Projection equipment optical performance measurement device and method based on motion control

A motion control and projection equipment technology, applied in measurement devices, testing optical performance, optical instrument testing, etc., can solve the problem that the accuracy and standardization of performance measurement of projection equipment are difficult to guarantee, unable to obtain satisfactory detection results, high labor costs and management. Cost and other issues, to achieve the effect of improving measurement accuracy and measurement efficiency, reducing deviation, and achieving accurate automatic positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Embodiments of the present invention will be described in detail below.

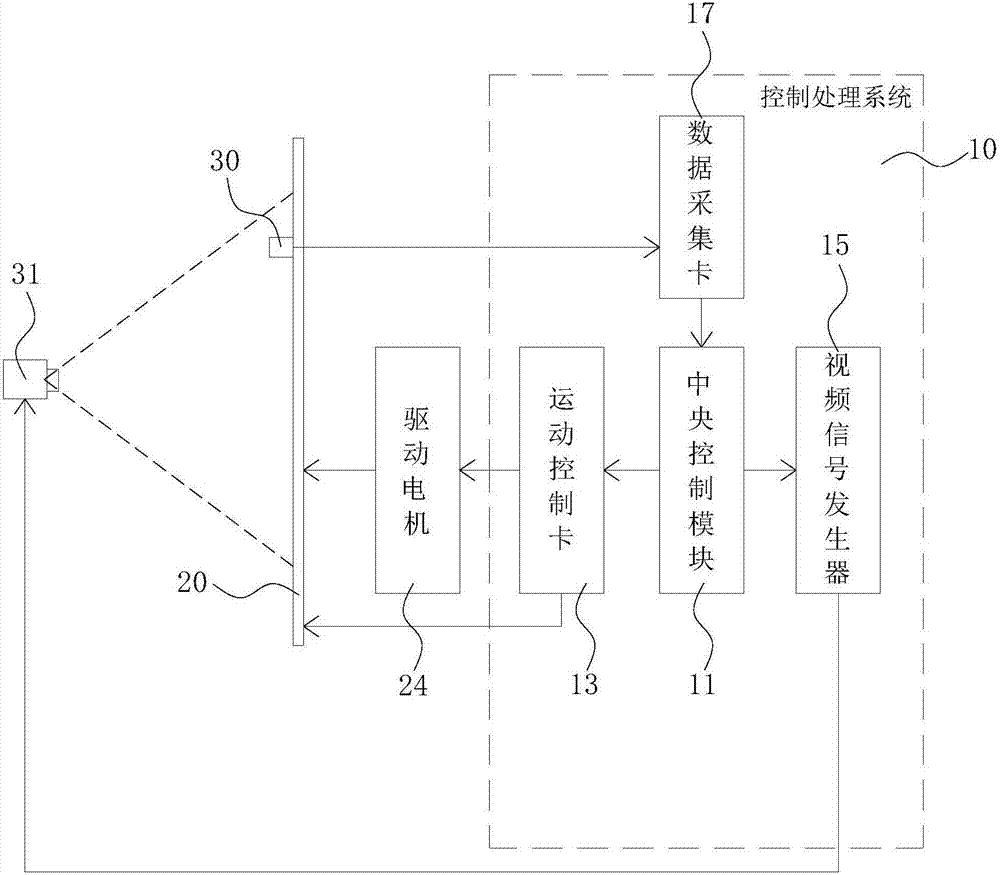

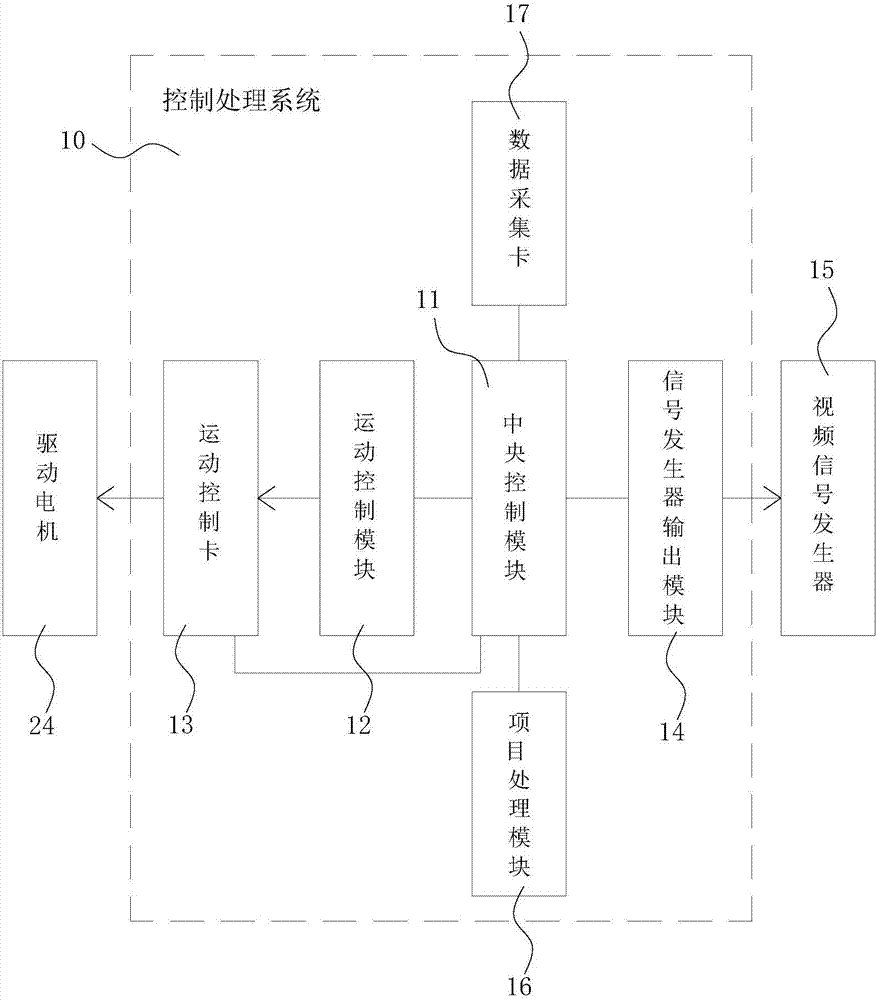

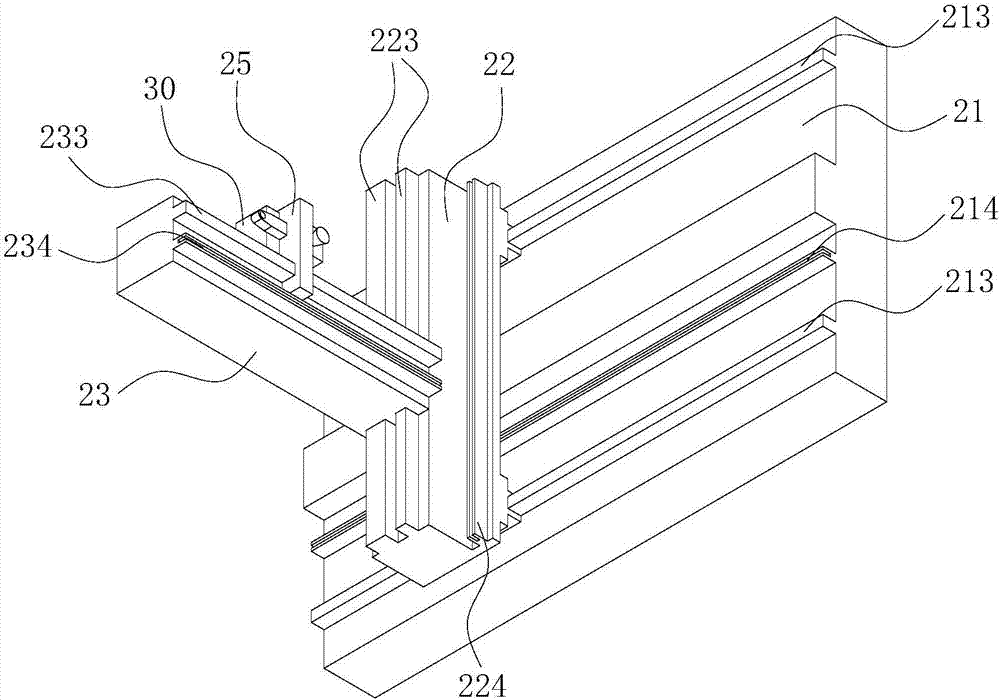

[0072] Such as Figure 1 to Figure 5 As shown, the optical performance measurement device for projection equipment based on motion control includes a control processing system 10, a three-dimensional motion mechanism 20, and a color illuminance meter 30, and the color illuminance meter 30 is mounted on the three-dimensional motion mechanism 20;

[0073] The control processing system 10 is used to send standard test image data to the projection device 31 to be tested; it is used to send motion control instructions to the three-dimensional motion mechanism 20 equipped with the color illuminance meter 30; it is used to collect the measurement data of the color illuminance meter 30, and Process the measurement data of the color illuminance meter 30 to obtain measurement data meeting the comparison conditions;

[0074] The three-dimensional motion mechanism 20 moves according to the motion control ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com