Diagnosis method for through-flow stage efficiency abnormality of steam turbine high-pressure cylinder

A diagnostic method and steam turbine technology, which are applied in gas turbine engine testing, jet engine testing, etc., can solve problems such as abnormal measured flow stage efficiency, abnormal measured flow parameters, and unmentioned problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

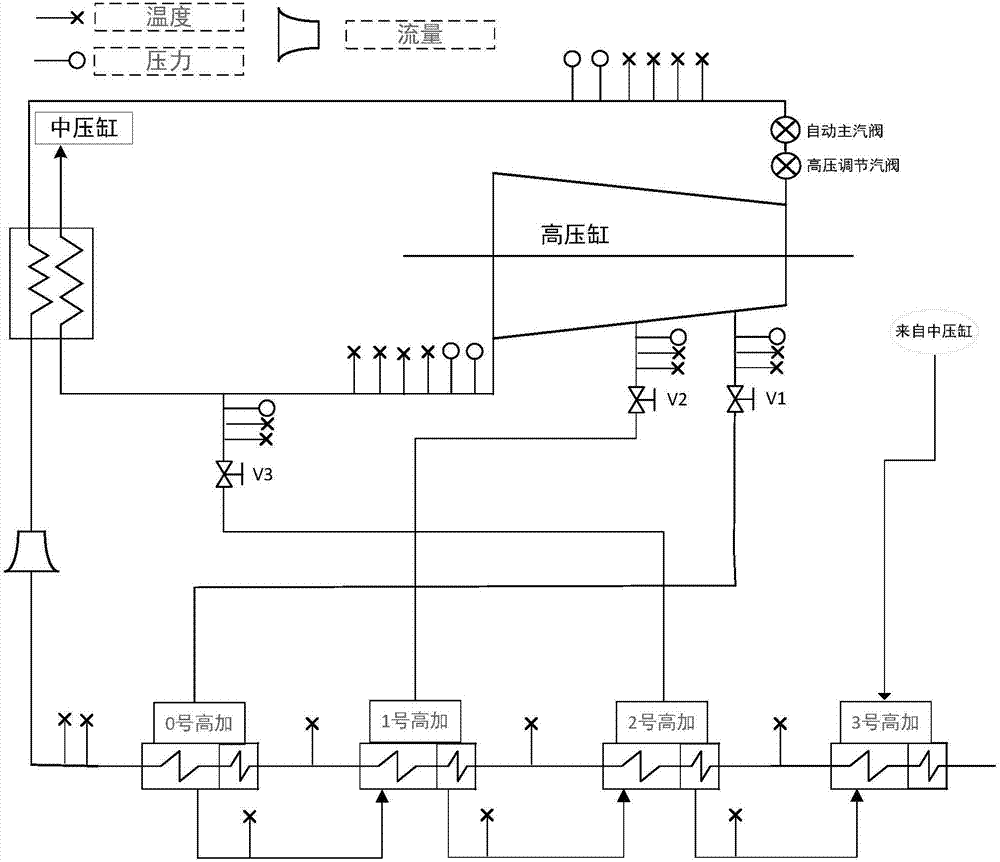

[0038] Such as figure 1 As shown, when the unit has not been put into operation, refer to the ASME PTC6 standard, install temperature and pressure test measuring points on the inlet steam, exhaust steam and each section of the steam extraction pipeline of the high pressure cylinder of the steam turbine, the pressure measuring point is installed upstream, and the pressure measurement adopts The pressure transmitter with an accuracy of 0.075, the temperature measuring point is arranged with double measuring points, the precision grade E-type thermocouple for the test is the primary measuring element, the secondary instrument is measured by the temperature transmitter, and the acquisition system adopts the EIC distributed data acquisition device Combined with the IMP data acquisition board produced by Schlumberger in the UK, the pressure and temperature signals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com