Automatic tassel cutting device

A beard cutting and automatic technology, applied in metal processing and other directions, can solve the problems of reducing the quality and sales of agricultural products, difficult to guarantee the quality, time-consuming and laborious, etc., and achieve the effect of good market promotion value, safe and reliable use, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

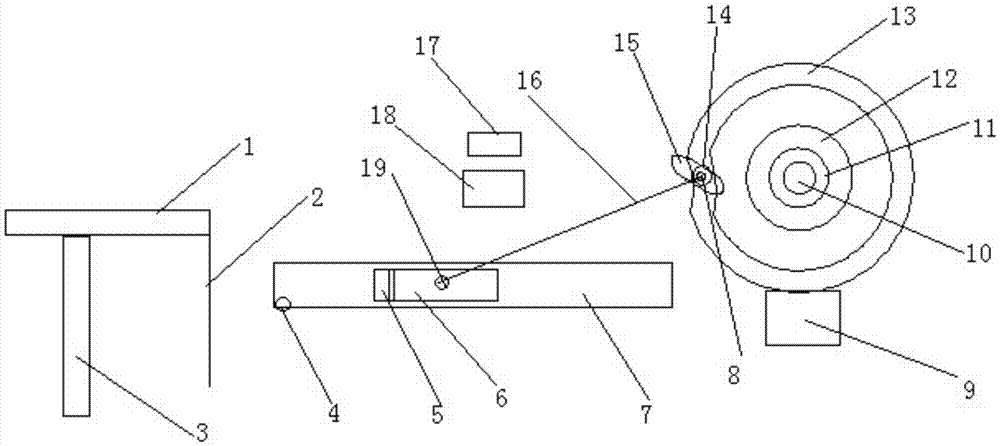

[0027] The patent of the present invention is further described below in conjunction with accompanying drawing:

[0028] refer to figure 1 The embodiment of the patented automatic beard cutting device of the present invention is further described:

[0029] In order to achieve the above object, the patent of the present invention adopts the following technical solutions to achieve:

[0030] The automatic beard cutting device includes: a conveyor belt 1, a cutting board 2, a bracket 3, a sensor 4, a cutter 5, a slider 6, a slide rail 7, a roller shaft 8, a mounting table 9, a motor shaft 10, and a coupling 11 , motor 12, ring track 13, roller 14, mounting block 15, connecting rod 16, switch 17, controller 18, pin shaft 19, conveyor belt 1 is fixed on bracket 3, cutting board 2 is arranged on the side of conveyor belt 1, slides The rail 7 is perpendicular to the surface of the cutting board 2, the slider 6 is arranged inside the slide rail 7, the front end of the slider 6 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com