Air exhauster adopting vacuum pipe for driving and conical sleeve pipe for accelerating

A vacuum tube and exhaust fan technology, applied in the field of solar energy, can solve the problems of limited application occasions and methods, insufficient ventilation intensity, etc., and achieve the effects of simple and safe operation and maintenance, no energy consumption and environmental costs, and simple processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

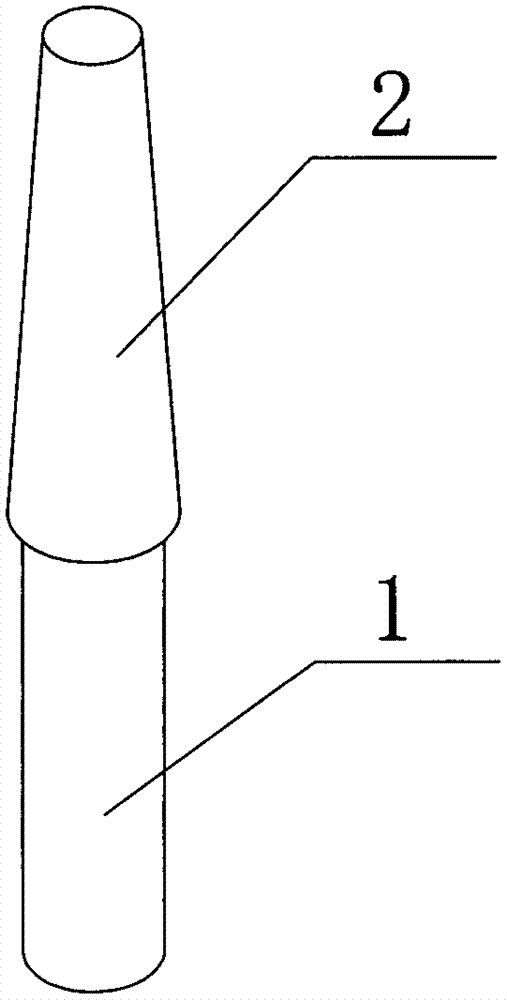

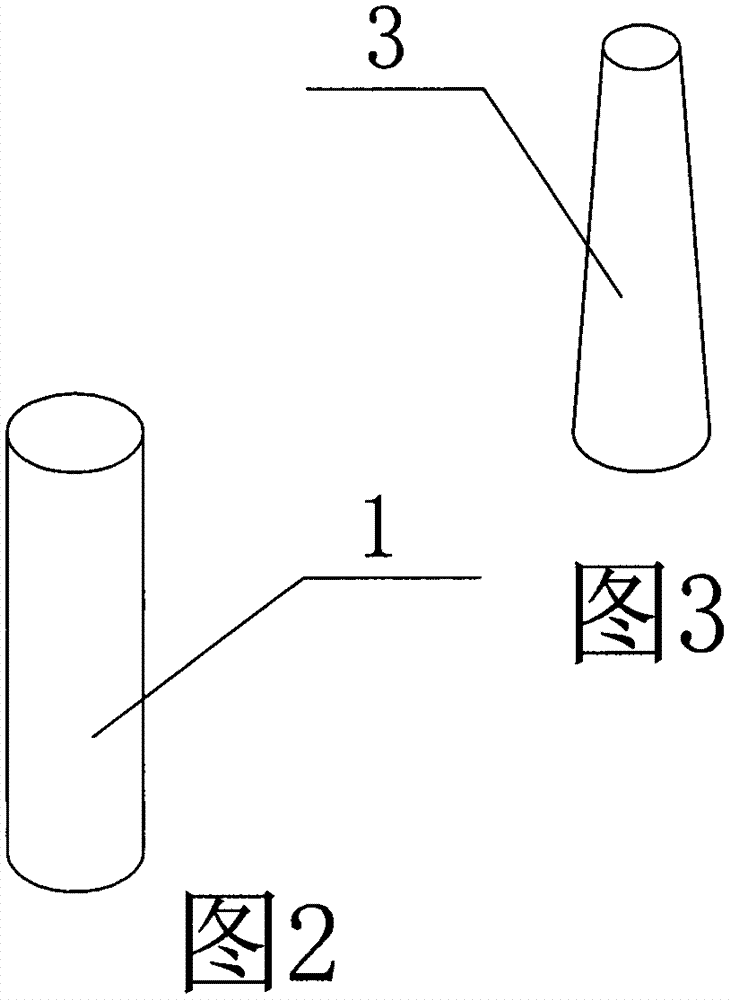

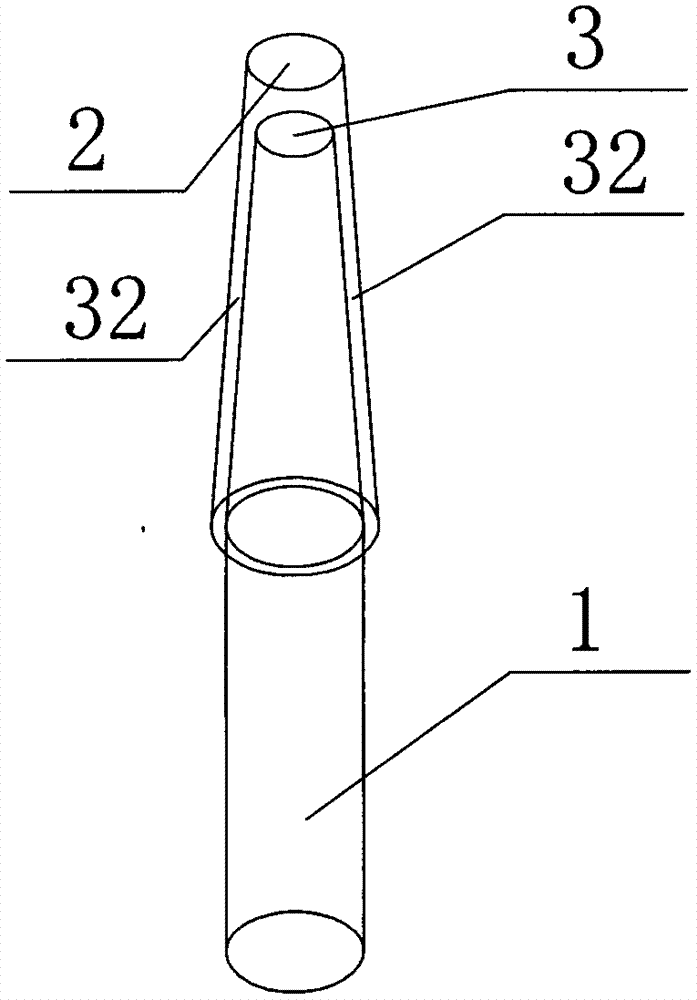

[0022] The composition and the structural relationship of the vacuum tube driven conical casing accelerated exhaust fan of the present invention are:

[0023] The above-mentioned vacuum tube-driven conical casing acceleration exhaust fan is composed of a vacuum tube (1), an inner conical wall (3), and an outer conical wall (2). The outer conical wall (2) and the inner conical wall also form the solar heat collecting sandwich wall. The vacuum tube (1), the outer conical wall (2), and the inner conical wall (3) are coaxially arranged. See figure 1 , Figure 2, Figure 3, Figure 4 .

[0024] The setting of its vacuum tube (1) of vacuum tube driven conical casing of the present invention to accelerate exhaust fan is:

[0025] The above-mentioned vacuum tube drives the conical casing to accelerate the exhaust fan, and the vacuum tube (1) adopts a vertical straight-through vacuum tube. , the upper opening is directly connected to the inlet of the inner conical wall (3), coaxiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com