Orderly fruit putting system for slender melon picking robot

A picking robot and robot technology, which is applied in the field of agricultural robots, can solve the problems of difficulty in ensuring the ground height of the bottom of the fruit and the bottom of the box, the difficulty in effectively utilizing the space of the fruit box for efficient storage, the impact of the robot picking operation performance, and the like, so as to improve the efficiency of the fruit placing operation. , Improve work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

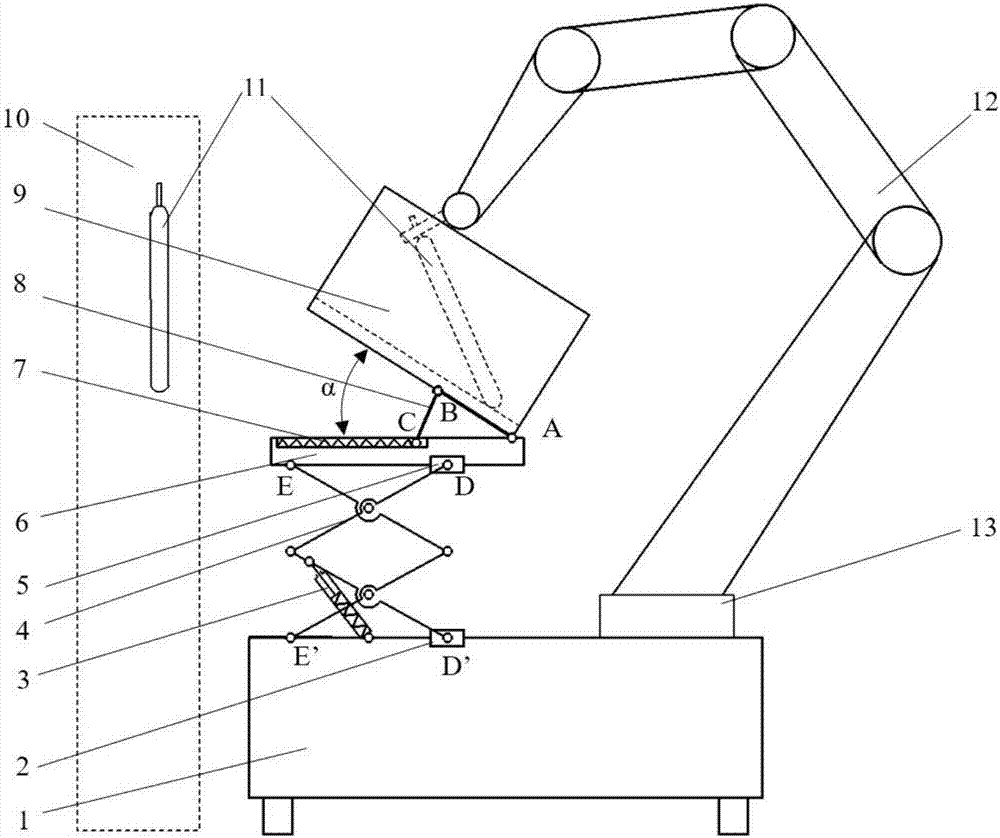

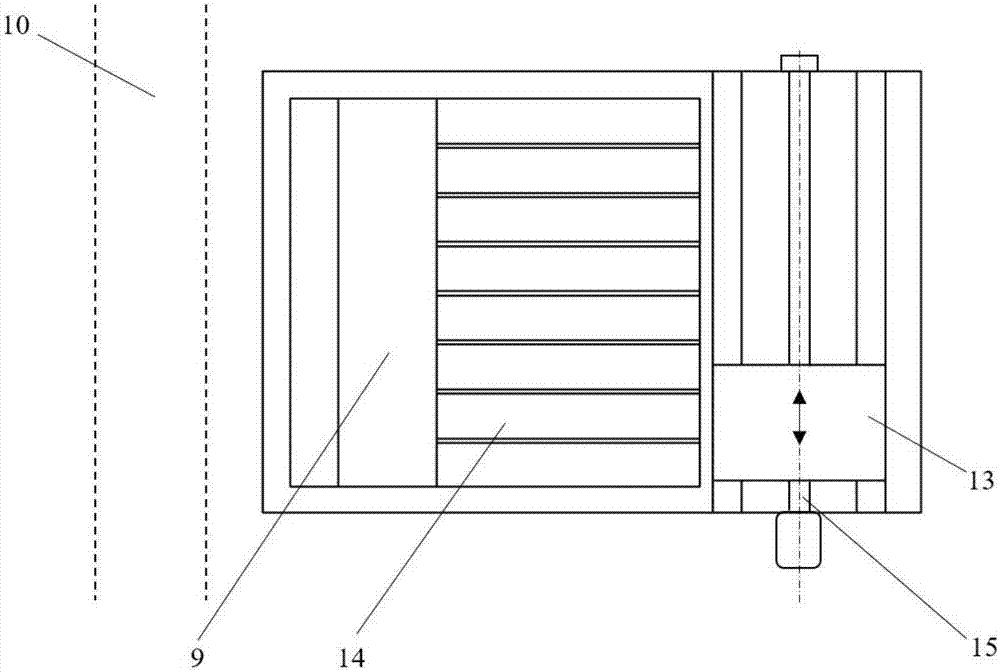

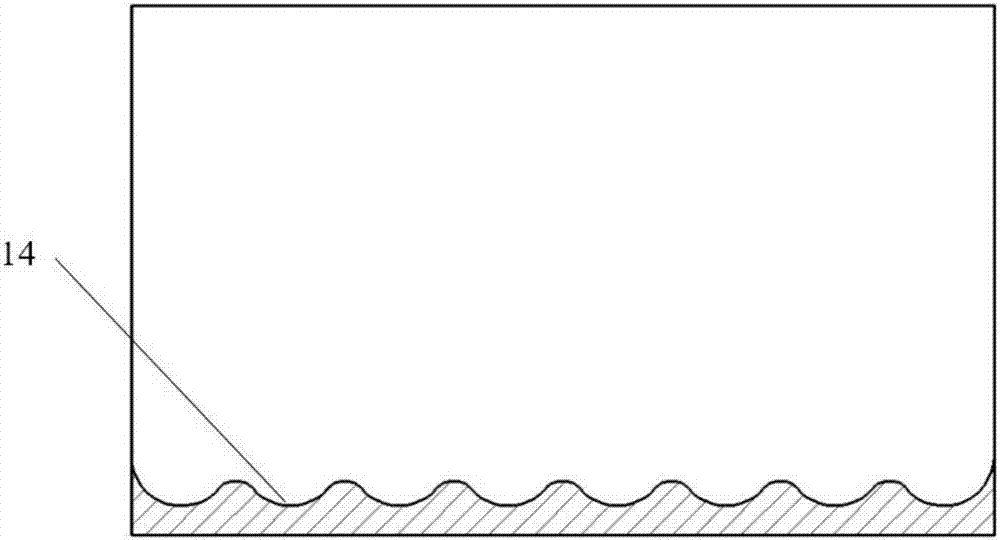

[0022] Such as figure 1 with figure 2 As shown, the patented slender melon picking robot orderly fruit release system is composed of a fruit box pliable tilting mechanism, a compliant lifting mechanism and a manipulator translation mechanism. The compliant lifting mechanism and the manipulator translation mechanism are installed on the robot mobile platform 1, and the compliant and tilting mechanism of the fruit box is installed above the compliant lifting mechanism. The fruit box compliant roll mechanism is installed above the compliant lifting mechanism and arranged on the side of the robot mobile platform 1 close to the picking area 10, and the manipulator translation mechanism is arranged on the robot mobile platform 1 away from the side of the picking area 10.

[0023] Wherein the fruit box pliable ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com