Engineering driving vehicle and paver

A technology for driving vehicles and slip-form paver, applied in the direction of roads, road repair, roads, etc., can solve the problems of only special vehicles, prolong the construction period, inconvenient construction scheduling, etc., to improve the utilization rate, improve the construction efficiency, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

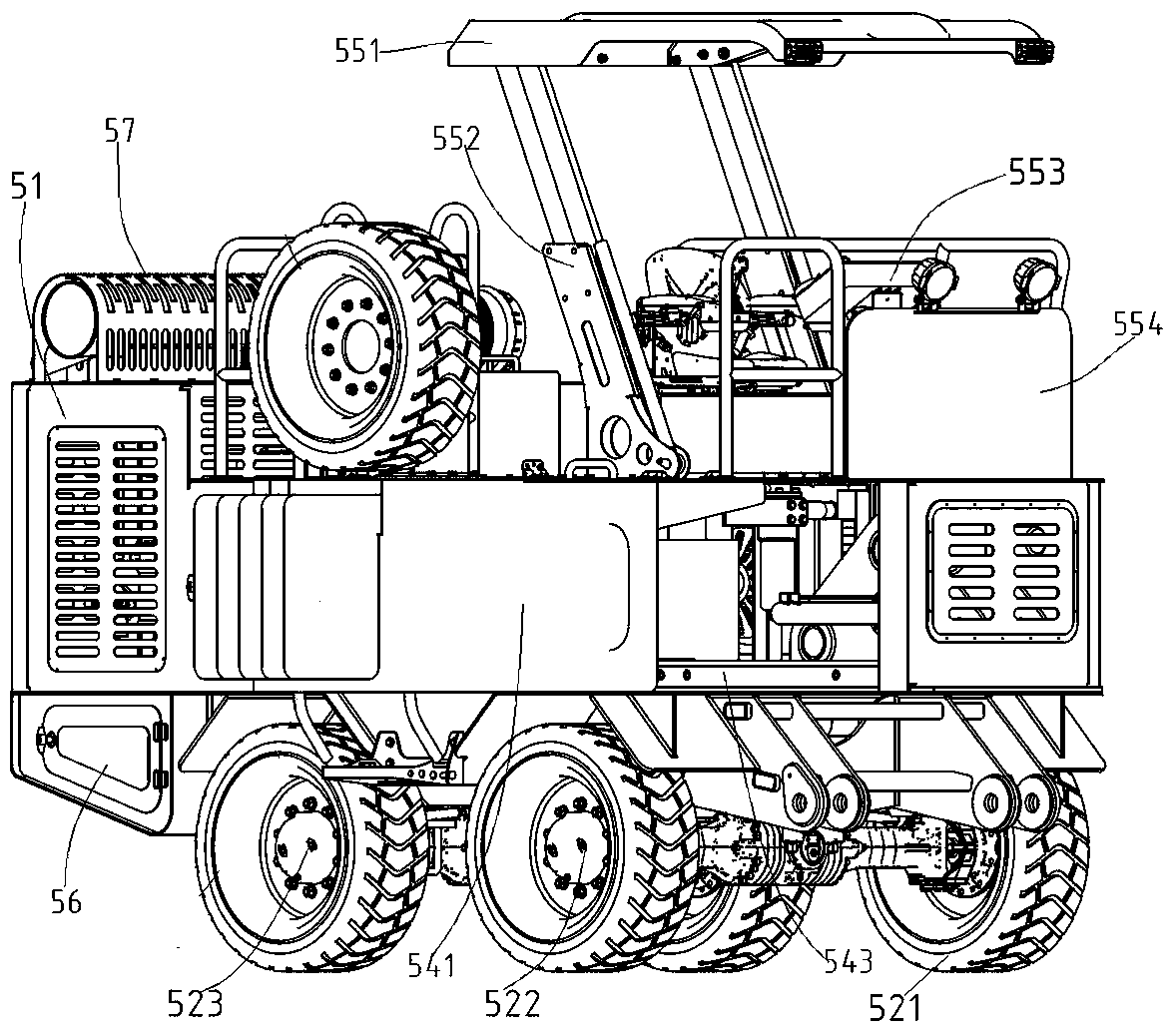

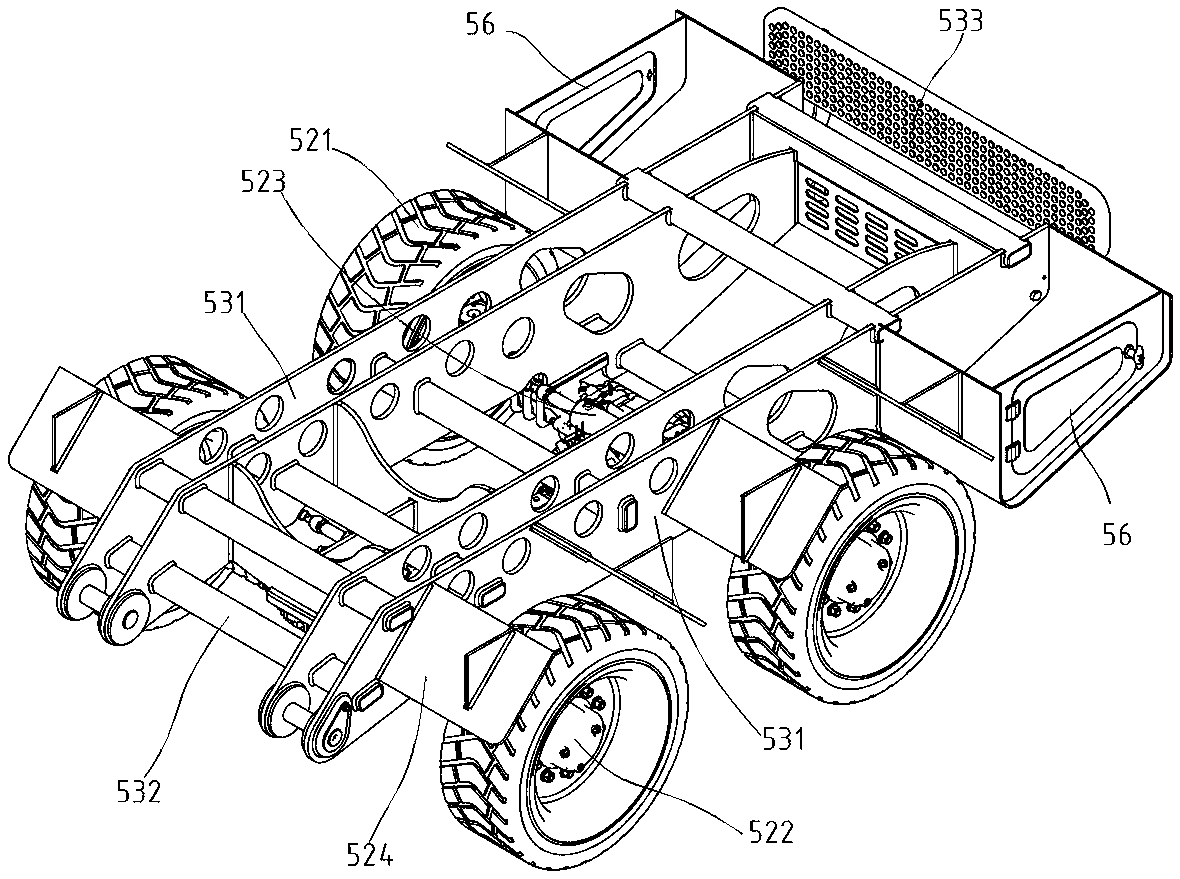

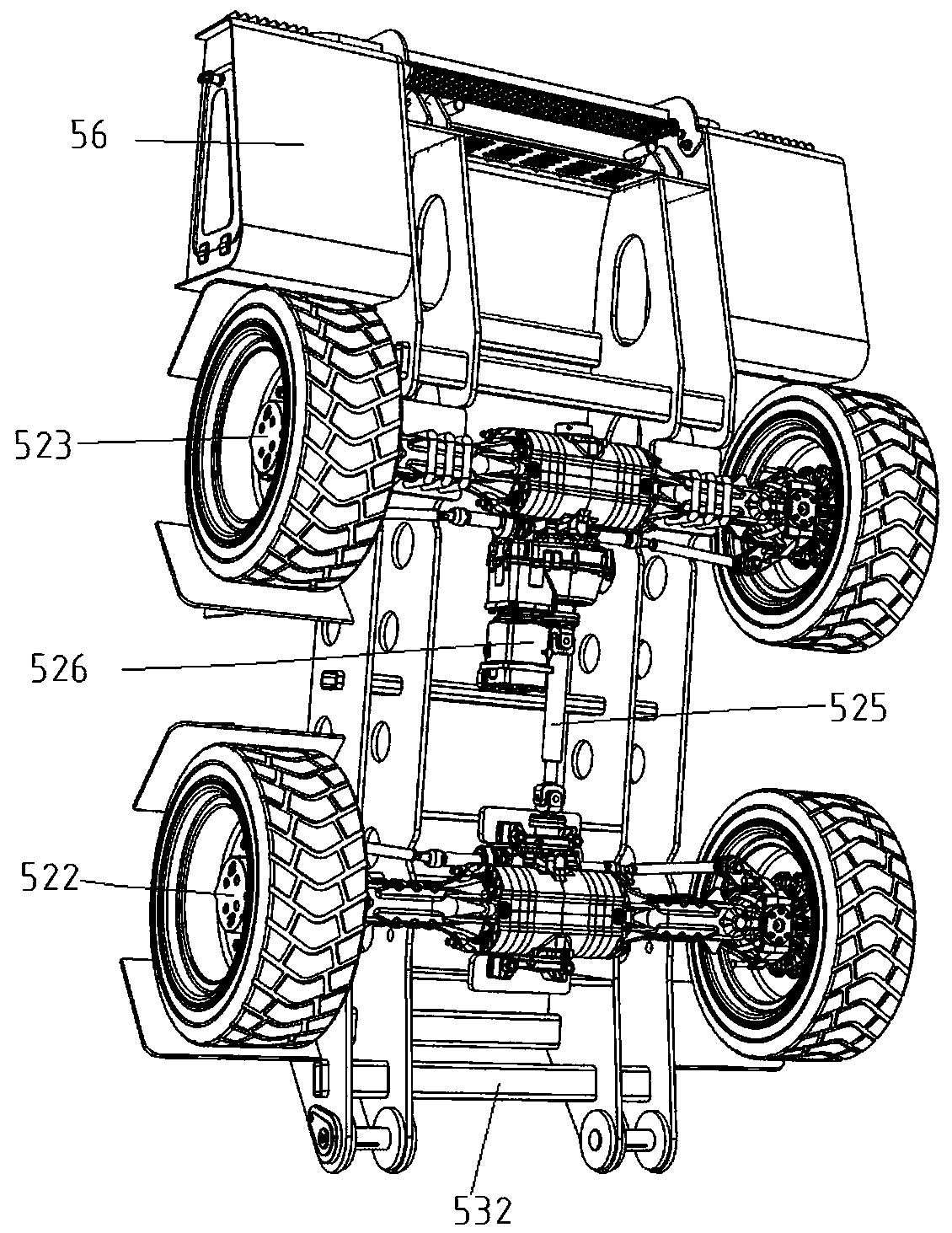

[0039] An engineering driving vehicle, including a driving host 5 that can provide walking power, the driving host 5 includes a host chassis 53; the host chassis 53 includes several side beams 531 arranged in parallel in the longitudinal direction and several connecting beams arranged in parallel in the transverse direction 532, the board surface of the side beams 531 is perpendicular to the horizontal plane, and the connecting beams 532 are respectively pierced on several of the side beams 531.

[0040] For the above-mentioned engineering driving vehicle, the several side beams 531 are divided into two groups arranged left and right and each group includes 1-3 side beams 531;

[0041] The chassis front axle 522 and the chassis rear axle 523 are arranged below the main engine chassis 53, the chassis rear axle 523 is connected with a drive assembly 526, and the transmission shaft 525 is connected between the chassis front axle 522 and the chassis rear axle 523. The chassis rear...

Embodiment 2

[0054] Compared with Embodiment 1, this implementation adopts the form of rotating counterweight, and the counterweight box 541 rotates relative to the driving host 5 to realize the counterweight. Compared with the telescopic counterweight form of Embodiment 1, the structure is simpler, and the operation is relatively stable and the vibration is small.

Embodiment 3

[0056] Compared with Embodiment 1, this embodiment adopts the form of cab 556, which is foldable and closed, and can play the role of wind and sand in harsh environments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com