Novel LNG (Liquefied Natural Gas) cold energy recycling method and device

A new type of cold energy recovery technology, applied in the direction of heat exchanger types, fixed plate conduit components, heat storage equipment, etc., can solve problems such as energy waste, reduce costs, increase flexibility and operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

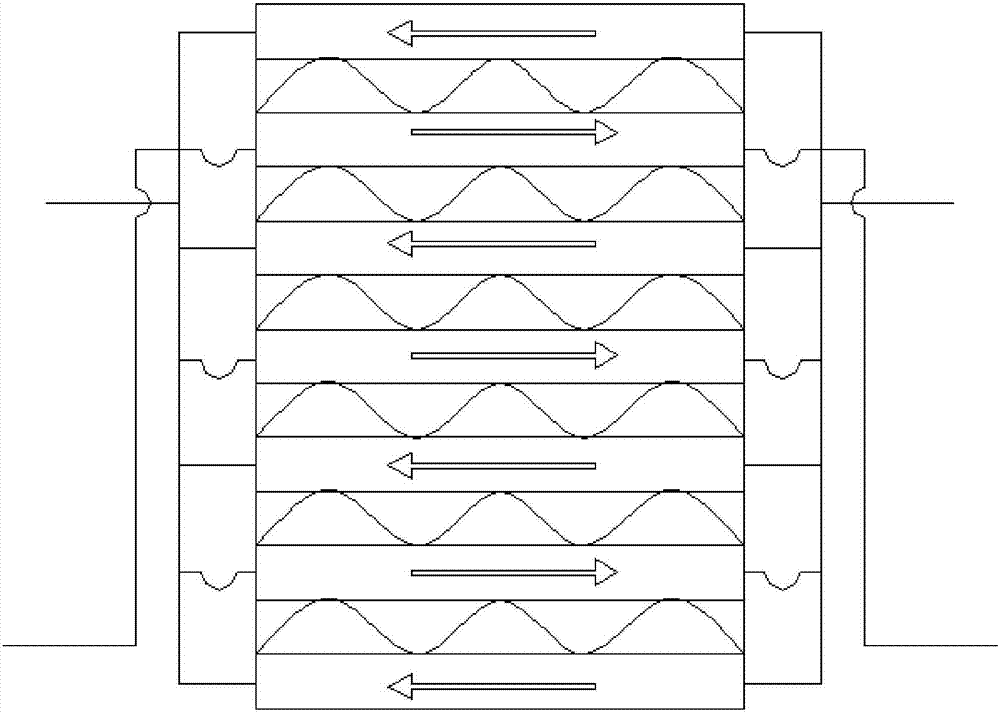

[0014] Such as figure 1 As shown, the liquefied natural gas enters the heat exchanger from the cold storage tank under pressure to exchange heat and then vaporizes. The cold energy is taken away by the countercurrent cold liquid and completely vaporized into gas at the outlet. The cooling liquid and the LNG are separated by the cooling liquid, so that the coldness of the LNG is first stored in the cooling liquid and then taken away by the cooling liquid. In order to ensure complete vaporization, further heat exchange is carried out with the cooling liquid in other layers of heat exchangers, so that the temperature rises again, and then enters the pressure gas storage tank. In this way, the utilization of LNG cold capacity and the storage of vaporized natural gas are realized.

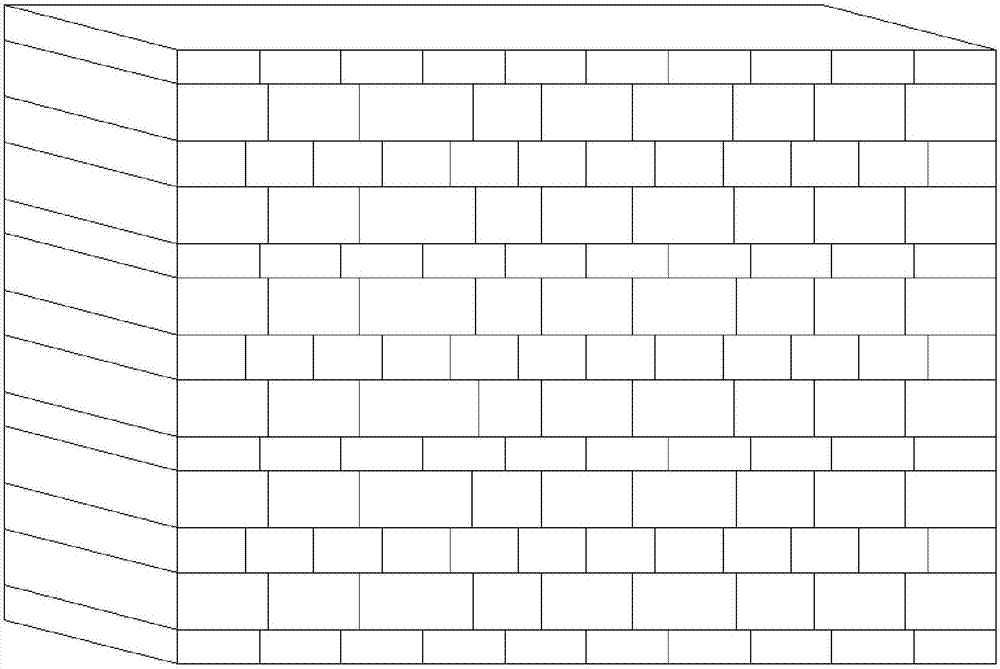

[0015] Such as figure 2 As shown, the heat exchanger in the present invention is composed of a cold taking layer, a cold storage layer and an LNG layer. Each layer is composed of two partitions and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com