A thermosetting resin composition, a prepreg containing the same, a metal foil-clad laminate, and a printed circuit board

A resin composition and thermosetting technology, applied in the field of laminate materials, can solve the problems of not obvious improvement of heat resistance, light aging resistance and water absorption, poor preservation, low viscosity stability, etc., and achieve drilling processability. Excellent, low water absorption, low cost effect

Active Publication Date: 2019-01-22

GUANGDONG SHENGYI SCI TECH

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the use of epoxy resin with this structure, the problems of low viscosity stability and poor preservation have been successfully solved, but the improvement of heat resistance, light aging resistance and water absorption is not obvious

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Login to View More

Abstract

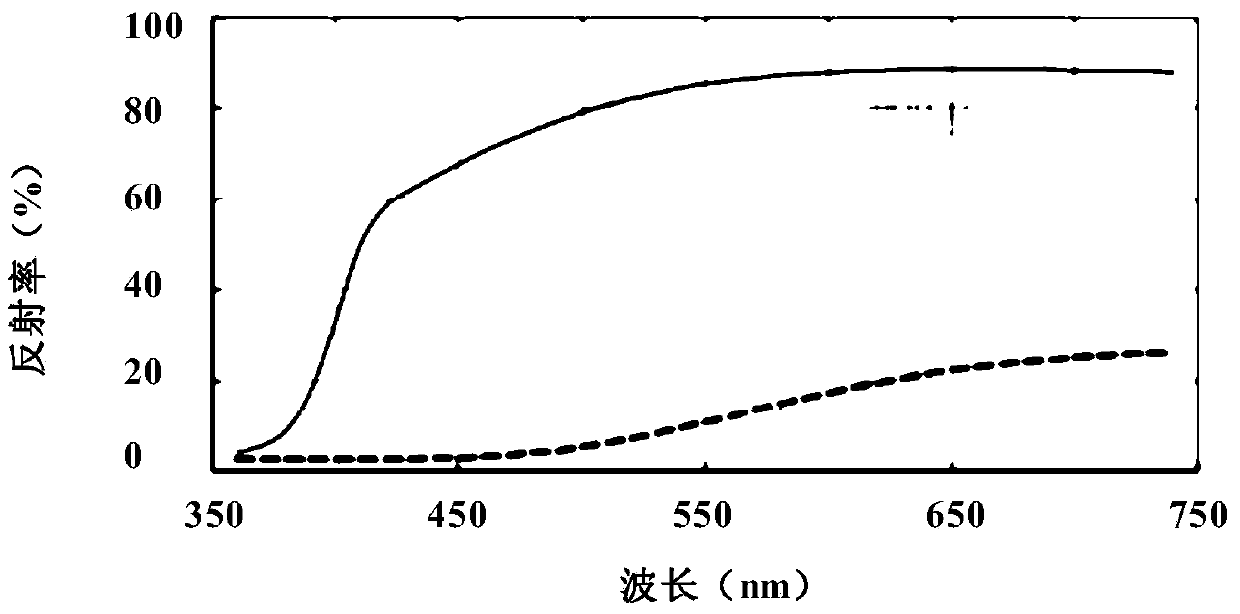

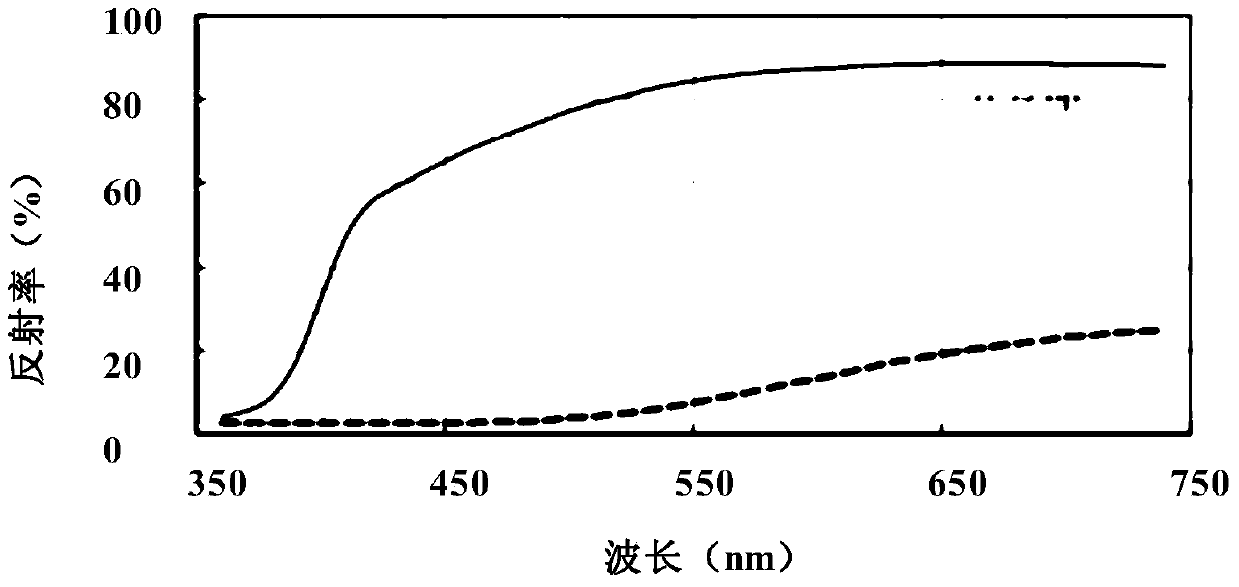

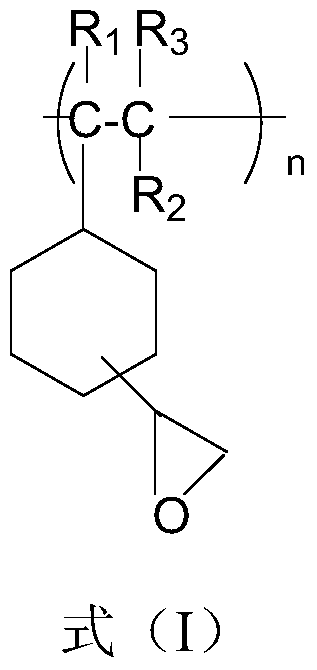

The invention provides a thermosetting resin composition, a prepreg containing the same, a metal foil-coated laminate, and a printed circuit board. The thermosetting resin composition comprises alicyclic epoxy resin with a structure as shown in a formula I. Through usage of the alicyclic epoxy resin with a specific structure, the prepared resin composition has excellent resistance to yellowing caused by heat, resistance to ageing caused by light and excellent drilling processability; and a laminate, the metal foil-coated laminate and the printed circuit board prepared from the composition have excellent heat resistance, excellent resistance to ageing caused by light and a water absorption rate of 0.32% or below. According to the invention, the problems of proneness to yellowing and ageing under heat and proneness to yellowing and ageing under illumination of traditional printed circuit boards are overcome; and a preparation process for the thermosetting resin composition is simple and feasible and is low in cost.

Description

technical field The invention belongs to the field of laminate materials, and relates to a thermosetting resin composition, a prepreg containing it, a metal foil-clad laminate and a printed circuit board. Background technique In recent years, the structure of LEDs has also changed, from a structure with pins to a chip structure (Chip-LED), making surface mount LEDs a reality and further promoting the miniaturization of electronic products. Surface-mounted LEDs are made by directly mounting the light-emitting elements on the electrodes of the PCB and encapsulating them with resin. Under long-term light conditions, due to aging and discoloration, the light reflectivity will drop significantly, which will affect the working quality and service life of electronic products. For chip LEDs, traditional FR-4 copper-clad laminates have been difficult to meet their use requirements. Japanese Patent No. 4634856 discloses the use of alicyclic epoxy and its composition with the follow...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L63/00C08G59/24C08G59/32C08G59/50C08K3/22C09J163/00C08J5/24B32B27/38B32B15/20B32B15/092H05K1/02

CPCB32B15/092B32B15/20B32B27/38C08G59/24C08G59/32C08G59/50C08J5/24C08K3/22C08L63/00C08L2201/08C08L2203/20C09J163/00H05K1/02

Inventor 黄增彪成浩冠雷爱华

Owner GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com