High-precision low-cost electronic measurement system

An electronic measurement, low-cost technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of difficult popularization and popularization of high-precision electronic measurement systems, measurement accuracy, cost, volume and other parameter limitations, and achieve the goal of simplifying development difficulty and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

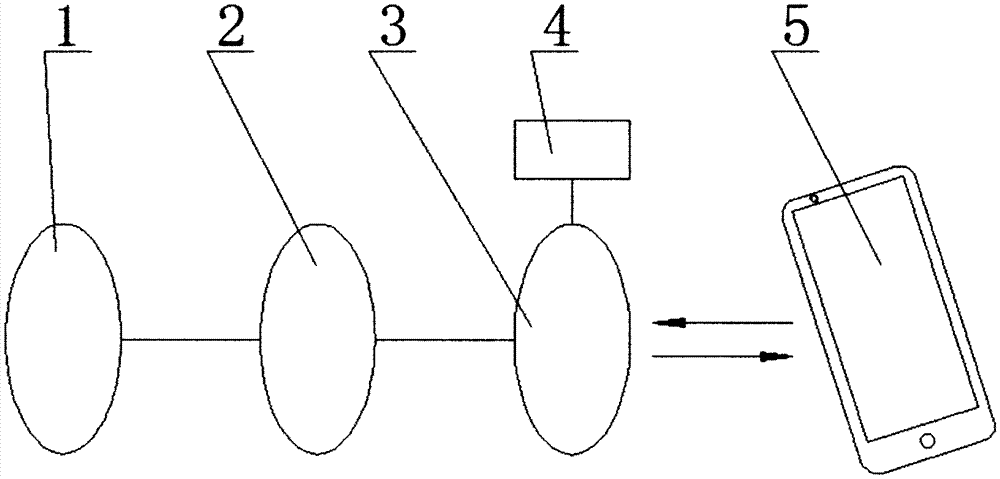

[0019] like figure 1 As shown, the sensor module 1 transmits the electrical signals measured by one or more sensors to the basic signal conditioning circuit 2 during measurement. After the basic signal conditioning circuit 2 performs basic amplification and conversion on the signal of the sensor module 1, the signal is sent to the basic data processing and communication module 3 for further sampling and preparation for transmission. At this time, the reason for simplifying and reducing the signal conditioning work of the basic signal conditioning circuit 2 as much as possible is because any sensor signal conditioning circuit will inevitably carry its own burden when it completes the amplification, shaping or conversion of the signal, or the main goal of filtering out specific noise. This is essentially to increase the number of variables in the system error in subsequent software operations. In addition to increasing hardware costs, it is also unfavorable for subsequent signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com