A kind of polymer-based asphalt anti-stripping agent and its preparation method and application

An anti-stripping agent and polymer technology, applied in the field of new materials, can solve the problems of complex asphalt concrete construction process, prolonged mixing time, and increased construction difficulty, so as to increase construction difficulty, reduce separation links, and reduce preparation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

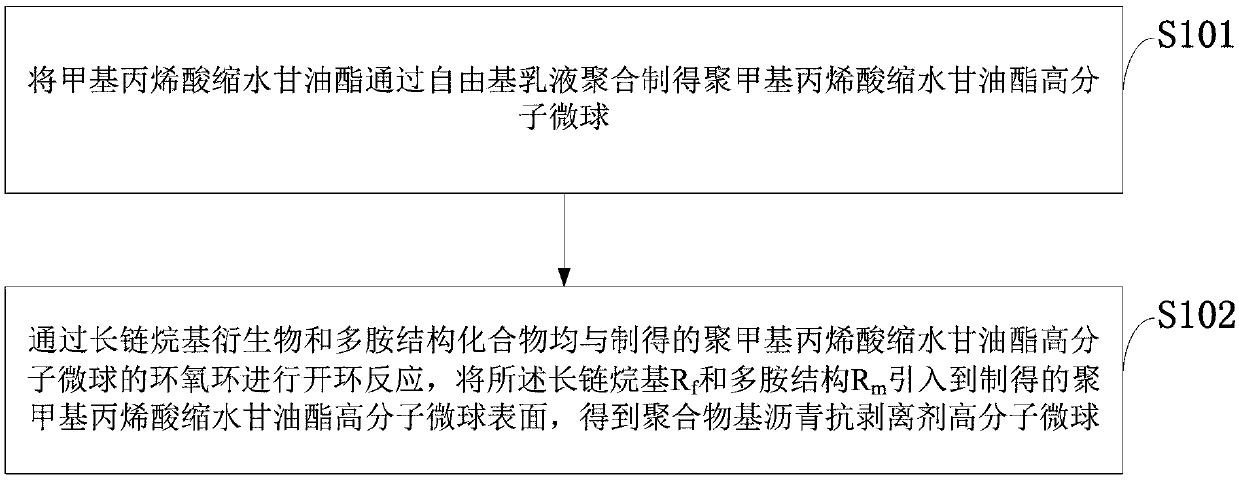

[0026] Such as figure 1 As shown, the preparation method of the polymer-based asphalt anti-stripping agent provided by the embodiments of the present invention comprises the following steps:

[0027] S101: Polyglycidyl methacrylate macromolecule microspheres are prepared by radical emulsion polymerization of glycidyl methacrylate;

[0028] S102: Through the ring-opening reaction between the long-chain alkyl derivatives and the polyamine structure compound and the epoxy ring of the prepared polyglycidyl methacrylate polymer microspheres, the long-chain alkyl R f and the polyamine structure R m introduced into the surface of the prepared polyglycidyl methacrylate macromolecular microspheres to obtain the polymer-based asphalt anti-stripping agent macromolecular microspheres.

[0029] Embodiments of the present invention also provide an application of the polymer-based asphalt anti-stripping agent as described above, comprising the following steps:

[0030] The above-mentioned...

Embodiment 1

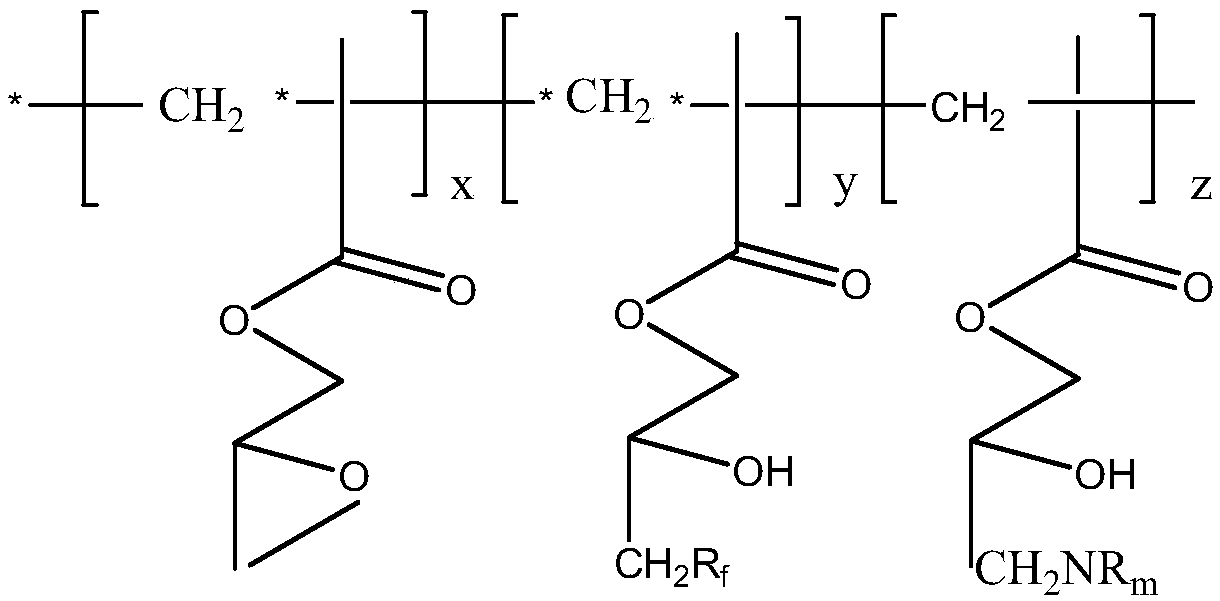

[0033] The polymer-based asphalt anti-stripping agent of the embodiment of the present invention has the following general formula:

[0034]

[0035] Wherein, x is an integer of 10-500, y is an integer of 10-500, and z is an integer of 10-500;

[0036] R f Dodecyl mercaptan above C6, R m The polyamine chain is triethylenetetramine.

[0037] The preparation method of the polymer-based asphalt anti-stripping agent of the embodiment of the present invention comprises the following steps:

[0038] 1) Add 100ml aqueous solution containing 5% (wt %) span-80 emulsifier in the four-necked flask that condensing tube, nitrogen inlet and outlet, mechanical stirring device are housed, stabilizer PVP-k30 (povidone) 3g, after dissolving Add monomers (GMA (glycidyl methacrylate) 30g, BA (butyl acetate) 3g, divinylbenzene 2g and initiator AIBN (azobisisobutyronitrile) 0.6g, stir with nitrogen for 30min, 70°C Constant temperature, 120r / min stirring 24h, after cooling, make PGMA (polygly...

Embodiment 2

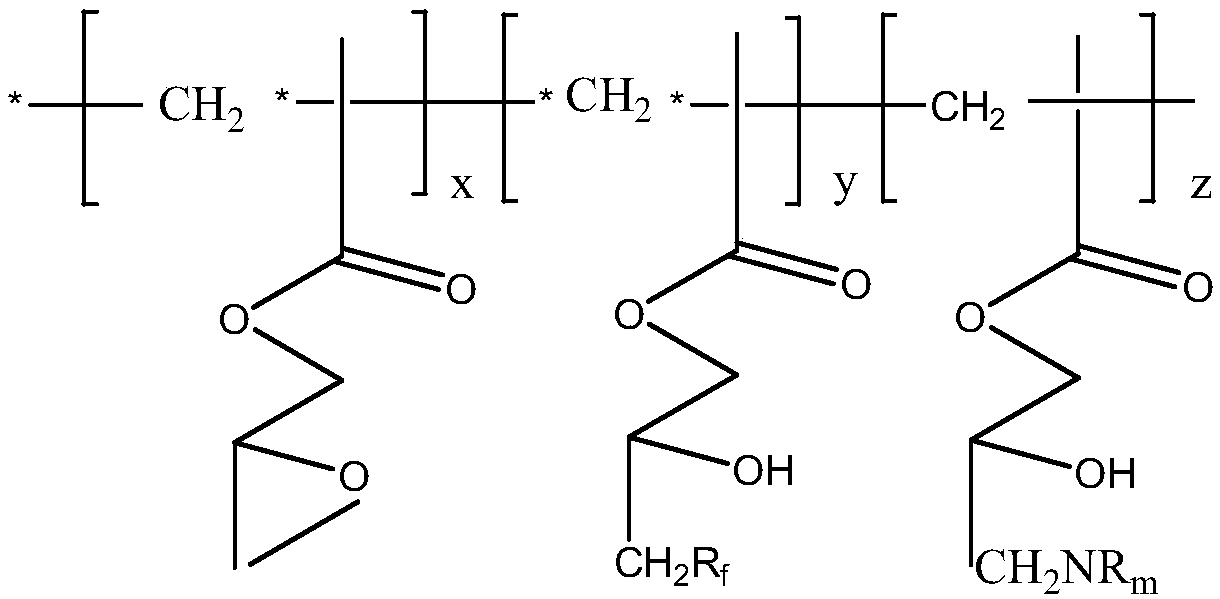

[0042] The polymer-based asphalt anti-stripping agent of the embodiment of the present invention has the following general formula:

[0043]

[0044] Wherein, x is an integer of 10-500, y is an integer of 10-500, and z is an integer of 10-500;

[0045] R f is octadecanoic acid, R m The polyamine chain is hexamethylenediamine.

[0046]1) add the 100ml aqueous solution that contains 5% (wt%) tween-60 emulsifier in the four-neck flask that condenser pipe, nitrogen inlet and outlet, mechanical stirring device are housed, stabilizing agent PVA (Povidone) 3g, after dissolving, add single Body (GMA (glycidyl methacrylate) 30g, HPMAS (sodium methacrylate hydroxypropyl sulfonate) 5g, pentaerythritol tripropylene 1g and initiator AIBN (azobisisobutyronitrile) 0.3g, nitrogen gas was stirred for 30min , constant temperature at 70°C, stirring at 120r / min for 24h, after cooling, a PGMA (polyglycidyl methacrylate) polymer microsphere emulsion was prepared;

[0047] 2) Add 8.0 g of oct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com