Oil cylinder barrel electric brushing plating repairing device

An electric brush plating and cylinder technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of high consumption of manpower, material and financial resources, efficiency and poor surface quality of repair, increase of measurement error, etc., to save Electroplating solution, avoid waste, small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

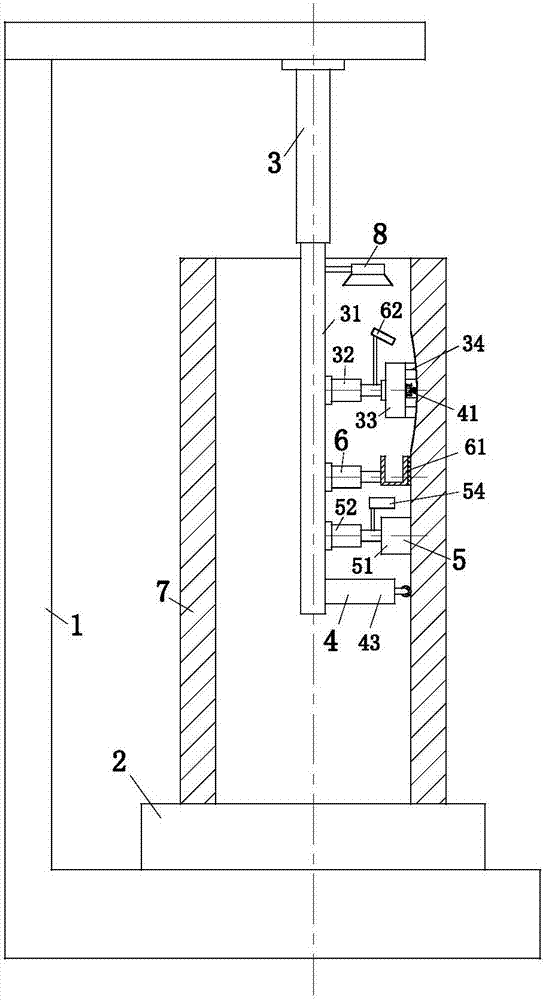

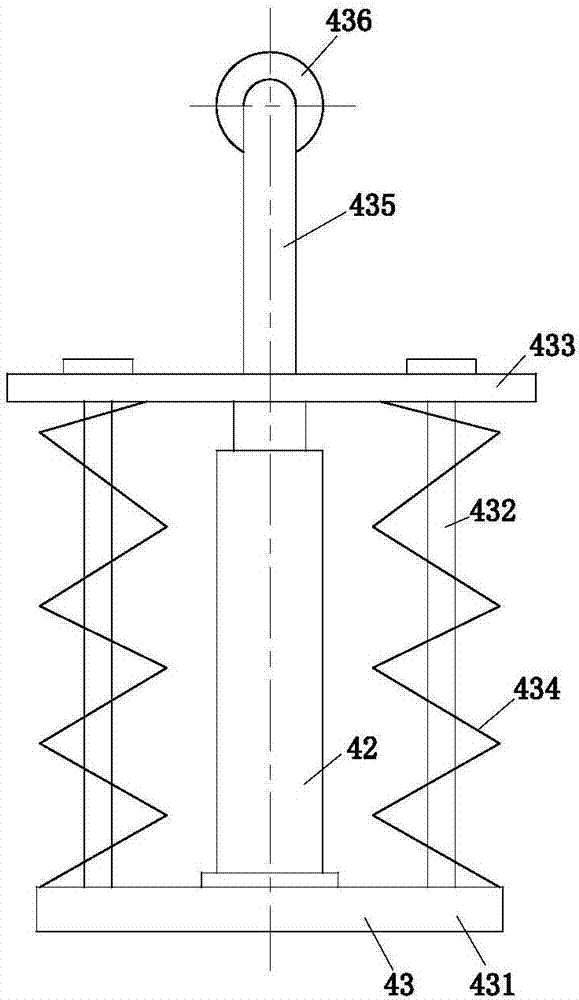

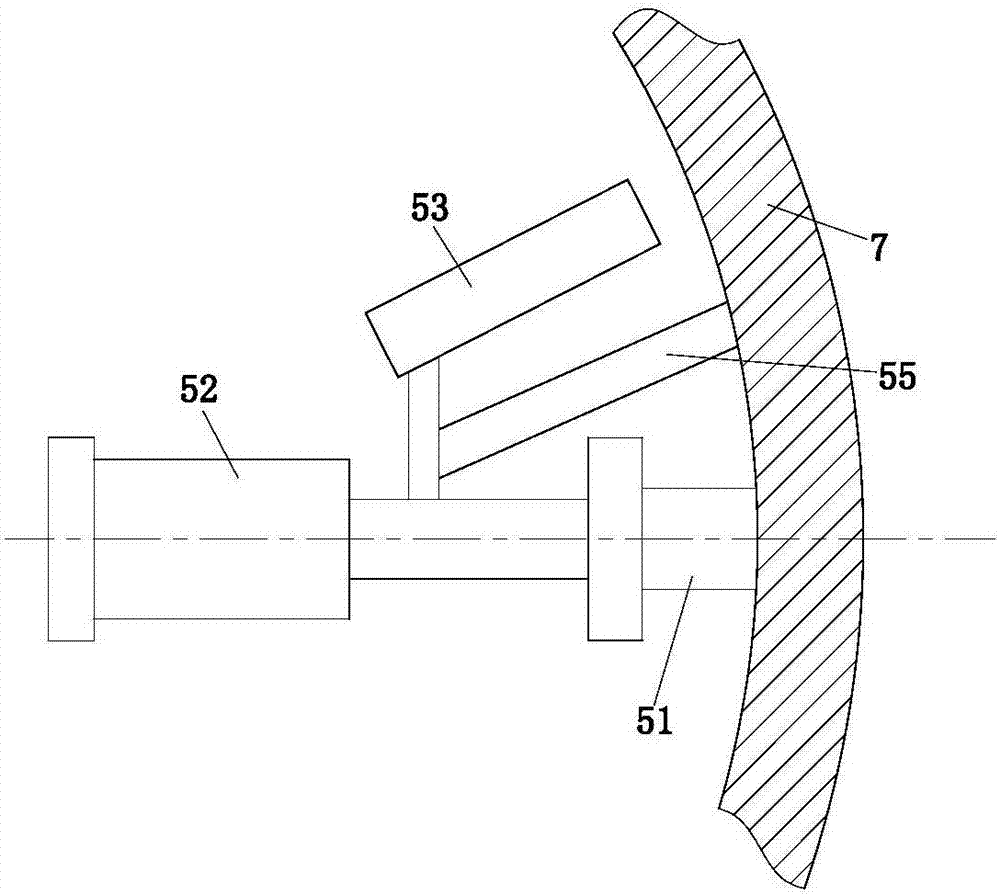

[0030] like figure 1 As shown, a brush plating repair device for an oil cylinder barrel according to the present invention includes a body 1, a rotary table 2, an electroplating unit 3, a detection unit 4, a painting unit 5, a circulating liquid supply unit 6 and a control unit, The cylinder 7 is installed vertically on the rotary table 2 and can rotate around its own axis; the electroplating unit 3 is used to repair the damaged part of the cylinder 7 by brushing; the detection unit 4 is used for To detect the damaged position of the cylinder 7 and detect the repair condition of the cylinder 7 in real time; the paint brushing unit 5 can spray insulating paint to separate the damaged part of the cylinder 7 from the intact part, After the repair is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com