Special equipment for detecting air tightness of new energy vehicle body battery pack

A special equipment and battery pack technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum, can solve the problems of poor sealing effect, affecting the performance of battery packs, and poor compaction performance, etc., achieving compact structure, The effect of high clamping degree and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

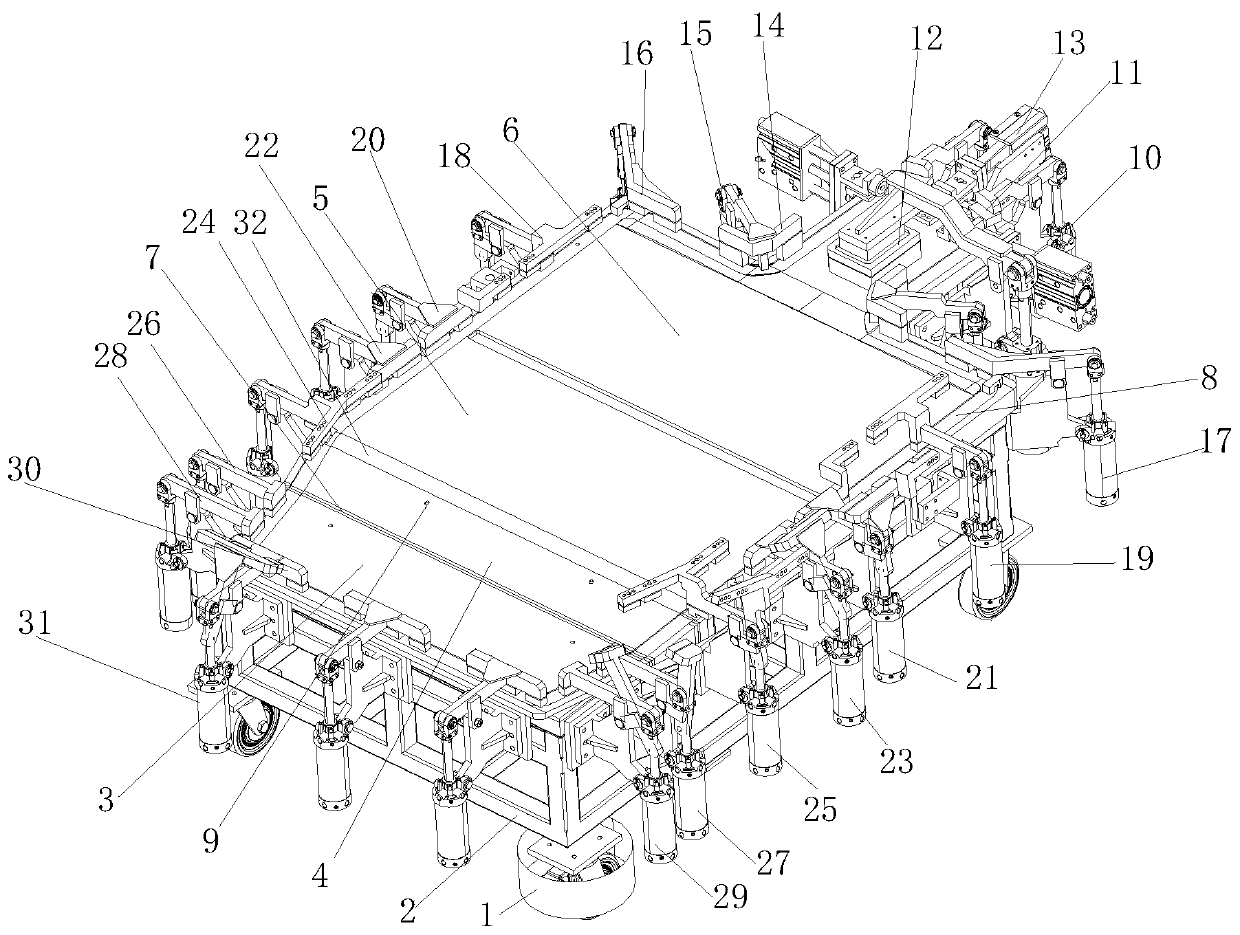

[0014] Example 1, such as figure 1 As shown, a new energy car body battery pack airtight performance testing equipment is characterized in that: the equipment includes a control base structure, a profiling table structure on the control base structure and a top press set around the profiling table structure. Tight seat structure, upper side end compression seat structure, lower side end compression seat structure, bottom end compression seat structure, the control base includes a base 1, a stepped inner platform body 2 arranged on the base, The profiled mesa structure includes a first step face body 3, a second step face body 4, a third step face body 5, a fourth step face body 6 and a first step face body arranged between the second step face body and the third step face body. Slope 7, the second slope 32 arranged between the third step surface and the fourth step surface, the outside of the first, second, third and fourth step surface is provided with a gasket 8, the first ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap