Stirring device

A switch device and workbench technology, which is applied in the field of mixing equipment, can solve problems such as unevenness, time-consuming and labor-consuming, and low efficiency, and achieve the effects of improving work efficiency, reducing labor intensity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

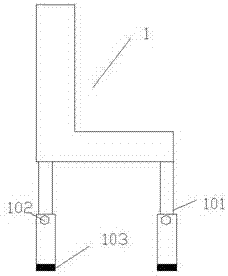

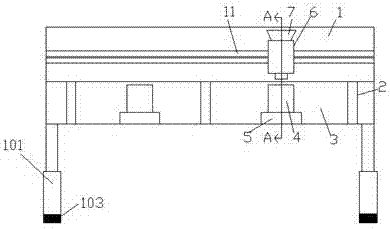

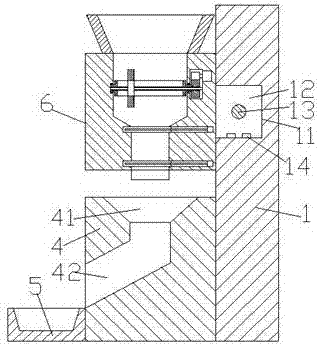

[0022] Such as Figure 1-Figure 4 As shown, a stirring device of the present invention includes a workbench 1, and the four corners of the bottom of the workbench 1 are provided with lifting rods 101, and the middle end of the left end surface of the lifting rod 101 is provided with a tightening member 102. , the bottom of the lifting rod 101 is provided with an anti-skid pad 103, and the height of the lifting rod 101 can be adjusted according to the height of the operator through the tightening member 102, so as to achieve an ideal working height and make the operation more labor-saving. The anti-slip mat 103 can effectively prevent the lifting rod 101 from slipping when it is supported due to the wet and slippery ground, and improves the stability when it is supported. Groove 11, in the sliding groove 11, a guide block 12 is slidably connected, and the front end surface of the guide block 12 is fixedly provided with a container 6, and the top of the container 6 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com