Weft yarn measuring and storing device of loom

一种纬纱测长、储纱的技术,应用在织机、纺织、纺织品和造纸等方向,能够解决橡胶寿命降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

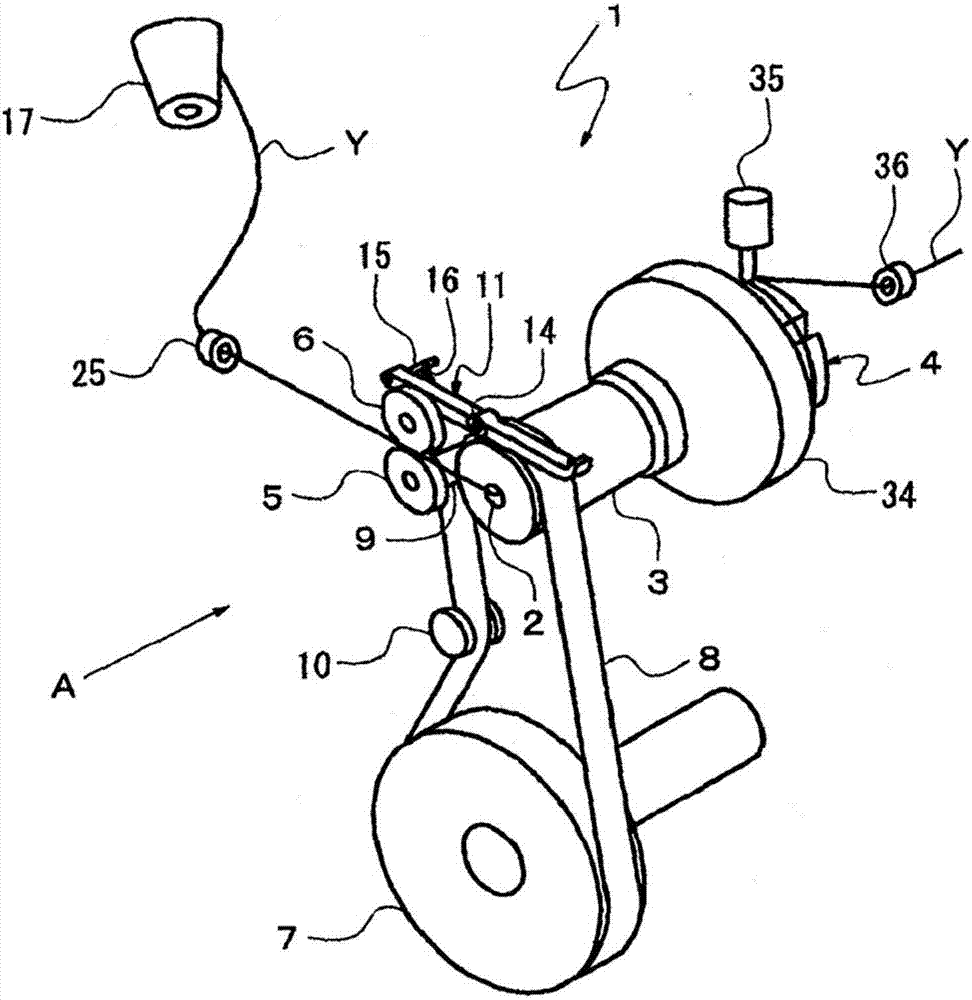

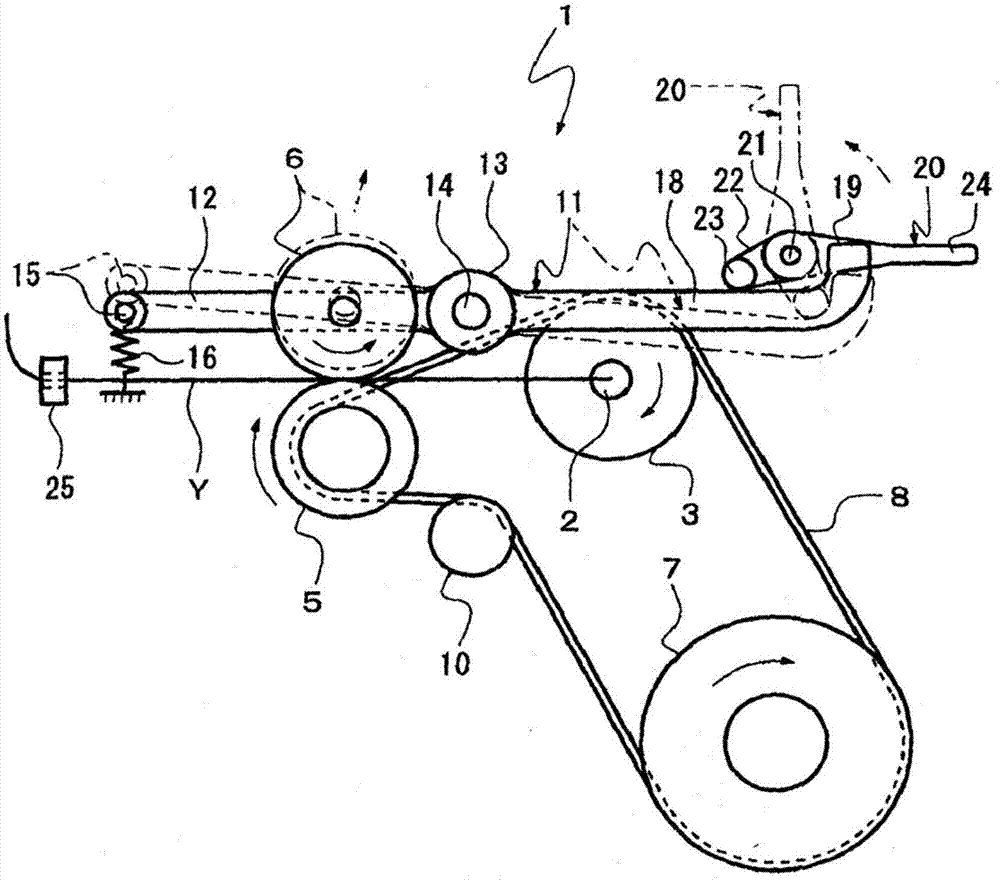

[0023] based on Figure 1 ~ Figure 3 The first embodiment will be described. exist figure 1 as well as figure 2 Among them, the weft yarn length measuring and storage device 1 provided on the loom has: a rotating shaft 3 having a weft yarn introduction port 2; a yarn storage cylinder 4 which is held on the front end side of the rotating shaft 3 in a stationary state; and a driving roller 5 and The feed rollers 6 are arranged parallel to the rotation shaft 3 . A pulley 7 is arranged below the rotating shaft 3, and the pulley 7 is connected to a main shaft (not shown) of the loom or a dedicated electric motor (not shown) to rotate.

[0024] The driving belt 8 wound around the pulley 7 is wound around the rotating shaft 3 , the shaft 9 of the driving roller 5 , and the guide roller 10 . The driving belt 8 can be constituted by a timing belt, a flat belt, or the like. When the pulley 7 rotates, the rotating shaft 3 and the driving roller 5 are rotated by the driving belt 8 ,...

no. 2 Embodiment approach

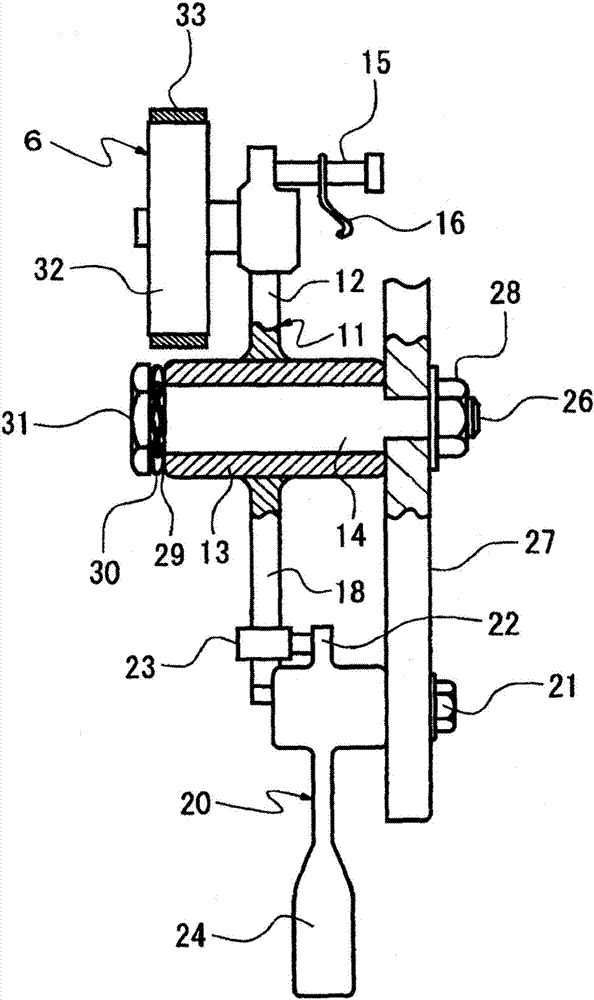

[0038] Figure 4 The second embodiment is shown, and the same configurations as those of the first embodiment will be described using the same reference numerals, and detailed description will be omitted. In the second embodiment, the frictional resistance applying portion is constituted by the coil spring 37 which is an elastic member. The coil spring 37 is fitted to the support shaft 14 protruding toward the end surface 29 side of the protruding portion 13 of the support rod 11 . After the coil spring 37 is fitted in the support shaft 14 , it is crimped to the end surface 29 of the protrusion 13 by fastening with the bolt 31 .

[0039] In the second embodiment, since the frictional resistance is added to the end surface 29 of the protrusion 13 by the spring force of the coil spring 37 interposed between the support rod 11 and the bolt 31, frictional resistance against the spring force of the spring 16 can be absorbed. The upward pressing force of the feed roller 6 suppress...

no. 3 Embodiment approach

[0041] Figure 5 3rd Embodiment is shown, and the same structure as 1st Embodiment is demonstrated using the same code|symbol, and detailed description is abbreviate|omitted. In the third embodiment, a frictional resistance applying portion is constituted by a cylindrical member 38 fixed to an outer peripheral surface 39 of a support shaft 14 . The cylindrical member 38 is fitted and fixed to the outer peripheral surface 39 of the support shaft 14 which is a contact portion with the support rod 11 . The outer periphery of the cylindrical member 38 is roughened so that the frictional resistance is increased by using processing techniques such as plating, shot peening, and shot peening.

[0042] The inner peripheral surface 40 of the protruding portion 13 of the support rod 11 , which is a contact portion with the support shaft 14 , is rotatably fitted to the cylindrical member 38 of the support shaft 14 , and is integrated with the support shaft 14 by fastening with the bolt 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com