A Comprehensive Evaluation Method for Machining Performance of Materials

A technology of cutting processing and comprehensive evaluation, applied in the direction of program control, instrument, computer control, etc., can solve the problems of not reflecting the relationship between materials well, reflecting the lack of cutting performance, reliability and practicability of materials, etc., to achieve Concise and comprehensive evaluation analysis, rationalization of weights, and obvious effects of evaluation differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

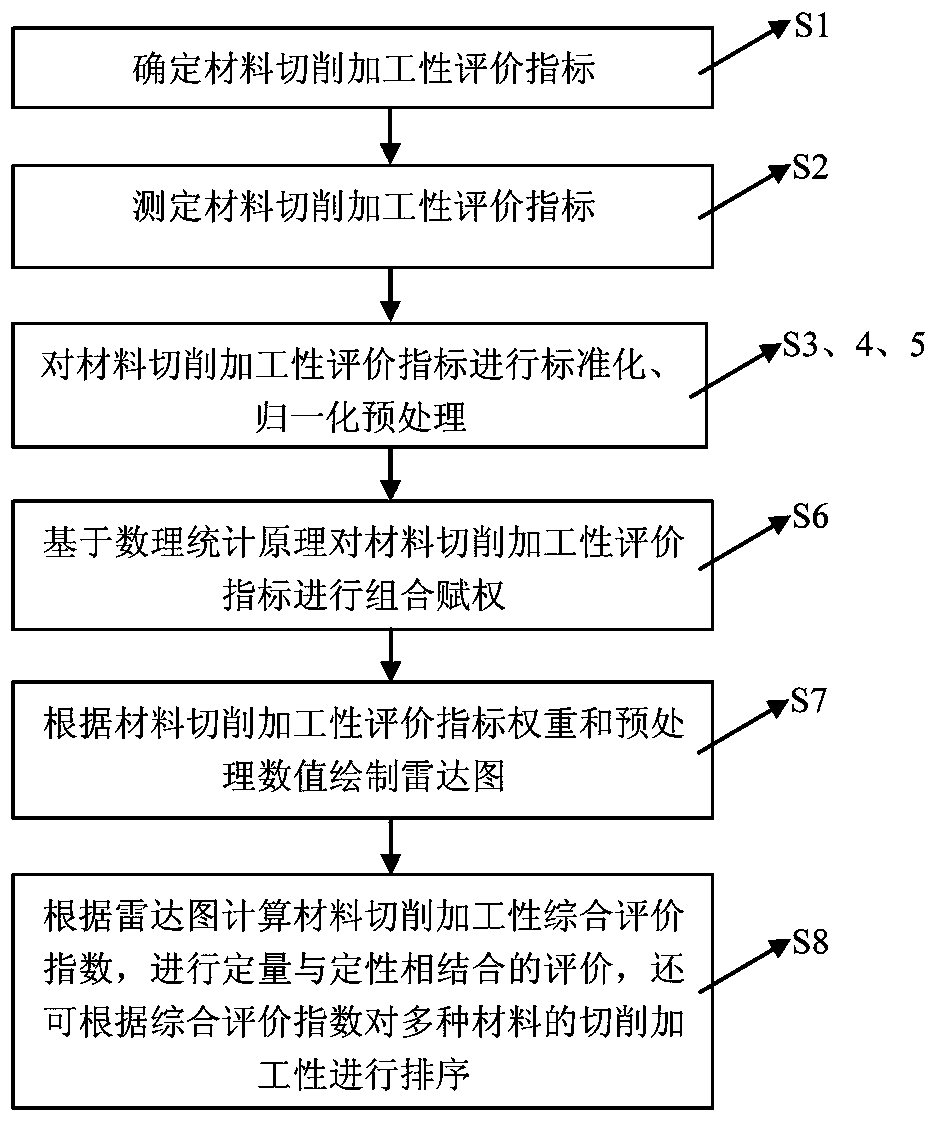

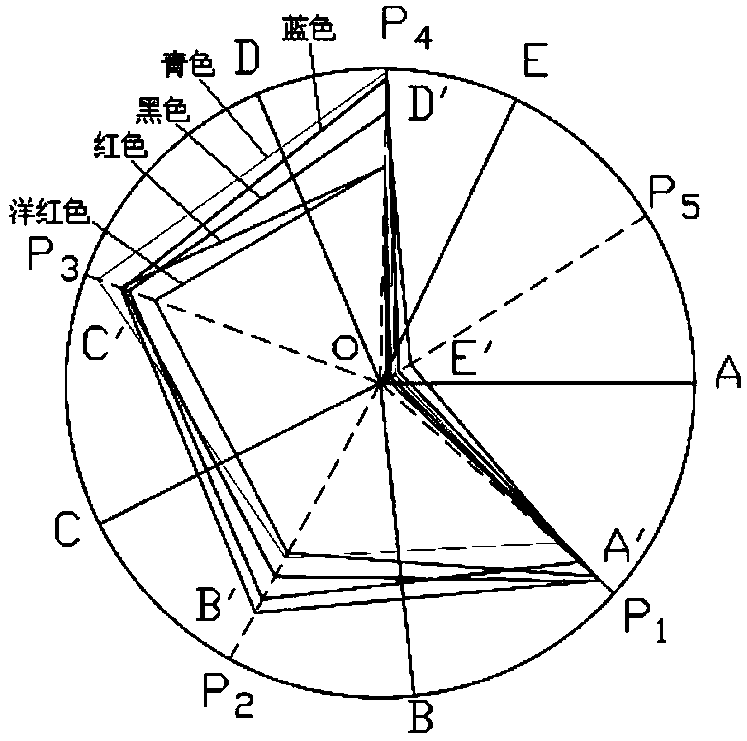

[0074] The invention is a comprehensive evaluation method for cutting performance of materials (engineering materials). see figure 1 Shown, the present invention comprises the following steps:

[0075] Step 1. Determine the evaluation index of the cutting performance of the evaluation object (i.e. the evaluation material of the present invention, the same below), these evaluation indexes are usually the most significant and widely used to the cutting performance of the evaluation object, including but not Limited to hardness, tensile strength σ b , elongation δ, impact toughness a k , thermal conductivity κ, etc.;

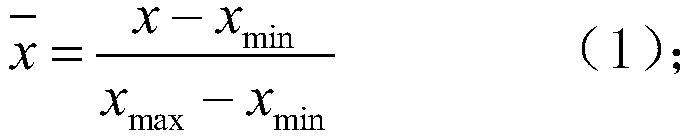

[0076] Step 2. According to the evaluation index determined for the evaluation object, measure the evaluation index of the cutting performance of the evaluation object, such as the tensile strength σ b and elongation δ are obtained by tensile test based on digital image correlation technology, thermal conductivity κ is measured by thermal conductivity test base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com