Multi-pass waterproof sealing method for dewatering well of mass raft foundation

A technology of raft foundation and dewatering well, which is applied in basic structure engineering, earthwork drilling, sealing/isolation, etc., can solve problems such as high cost, hidden dangers of quality and safety, poor quality assurance of secondary treatment, etc., and achieve a success rate High, to avoid the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A multi-channel waterproof plugging method for a dewatering well of a thick and large raft foundation, comprising the following steps:

[0045] 1. Steel casing production:

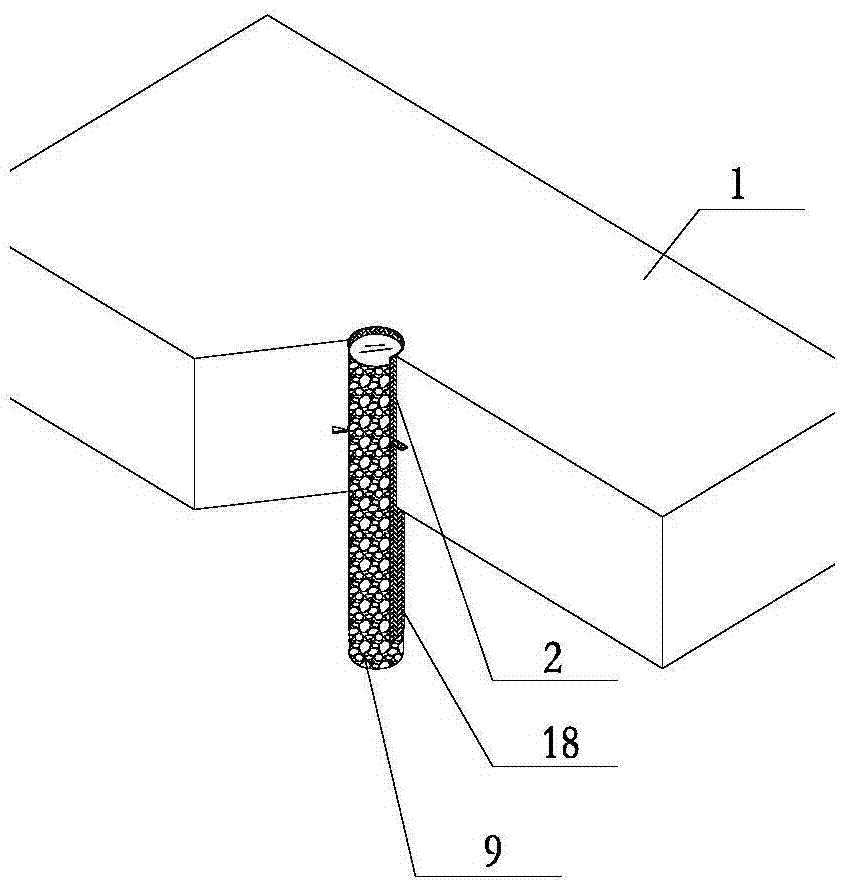

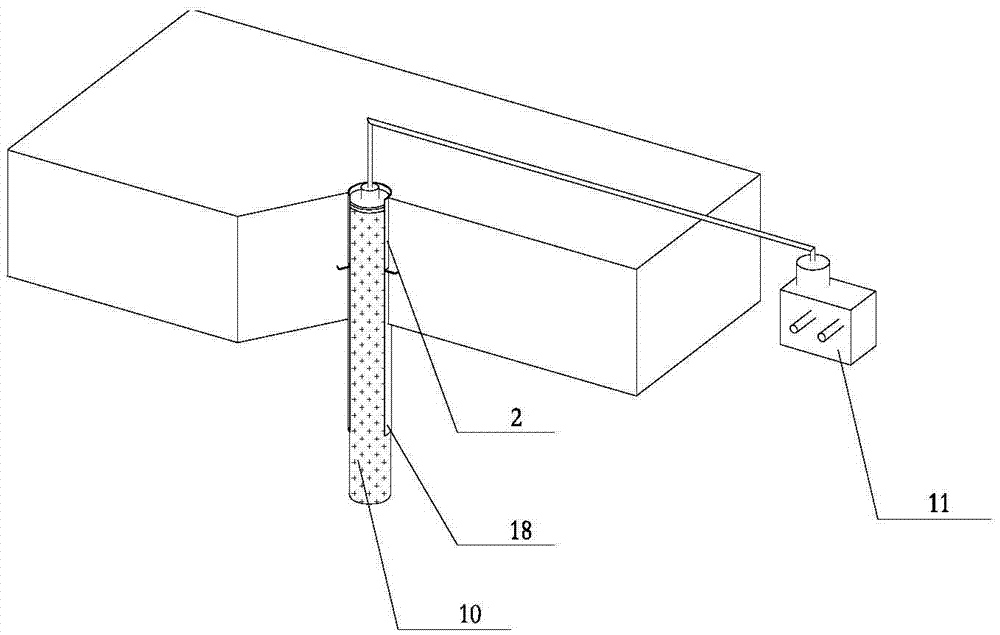

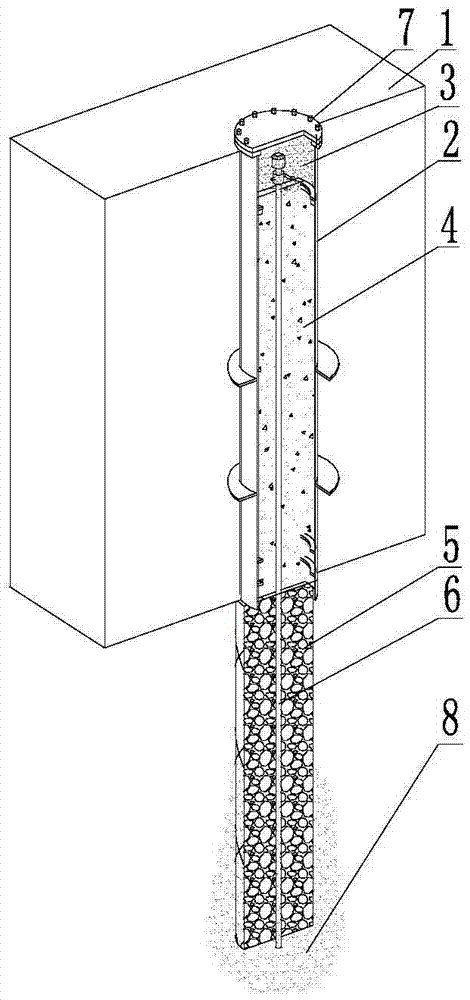

[0046] like Pic 4-1 , Figure 4-2 Shown: make the steel casing to be installed on the upper part of the dewatering well pipe in the raft foundation. It consists of a flange and an end cover 15 . The outer wall water stop ring is welded on the outer wall of the pipe, the two inner wall water stop rings are respectively welded on the upper and lower ends of the inner wall of the pipe, and the upper end flange and the end cover are installed on the top of the pipe body;

[0047] 2. Steel casing placement: During the construction of the foundation cushion, such as Figure 5 As shown, the steel casing is installed on the upper part of the cement-free sand pipe dewatering well pipe, the root of the foundation cushion is smeared into a figure-eight shape, and the water stop ring on the outer wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com