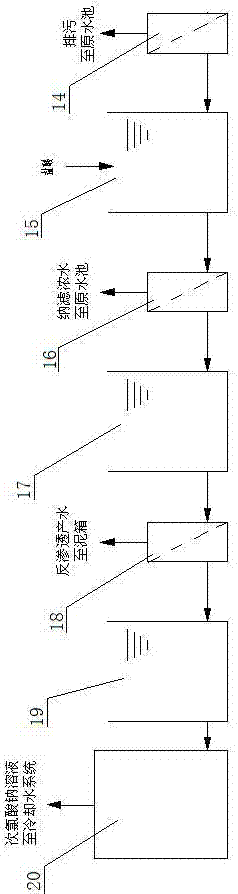

[0037] Such as Figure 1 to Figure 3 A desulfurization wastewater zero-discharge system that realizes in-plant resource disposal of by-products is shown, including a flue gas desulfurization system, a zero-discharge pretreatment system for desulfurization wastewater, and a zero-discharge advanced treatment system for desulfurization wastewater:

[0038] The flue gas desulfurization system includes a desulfurization tower 1, a gypsum cyclone 2, a vacuum belt dehydrator 3, a waste water cyclone 4 and a return water tank 5, the desulfurization tower 1 is connected to the gypsum cyclone 2, and the A vacuum belt dehydrator 3 is provided below the gypsum cyclone 2, and both the gypsum cyclone 2 and the vacuum belt dehydrator 3 are connected with a backflow water tank 5, and the backflow water tank 5 is connected with a waste water cyclone 4;

[0039] The desulfurization wastewater zero-discharge pretreatment system includes a raw water pool 6, a primary reaction tank 7, a primary cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com