Automobile door fender binding tool

A technology for automobile doors and fenders, applied in the directions of transportation and packaging, vehicle parts, etc., can solve the problems of low demand, high operation requirements and high cost, and achieve the requirements of reducing technical proficiency, reducing labor intensity, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

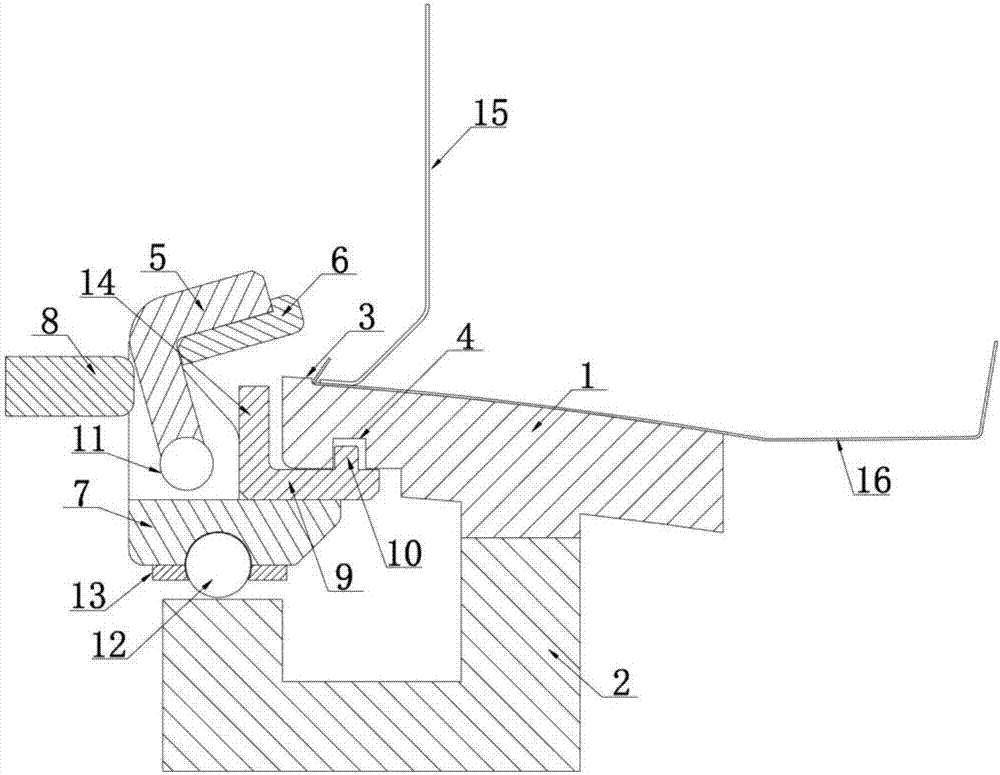

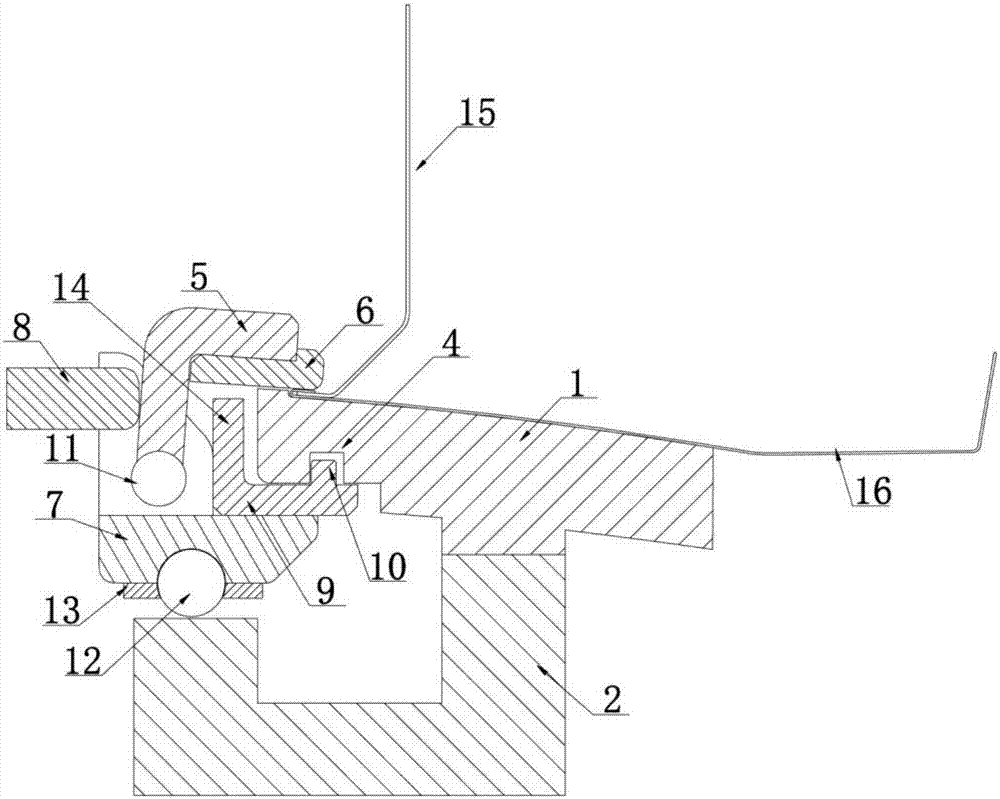

[0023] like figure 1 and figure 2 As shown, an automobile door fender hemming tooling includes a hemming mold 1, a supporting mold 2 and a hydraulic clamp assembly, the top of the hemming mold is provided with a flanging block 3, and the hemming The bottom of the tire is provided with a limit groove 4, and the hydraulic clamp assembly includes a hydraulic jaw plate 5, a panel 6 arranged on the hydraulic jaw plate, a hydraulic clamp base 7, a hydraulic ejector rod 8 and a positioning insert 9, so that The hydraulic jaw plate is installed on the base of the hydraulic jaw through a pin shaft 11, the base of the hydraulic jaw is installed on the supporting mold, the hydraulic ejector rod is arranged behind the hydraulic jaw plate, and the The position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com