A fast cargo loading and unloading mechanism for logistics vehicles

A technology for loading and unloading mechanisms and logistics vehicles, which is applied to vehicles with wheels, vehicles with elevated loading platforms, etc., can solve the problems of difficulty in moving goods, lower work efficiency, and greater physical effort, so as to facilitate the loading and unloading of goods, The effect of reducing work intensity and reducing the difficulty of loading and unloading goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

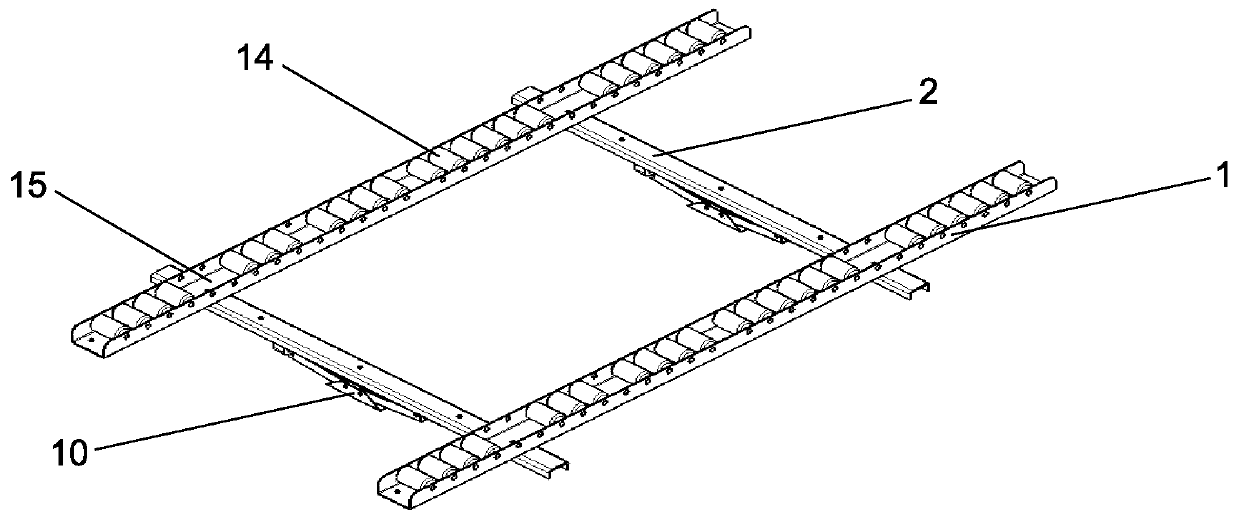

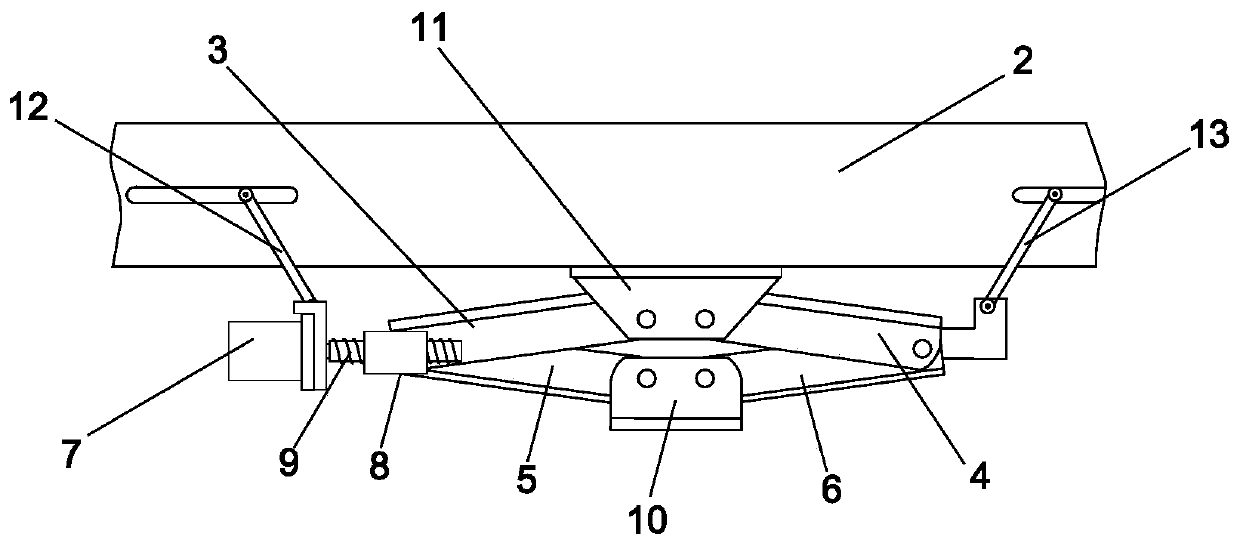

[0020] Such as figure 1 , figure 2 As shown, a cargo fast loading and unloading mechanism of a logistics vehicle is located on the logistics vehicle compartment. The cargo rapid loading and unloading mechanism of the logistics vehicle includes two cargo brackets 1, two supporting beams 2 and an adjustable cargo bracket 1 position height electric lifting device, cargo bracket 1 and support beam 2 intersect to form a "well" shape, each cargo bracket 1 is provided with a channel 15, and a row of rolling parts is arranged in the channel 15 14. The rolling elements 14 are rollers, and there are 23 rollers in each row. The two ends of the rotating shafts of the rollers are rotatably connected to the groove wall of the through groove 15, and the axes of each roller are parallel. The cargo bracket 1 is connected to the support beam 2, the electric lifting device is fixed on the compartment of the logistics vehicle, and the support beam 2 is fixedly connected to the electric lifting ...

Embodiment 2

[0023] There are three supporting beams 2, and the rolling parts 14 are rolling balls. There are 25 through holes on the cargo bracket 1, each of which is tightly equipped with a plastic rolling ball cage, and the rolling ball cage surrounds and rolls. The spherical surface of the component 14 is adapted to the cavity. The cavity is drum-shaped, and the middle part of the rolling ball is rotatably embedded in the cavity. The upper and lower ends of the rolling ball respectively expose a section of the ball crown outside the rolling ball cage. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com