Method for gas prevention and treatment during stoping period of coal mining working face of coal mine

A coal mining face and gas technology, which is applied in mining equipment, earthwork drilling, wellbore lining, etc., can solve the problems of high cost of funds, tight drainage and replacement, and only 10-25% of the problem, so as to reduce the gas overrun , Suppress gas gushing, improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

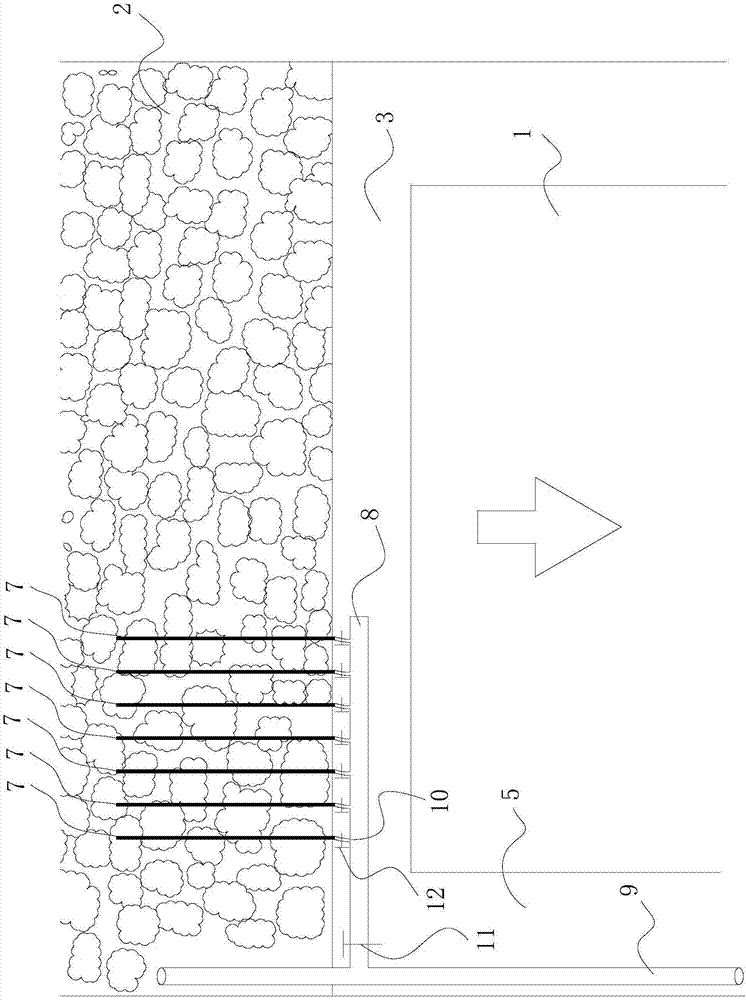

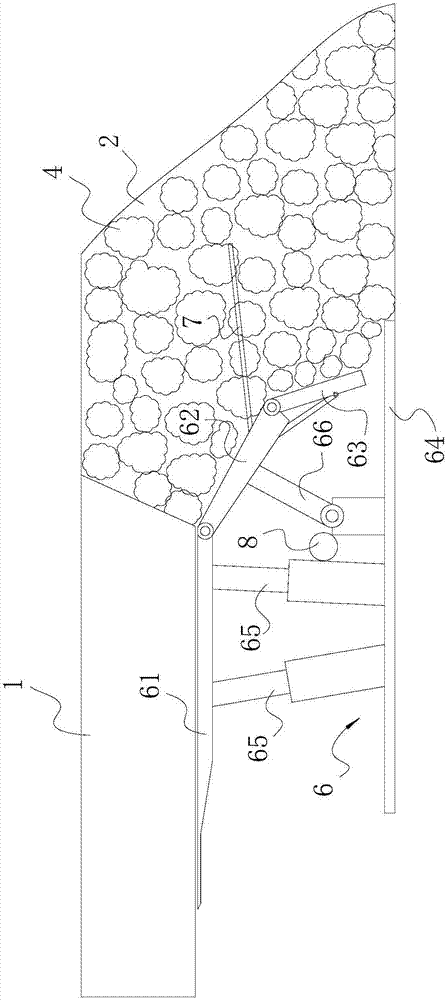

[0020] see figure 1 and figure 2 , the embodiment of the present invention includes:

[0021] A method for preventing and controlling gas during mining in a coal mining face, comprising several hydraulic supports 6 located at the coal mining face 3 close to the return airway 5, combined with figure 2 , the number of the hydraulic support 6 is 20-30, which includes a top beam 61, a cover beam 62 connected with the top beam 61, a tail beam 63 connected with the cover beam 62, a base 64, a support base 64 and a top beam 61 The column 65, the supporting base 64 and the front connecting rod 66 of the cover beam 62, as shown in the figure, the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com