Core-taking system for automatic segmented deslagging and rock core truncation and using method thereof

An automatic segmentation and core technology, which is applied in earthwork drilling, undisturbed core extraction devices, wellbore/well components, etc., can solve the problems of core remaining inside the drill hole, drill sticking, serious problems, etc., to overcome coal Rock slag and core cannot be cut off, the application is safe and reliable, and the application is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

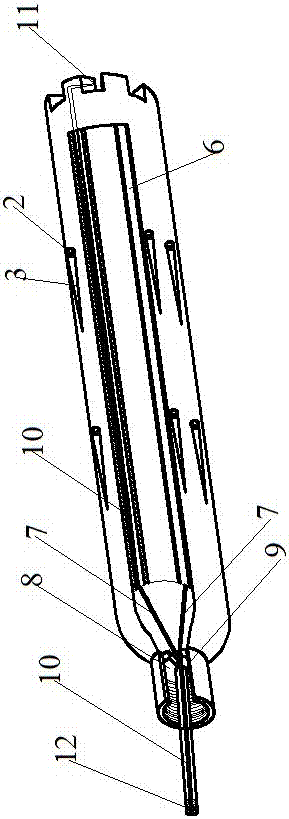

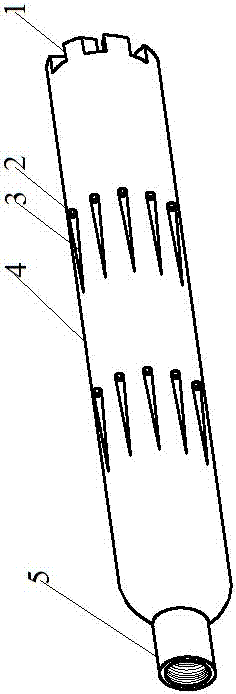

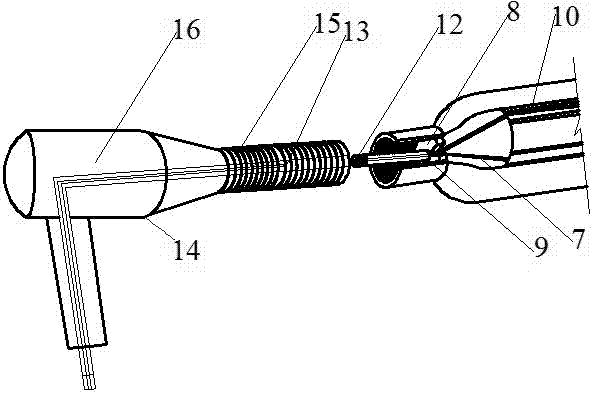

[0042] like figure 1 As shown, the core pipe 4 includes two rows of drainage holes 2 and six cutting teeth 1, the two rows of drainage holes 2 divide the pipe body into three equal parts, and the six cutting teeth 1 are located on the circumference of the pipe body. point; the middle of the core tube 4 is provided with a section of hollow part, that is, the low-pressure water chamber 6; the tail end of the core tube 4 is the connection end with the special drilling rig 16 head, and is provided with an internal thread, which can make the low pressure The water pipe 9 passes through the high-pressure water pipe 10, and the internal thread is used to connect with the machine head connection end 15 of the drilling rig.

[0043] One of the six cutting teeth 1 is provided with a high-pressure water cutting hole 11 , and the high-pressure water cutting hole 11 communicates with the low-pressure water chamber 6 .

[0044] The connecting end 15 of the head of the special drilling rig ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com