A kind of synthetic paper printing material and preparation method

A printing material and synthetic paper technology, applied in conductive coatings, temperature recording methods, coatings, etc., can solve the problems of no peeling force of the ink layer, too large difference in properties, and inability to print, and achieve good economic and social benefits. The effect of high temperature adhesion fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

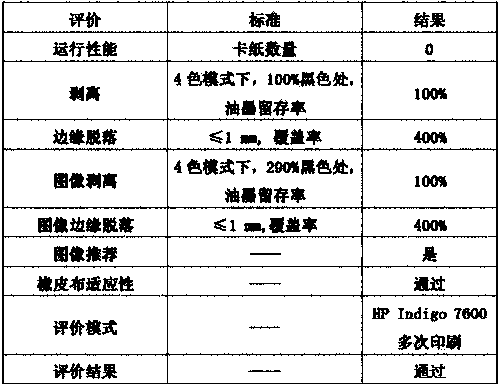

Examples

preparation example Construction

[0043] A method for preparing synthetic paper. The modified aqueous chlorinated polypropylene emulsion includes the following preparation method:

[0044] A). Add chlorinated polypropylene with a chlorine content of 35% to a closed container filled with a mixed solvent of ethyl acetate and methyl ethyl ketone. Under the protection of inert gas, heat to 60°C and stir to make it completely dissolved;

[0045] Ultrasonic emulsification uses the effects of local high temperature, high pressure or strong shock waves and micro jets generated during ultrasonic cavitation to effectively minimize the size of submicron droplets and the uniform and stable dispersion of droplets; ultrasonic emulsification and other emulsification Compared with technology, the droplets can be dispersed finely and narrowly, with high efficiency, good dispersion effect, and increase the stability of the emulsion;

[0046] Ethyl acetate and methyl ethyl ketone are chosen as solvents because their boiling points are ...

Embodiment 1

[0057] Example 1. The coating formulation of the printing coating 1 is composed of the following raw materials in parts by weight: 52 parts of modified aqueous chlorinated polypropylene emulsion; 16 parts of silica sol; 16 parts of water; 6 parts of ethanol; 0.5 parts of leveling agent ; 0.5 parts of defoamer; wherein the diameter of colloidal particles in the silica sol is 20nm;

[0058] The modified water-based chlorinated polypropylene emulsion uses water as the dispersion medium instead of organic solvents. The formula of the modified water-based chlorinated polypropylene emulsion is composed of the following raw materials in parts by weight: 22 parts of ethyl acetate; 32 parts of methyl ethyl ketone; 32 parts of polypropylene; 0.4 parts of benzoyl peroxide; 6 parts of methacrylic acid; 3 parts of butyl acrylate; 3 parts of maleic anhydride; 22 parts of 15% dimethylaminoethanol aqueous solution; 50 parts of deionized water; non-ionic Emulsifier polyoxyethylene cetyl ether 2 p...

Embodiment 2

[0059] Example 2: The coating formulation of the printing coating 1 is composed of the following raw materials in parts by weight: 55 parts of modified aqueous chlorinated polypropylene emulsion; 17 parts of silica sol; 18 parts of water; 8 parts of ethanol; 0.5 parts of leveling agent ; 0.5 parts of defoamer; wherein the diameter of colloidal particles in the silica sol is 20nm;

[0060] The modified water-based chlorinated polypropylene emulsion uses water instead of organic solvents as the dispersion medium. The formula of the modified water-based chlorinated polypropylene emulsion is composed of the following raw materials in parts by weight: 25 parts of ethyl acetate; 35 parts of methyl ethyl ketone; 35 parts of polypropylene; 0.5 parts of benzoyl peroxide; 6 parts of methacrylic acid; 3 parts of butyl acrylate; 3 parts of maleic anhydride; 25 parts of 15% dimethylaminoethanol aqueous solution; 50 parts of deionized water; non-ionic Emulsifier polyoxyethylene cetyl ether 2 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com