Pressure measuring equipment zeroing device for aero-engine test-bed and zeroing method

A technology for aero-engines and pressure measuring equipment, which is applied in measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of invalid operation, zero calibration data cannot be displayed and saved, and low efficiency, so as to increase the zero calibration efficiency and shorten the preparation. Time, save the disassembly process and the effect of the transportation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

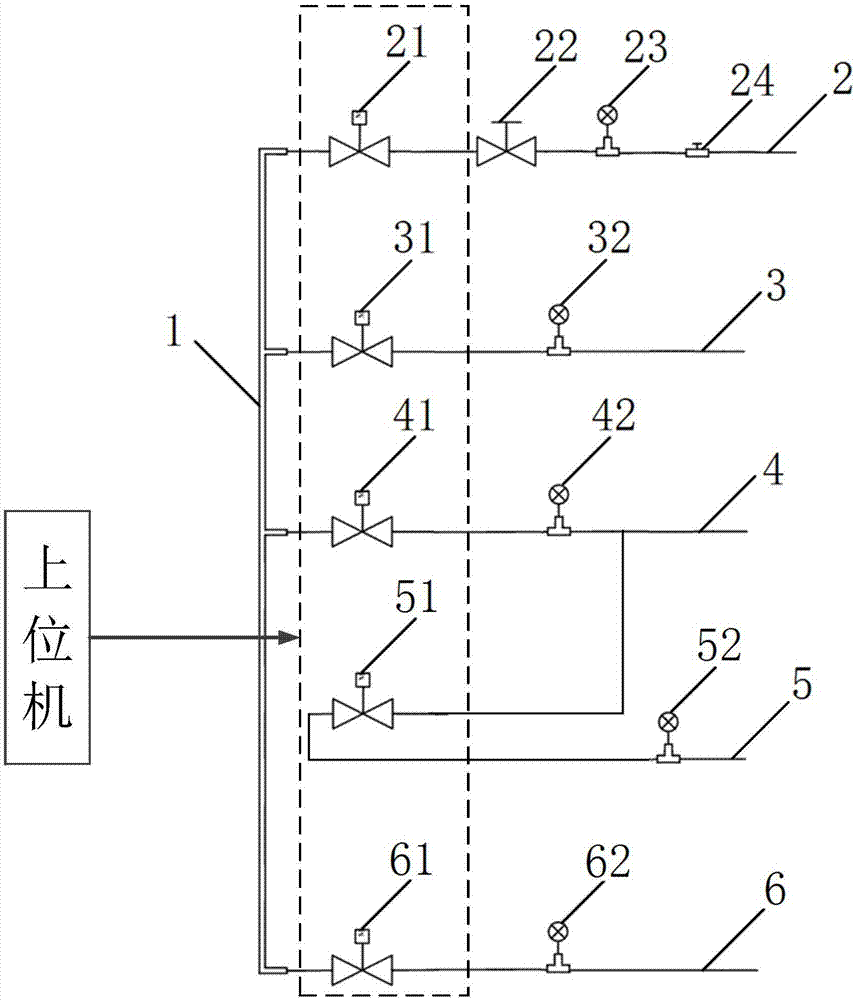

[0026] Such as figure 1 As shown, the zero calibration device for the pressure measurement equipment of the aero-engine test bench includes a mode switching pipeline 1 and a host computer. The pressure measurement equipment is provided with a zero calibration terminal, a first control terminal and a second control terminal. All the pressure measurement equipment The zero calibration terminals of all the pressure measuring devices are connected to each other to form a zero calibration common terminal, the first control terminals of all the pressure measuring equipment are connected to each other to form a first control common terminal, and the second control terminals of all the pressure measuring equipment The terminals are connected to each other to form a second control common terminal;

[0027] The mode switching pipeline 1 includes a mode intake pipeline 2, a first control pipeline 3, a second control pipeline 4, and an exhaust pipeline 6 that communicate with each other. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap