Ion nitriding heat treatment process of fv520b material

A FV520B, ion nitriding technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., to achieve the effect of improving bearing capacity and fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

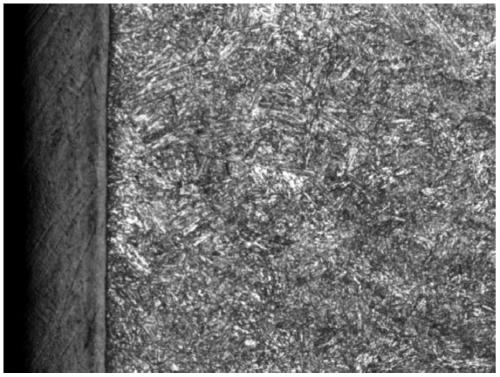

Embodiment 1

[0029] The chemical composition of the FV520B material used in this example: C: 0.04wt.%; Si: 0.42wt.%; Mn: 0.74wt.%; S: 0.005wt.%; P: 0.021wt.%; Cr: 13.80wt.%. %; Mo: 1.46wt.%; Ni: 5.39wt.%; Cu: 1.49wt.%; Nb: 0.30wt.%; It is subjected to ion nitriding heat treatment, including the following steps:

[0030] (1) solution treatment, at 1050 ℃, heat preservation for 2 hours, then air cooling;

[0031] (2) Adjustment treatment, heat preservation at 850°C for 2.5 hours, and then oil cooling;

[0032] (3) Ion nitriding treatment, ion nitriding at 530°C for 18.0 hours, furnace cooling down to 200°C, and then out of the furnace and air cooling;

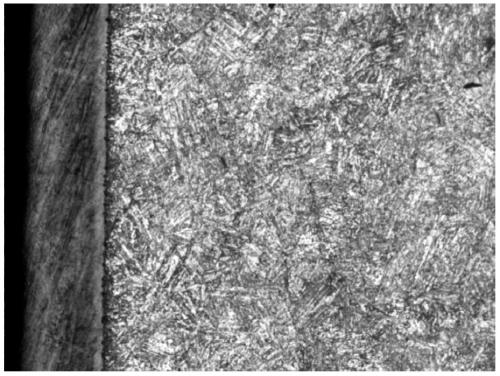

Embodiment 2

[0041] The chemical composition of the FV520B material used in this example: C: 0.04wt.%; Si: 0.42wt.%; Mn: 0.74wt.%; S: 0.005wt.%; P: 0.021wt.%; Cr: 13.80wt.%. %; Mo: 1.46wt.%; Ni: 5.39wt.%; Cu: 1.49wt.%; Nb: 0.30wt.%; It is subjected to ion nitriding heat treatment, including the following steps:

[0042] (1) solution treatment, at 1050 ℃, heat preservation for 2 hours, then air cooling;

[0043] (2) Adjustment treatment, heat preservation at 850°C for 2.5 hours, and then oil cooling;

[0044] (3) Ion nitriding treatment, ion nitriding at 530°C for 20.0 hours, furnace cooling down to 200°C, and then air cooling out of the furnace;

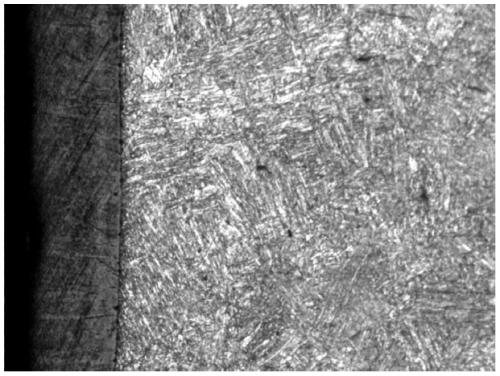

Embodiment 3

[0053] The chemical composition of the FV520B material used in this example: C: 0.04wt.%; Si: 0.42wt.%; Mn: 0.74wt.%; S: 0.005wt.%; P: 0.021wt.%; Cr: 13.80wt.% %; Mo: 1.46wt.%; Ni: 5.39wt.%; Cu: 1.49wt.%; Nb: 0.30wt.%; Ion nitriding heat treatment at different temperatures was carried out, including the following steps:

[0054] (1) solution treatment, at 1050 ℃, heat preservation for 2 hours, then air cooling;

[0055] (2) Adjustment treatment, heat preservation at 850°C for 2.5 hours, and then oil cooling;

[0056] (3) Ion nitriding treatment, ion nitriding at 500°C for 20.0 hours, furnace cooling down to 200°C, and then out of the furnace and air cooling;

[0057] See Table 5 for the infiltrated layer index of the tested example 3FV520B material after ion nitriding heat treatment, ion nitriding at 500°C also has a better infiltrated layer depth, the surface hardness is greatly improved, and the core hardness is also higher.

[0058] Table 5 Example 2 The permeation perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com