Quick-change type assembling tool for air conditioner air outlet port assembly of automobile

An automobile air conditioner and assembly assembly technology, which is applied in the direction of hand-held tools, manufacturing tools, workpiece clamping devices, etc., can solve the problems of labor consumption, cumbersome disassembly process, and impact on quality, so as to save the installation and disassembly process , the industrial effect is obvious, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

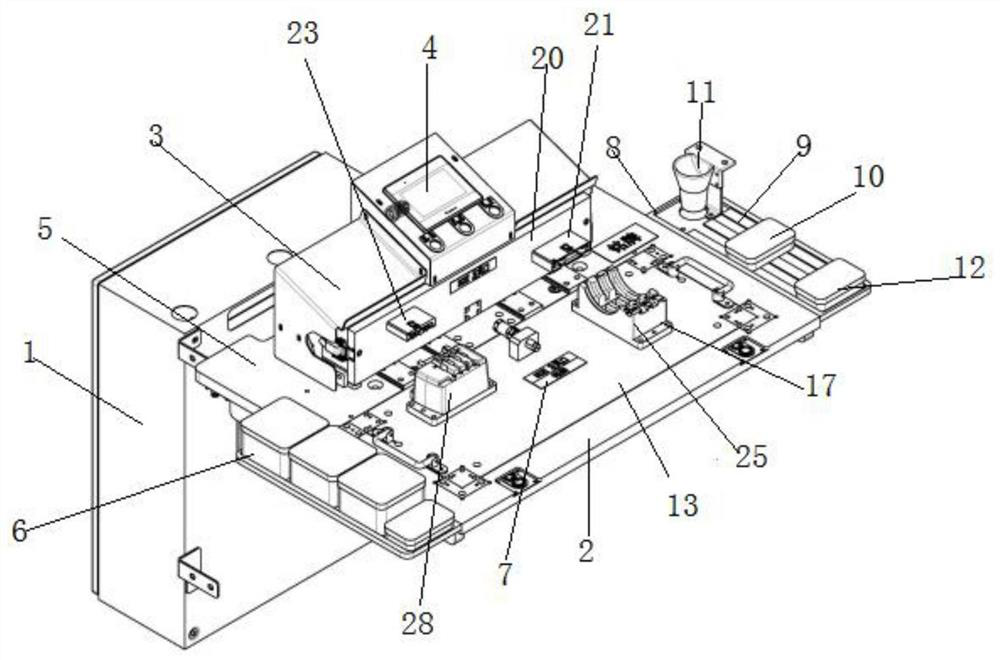

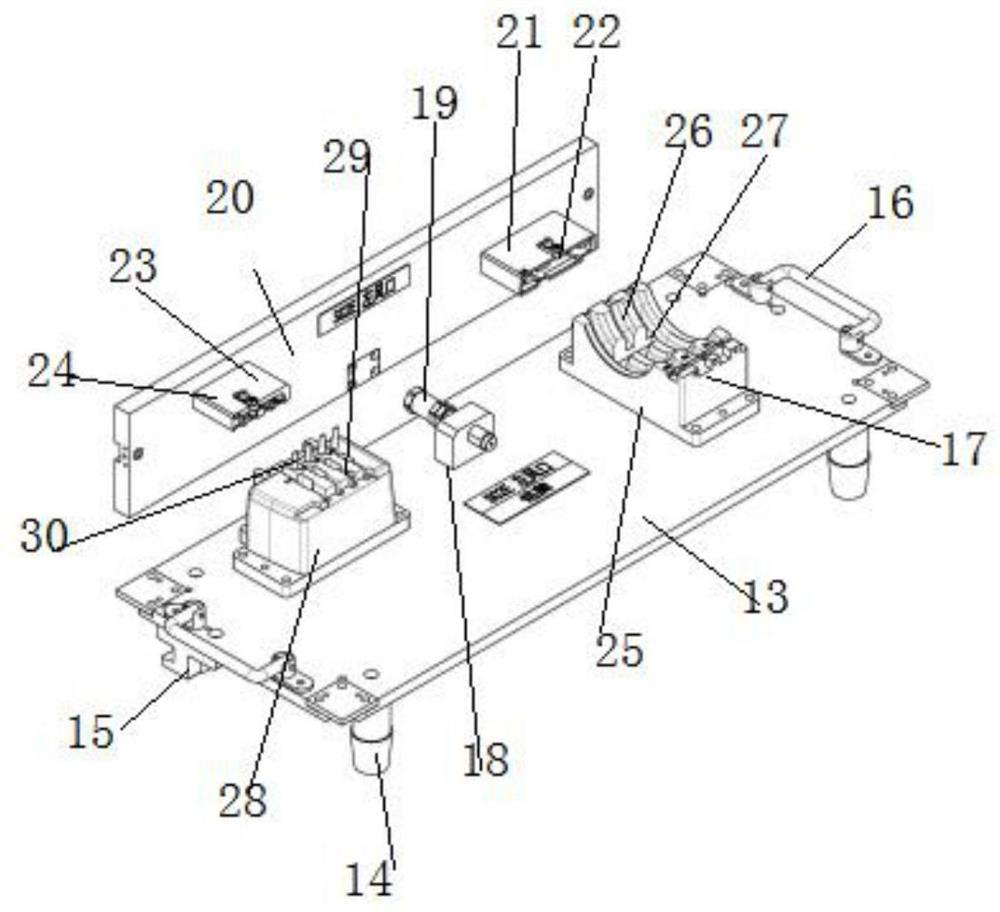

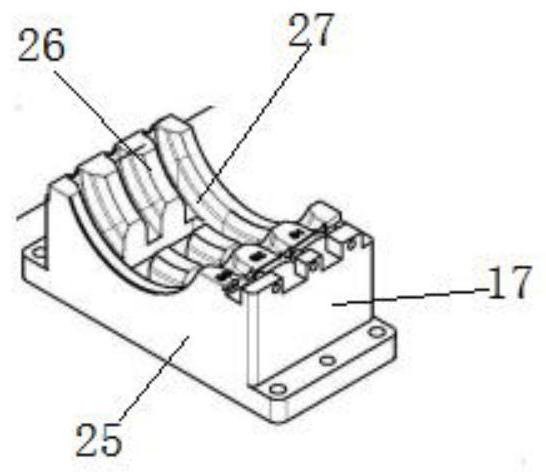

[0023] Example 1, such as Figure 1-4 As shown, a quick-change automobile air-conditioning air outlet assembly assembly tooling includes a tooling attachment base, a quick-change unit assembly connected to the tooling attachment base, and a PLC control box 1 connected to the side end of the tooling attachment base. , the tooling installation platform includes an installation table 2, a material box tray 3 located on the installation table 2, a man-machine interface 4 located on the material box tray 3, and an upper end of the installation table 2. The control cabinet body 5, the metal material storage box 6 located on the left side of the mounting table, the movable workpiece frame structure located on the right side of the mounting table, the quick change unit assembly includes a clamping seat provided on the mounting table 2 Platform 13, the assembly fixture seat structure of the air-conditioning air outlet on the clamping platform 13 and the lateral positioning structure of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap