A prefabricated assembled reinforced concrete frame structure support and reinforcement node member

A reinforced concrete and frame structure technology, applied in building construction, construction, building maintenance, etc., can solve the problems of stress concentration in the core area of frame beam-column joints, complicated construction of joint outer steel, long construction period, etc., and save construction time. and cost, avoid adverse effects, purchase and process the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

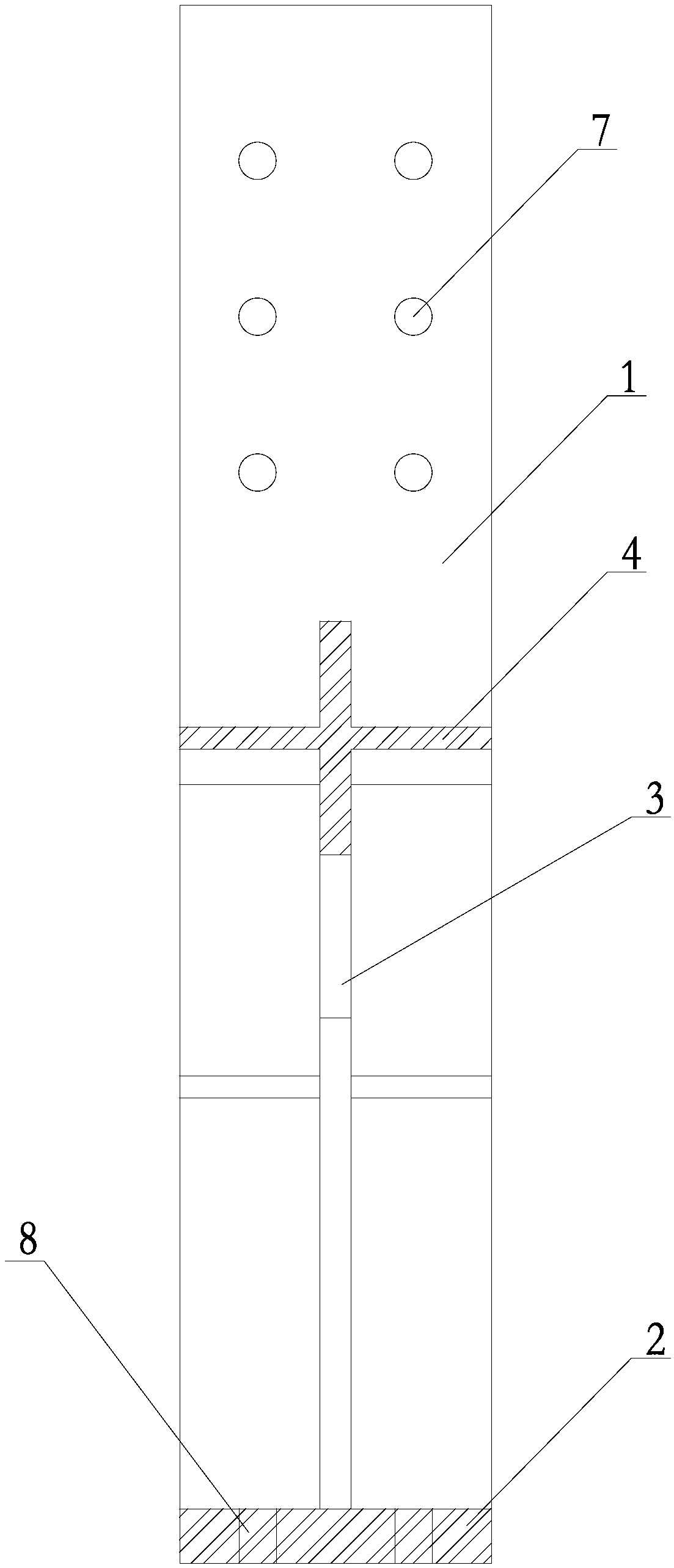

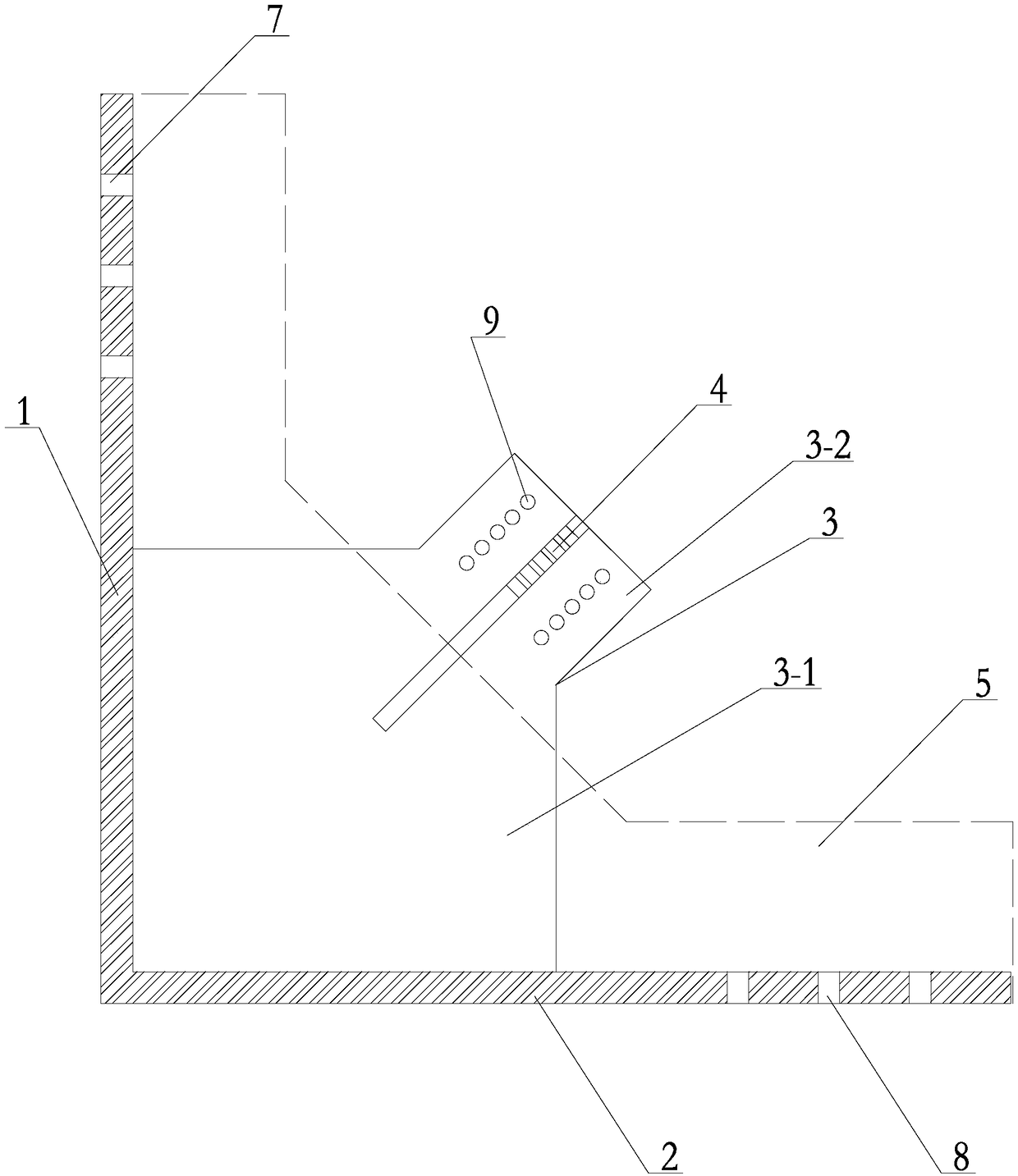

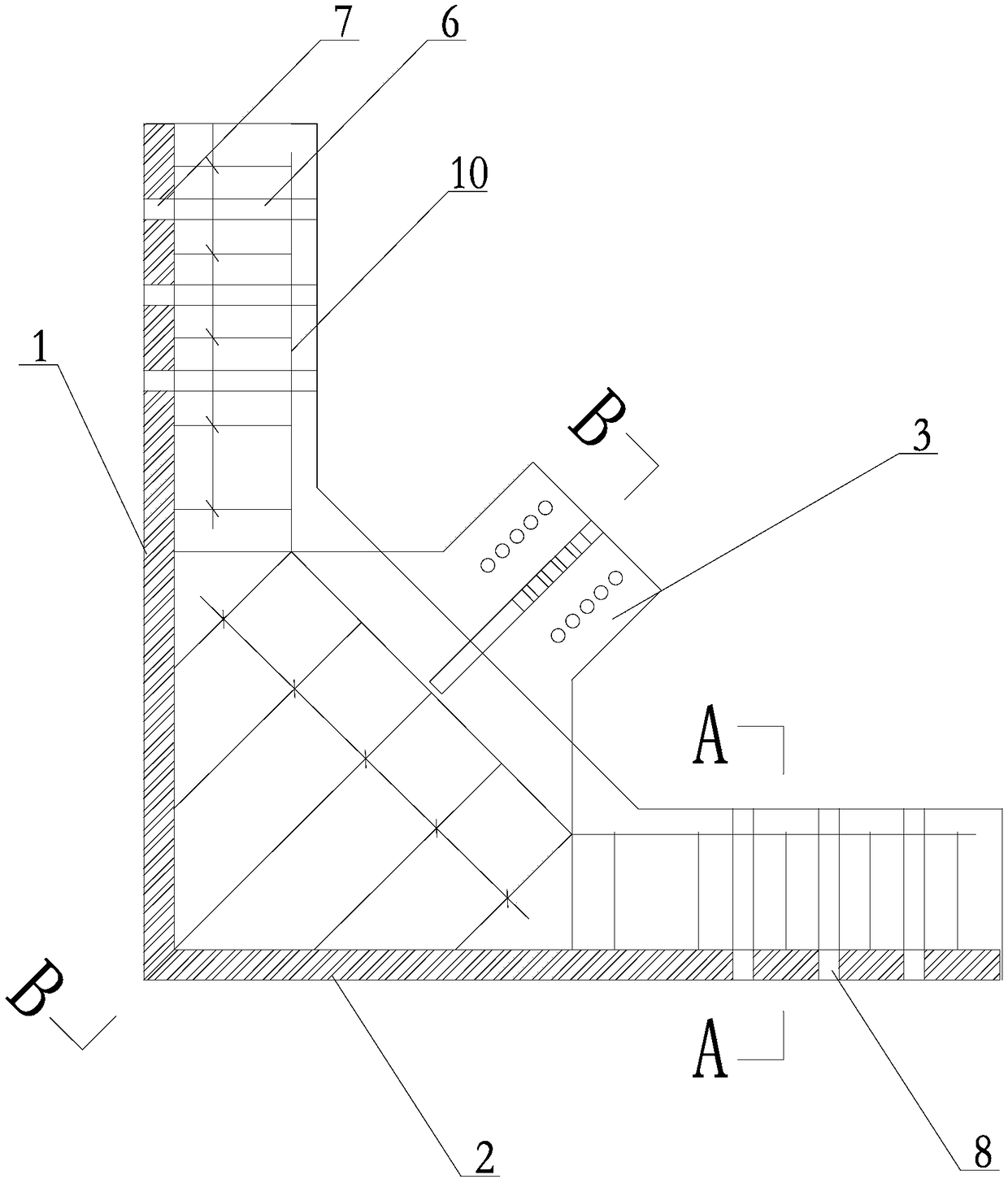

[0020] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment, this embodiment includes first steel plate 1, second steel plate 2, support gusset plate 3, gusset plate stiffener 4, concrete 5, multiple pre-embedded steel pipes 6, multiple reinforcing longitudinal bars 10, multiple first A reinforcing stirrup 11 and a plurality of second reinforcing stirrups 12, the first steel plate 1 is vertically welded to one end of the second steel plate 2 arranged horizontally, a plurality of first reserved holes 7 are opened on the top of the first steel plate 1, and the first steel plate 1 The other end of the second steel plate 2 is provided with a plurality of second reserved holes 8, and a pre-embedded steel pipe 6 is respectively inserted and welded in each first reserved hole 7 and each second reserved hole 8 for realizing node components Bolt connection with the beam column, the inner diameter of the pre-embedded steel pipe 6 is the same as the di...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination Figure 3 to Figure 8Describe this embodiment, a plurality of first reinforcing stirrups 11 of this embodiment are welded on the first steel plate 1 and the second steel plate 2, and one end of a plurality of second reinforcing stirrups 12 is welded on the first steel plate 1 and the second steel plate 2, the other ends of multiple second reinforcing stirrups 12 are welded on the supporting gusset plate 3, and multiple reinforcing longitudinal bars 10 pass through and are tied to multiple first reinforcing stirrups 11 and multiple second reinforcing stirrups 12 superior. With such arrangement, it is convenient to provide frame support for the poured concrete, meanwhile, the strength of the joint is increased and the service life is long. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 6 To illustrate this embodiment, the reinforced longitudinal bar 10 of this embodiment includes a vertical section steel bar 10-1, an inclined section steel bar 10-2 and a horizontal section steel bar 10-3, a vertical section steel bar 10-1, and an inclined section steel bar 10-2 The steel bar 10-3 in the horizontal section is sequentially fixed and integrated, and the prefabricated steel bar 10 is formed by a steel bar bending machine. Such setting facilitates matching with the structure of the node components to be prefabricated. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com