Yogurt and preparation method thereof

A technology of yogurt and hydroxypropyl distarch phosphate, which is applied in the directions of milk preparations, dairy products, and applications, can solve the problems of yogurt that needs to be improved, and achieve the effects of rich nutritional components, strong stability and high protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

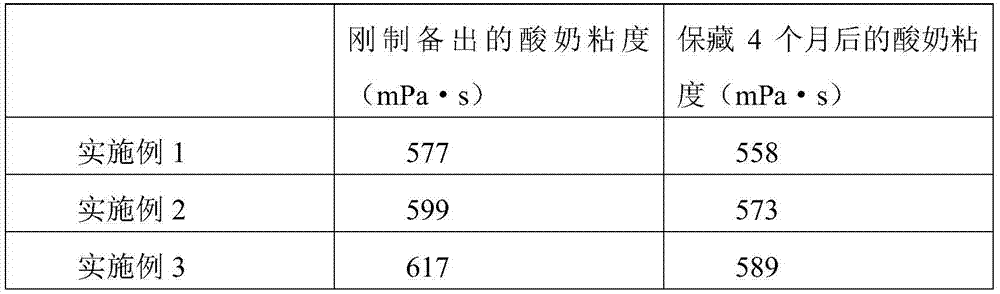

Embodiment 1

[0050] In this example, yogurt was prepared as follows:

[0051] (1) the white granulated sugar of 7.5 parts by weight, the hydroxypropyl distarch phosphate of 0.3 parts by weight, the agar of 0.08 parts by weight, the low methoxy pectin of 0.15 parts by weight, the diacetyl tartaric acid mono-diglycerol of 0.055 parts by weight The ester is mixed with 0.01 parts by weight of gellan gum, and the mixed material is mixed with 0.3 parts by weight of cream.

[0052] (2) In the batching tank, when the milk of 91 parts by weight is warming up to 45 degrees Celsius, start to inhale the mixture obtained in step (1) in the batching tank, and stir the ingredients at 60 degrees Celsius for 15 minutes. Then carry out homogenization treatment, primary pressure 120bar, secondary pressure 60bar, carry out sterilizing treatment after homogenization, sterilizing temperature is 110 degrees centigrade, time is 3 seconds, sterilized product is cooled to 42 degrees centigrade and starter is added,...

Embodiment 2

[0055] In this example, yogurt was prepared as follows:

[0056](1) the white granulated sugar of 8.0 weight parts, the hydroxypropyl distarch phosphate of 0.4 weight parts, the agar of 0.12 weight parts, the low methoxy pectin of 0.17 weight parts, the diacetyl tartaric acid mono-diglycerol of 0.059 weight parts Ester and 0.03 parts by weight of gellan gum are mixed, and the mixed material is mixed with 0.38 parts by weight of cream.

[0057] (2) In the batching tank, when the milk of 90.841 parts by weight is warming up to 45 degrees Celsius, start to inhale the mixture obtained in step (1) in the batching tank, and stir the ingredients at 60 degrees Celsius for 15 minutes. Carry out homogeneous treatment then, primary pressure 130bar, secondary pressure 70bar, carry out sterilization after homogeneous, sterilization temperature is 110 degrees centigrade, time is 3 seconds, and sterilized product is cooled to 42 degrees centigrade to add starter, ferment in fermentation tank...

Embodiment 3

[0060] In this example, yogurt was prepared as follows:

[0061] (1) the white granulated sugar of 8.5 parts by weight, the hydroxypropyl distarch phosphate of 0.5 parts by weight, the agar of 0.17 parts by weight, the low methoxy pectin of 0.22 parts by weight, the diacetyl tartaric acid mono-diglycerol of 0.067 parts by weight The ester was mixed with 0.04 parts by weight of gellan gum, and the mixed material was mixed with 0.48 parts by weight of cream.

[0062] (2) In the batching tank, when the milk of 90.023 parts by weight is warming up to 45 degrees Celsius, start to inhale the mixture obtained in step (1) in the batching tank, and stir the ingredients at 60 degrees Celsius for 15 minutes. Then carry out homogenization treatment, primary pressure 140bar, secondary pressure 80bar, carry out sterilizing treatment after homogenization, sterilizing temperature is 110 degrees centigrade, time is 3 seconds, sterilizing treatment product is cooled to 42 degrees centigrade, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com