Shell mosaic floor and production method for same

A production method and technology of shells, applied in the field of shell inlaid flooring and its production, can solve the problems of complicated process and poor decoration effect, and achieve the effects of simple process, high production efficiency and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

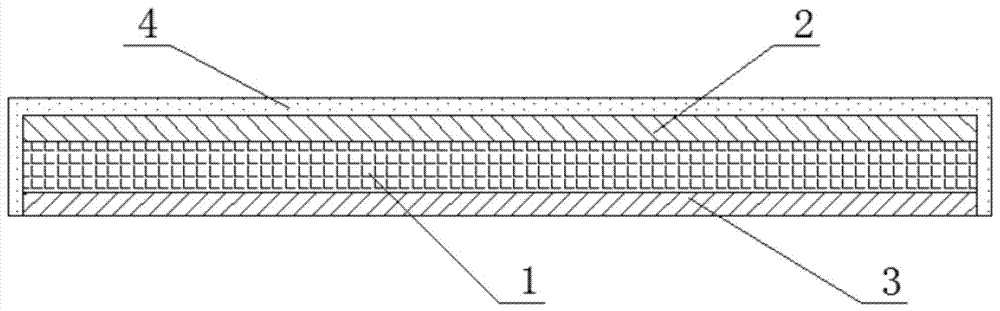

[0015] A shell inlaid floor in this embodiment, which includes a wooden board blank 1, a shell layer 2, a balance layer 3 and an acrylic resin layer 4, and the shell layer 2 is arranged on the wooden board blank 1 and bonded to the wooden board blank 1 The balance layer 3 is arranged on the lower surface of the plank blank 1, and the acrylic resin layer 4 is arranged on the top of the shell layer 2 and around the edges of the floor.

[0016] A method for producing a shell inlaid floor, wherein: it consists of the following steps:

[0017] 1) Blank preparation and pretreatment: cut the wood into the desired shape, plan and sand the surface, then dry the wood with a vacuum dryer, control the moisture content to 4%, and make a wood blank;

[0018] 2) Shell layer preparation: design patterns according to the needs of the product, crush, cut, polish and polish the shells according to the designed pattern, and then glue them together with resin glue to make a shell layer with a thic...

Embodiment 2

[0023] A shell inlaid floor in this embodiment, which includes a wooden board blank 1, a shell layer 2, a balance layer 3 and an acrylic resin layer 4, and the shell layer 2 is arranged on the wooden board blank 1 and bonded to the wooden board blank 1 The balance layer 3 is arranged on the lower surface of the plank blank 1, and the acrylic resin layer 4 is arranged on the top of the shell layer 2 and around the edges of the floor.

[0024] A method for producing a shell inlaid floor, wherein: it consists of the following steps:

[0025] 1) Blank preparation and pretreatment: Cut the wood into the desired shape, plan and sand the surface, then dry the wood with a vacuum dryer, control the moisture content to 6%, and make a wood blank;

[0026] 2) Shell layer preparation: design patterns according to the needs of the product, crush, cut, polish and polish the shells according to the designed pattern, and then glue them together with resin glue to make a shell layer with a thic...

Embodiment 3

[0031] A shell inlaid floor in this embodiment, which includes a wooden board blank 1, a shell layer 2, a balance layer 3 and an acrylic resin layer 4, and the shell layer 2 is arranged on the wooden board blank 1 and bonded to the wooden board blank 1 The balance layer 3 is arranged on the lower surface of the plank blank 1, and the acrylic resin layer 4 is arranged on the top of the shell layer 2 and around the edges of the floor.

[0032] A method for producing a shell inlaid floor, wherein: it consists of the following steps:

[0033] 1) Blank preparation and pretreatment: cut the wood into the desired shape, plan and sand the surface, then dry the wood with a vacuum dryer, control the moisture content to 8%, and make a wood blank;

[0034] 2) Preparation of the shell layer: design patterns according to the needs of the product, crush, cut, polish and polish the shells according to the designed pattern, and then glue them together with resin glue to make a shell layer with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com