High-smooth styrene-acrylic emulsion for coated paper surface coating and preparation method thereof

A technology of styrene-acrylic emulsion and coated paper, which is applied in the field of coatings, and can solve the problems of low-temperature film-forming properties, anti-sticking smoothness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

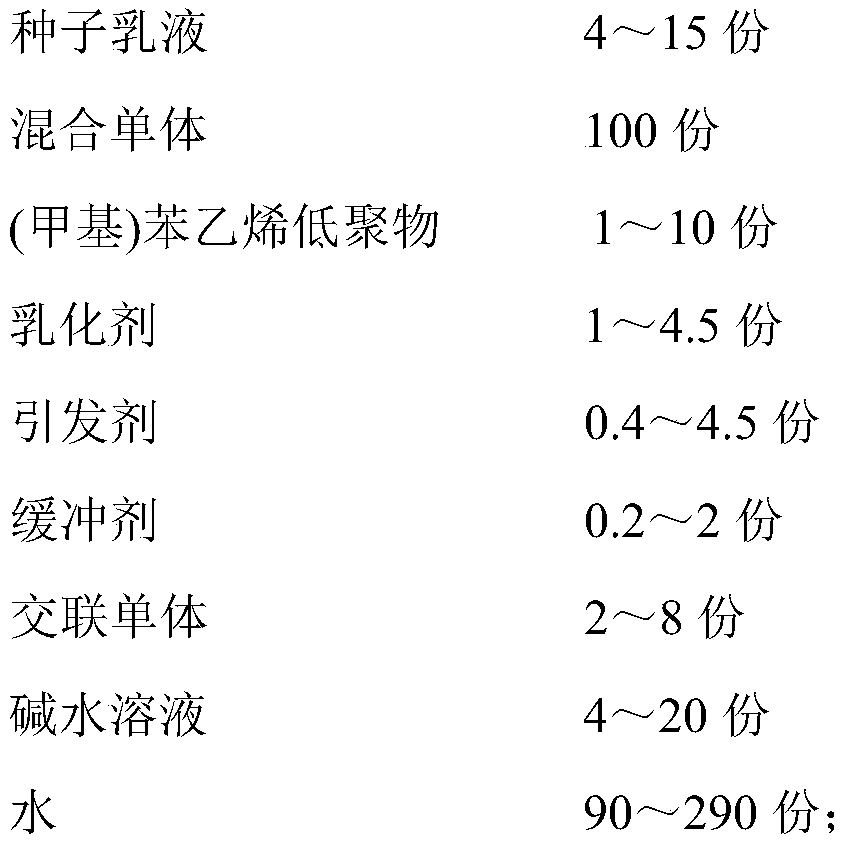

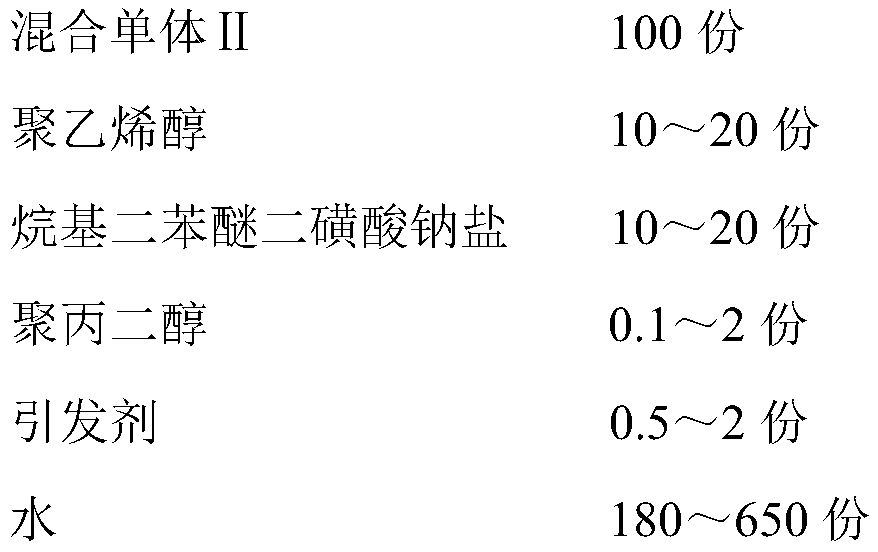

Method used

Image

Examples

Embodiment 1

[0074] 1) Synthesis of seed emulsion:

[0075] a) Mix 12 g of n-butyl acrylate and 85 g of styrene to obtain mixed monomer II.

[0076] b) 10g polyvinyl alcohol 0588 (Guangzhou Qisheng Chemical Co., Ltd.), 10g disodium dodecyl diphenyl ether disulfonate (Rhodia), 0.1g polypropylene glycol PPG-200 (Jiangsu Haian Petrochemical Co., Ltd. Plant), 0.5g of potassium persulfate and 180.9g of deionized water were mixed, kept at 90°C for 10 minutes, and the mixed monomer II in step a) was added.

[0077] c) heat preservation at 90° C. for 1 hour, cool down to 25° C., and filter through a 100-mesh sieve to obtain a seed emulsion.

[0078] 2) Synthesis of polystyrene:

[0079] a) Add 0.5g of azobisisobutyronitrile into 100g of isopropanol to fully dissolve and raise the temperature to 70-80°C.

[0080] b) slowly drop 50g of styrene into the solution in step a) for 2 hours at a constant speed, and control the temperature at 80°C

[0081] c) Keep warm at 70-90°C for 0.5 hours.

[0082...

Embodiment 2

[0086] 1) Synthesis of seed emulsion:

[0087] a) Mix 5 g of ethyl acrylate and 95 g of methyl styrene to obtain mixed monomer II.

[0088] b) 20g polyvinyl alcohol 1788 (Guangzhou Qisheng Chemical Co., Ltd.), 20g disodium dodecyl diphenyl ether disulfonate (Rhodia), 2g polypropylene glycol PPG-400 (Jiangsu Haian Petrochemical Plant) ), 2g of ammonium persulfate and 576g of deionized water were mixed, kept at 90°C for 30 minutes, and the mixed monomer II in step a) was added.

[0089] c) heat preservation at 90° C. for 3 hours, cool down to 25° C., and filter through a 100-mesh sieve to obtain a seed emulsion.

[0090] 2) Synthesis of polymethylstyrene:

[0091] a) Add 1 g of azobisisovaleronitrile into 120 g of isopropanol to fully dissolve and raise the temperature to 70-80°C.

[0092] b) Slowly add 50 g of methyl styrene to the solution in step a) dropwise at a constant speed for 1.5 hours, with the temperature controlled at 80°C

[0093] c) Incubate at 70-90°C for 1 ho...

Embodiment 3

[0098] 1) Synthesis of seed emulsion:

[0099] a) Mix 5 g of methyl methacrylate, 5 g of 2-ethylhexyl acrylate, and 90 g of methylstyrene to obtain mixed monomer II.

[0100] b) 15g polyvinyl alcohol 2488 (Guangzhou Qisheng Chemical Co., Ltd.), 15g disodium dodecyl diphenyl ether disulfonate (Rhodia), 1g polypropylene glycol PPG-600 (Jiangsu Haian Petrochemical Plant) ), 1g of sodium persulfate and 308g of deionized water were mixed, kept at 80°C for 20 minutes, and the mixed monomer II in step a) was added.

[0101] c) heat preservation at 80° C. for 2 hours, cool down to 25° C., and filter through a 100-mesh sieve to obtain a seed emulsion.

[0102] 2) Synthesis of polystyrene:

[0103] a) Add 1 g of azobicyclohexylcarbonitrile into 150 g of isopropanol to fully dissolve and raise the temperature to 75°C.

[0104] b) Slowly add 50g of methyl styrene dropwise to the solution in step a), dropwise at a constant speed for 1.5 hours, and control the temperature at 75°C

[010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com