Quick coupling and working method thereof

A fast, male plug technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of impact water seepage, plugging and unplugging with less leakage, etc., to achieve the effect of ensuring fast circulation, easy mating, and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

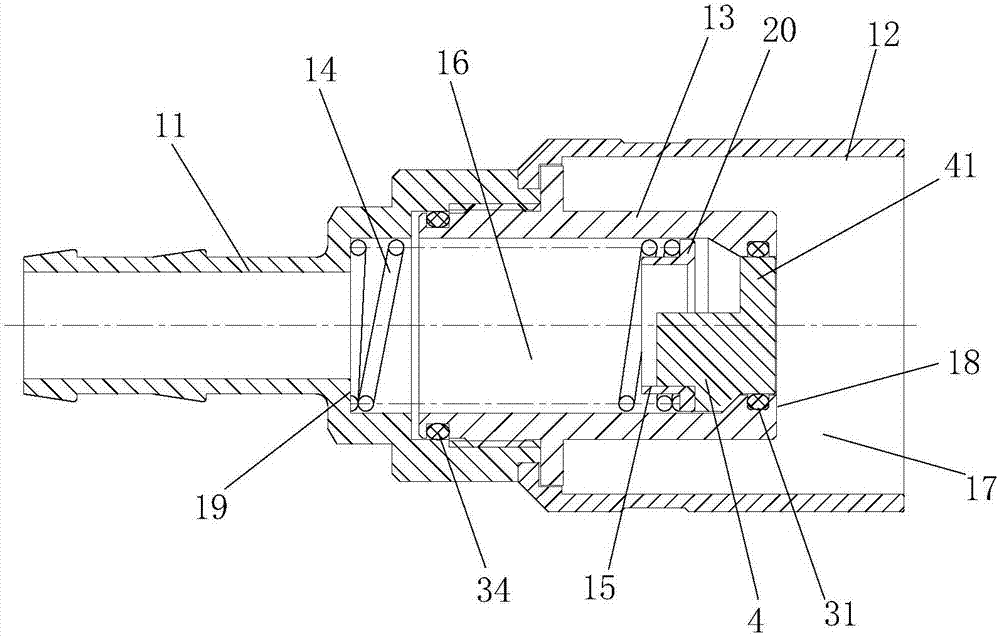

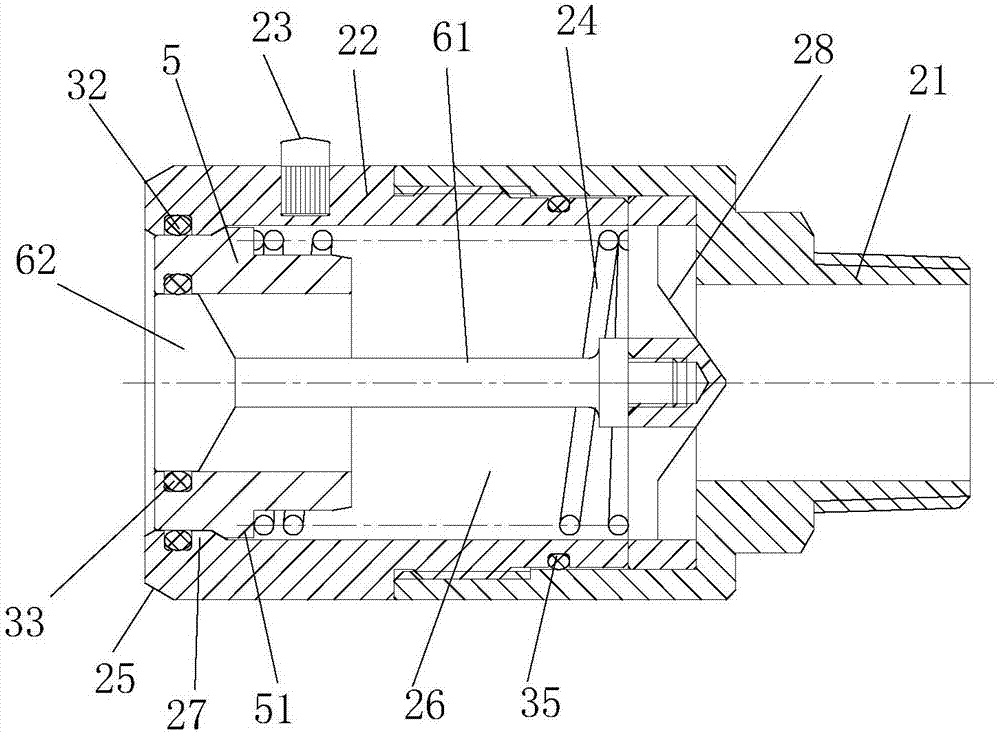

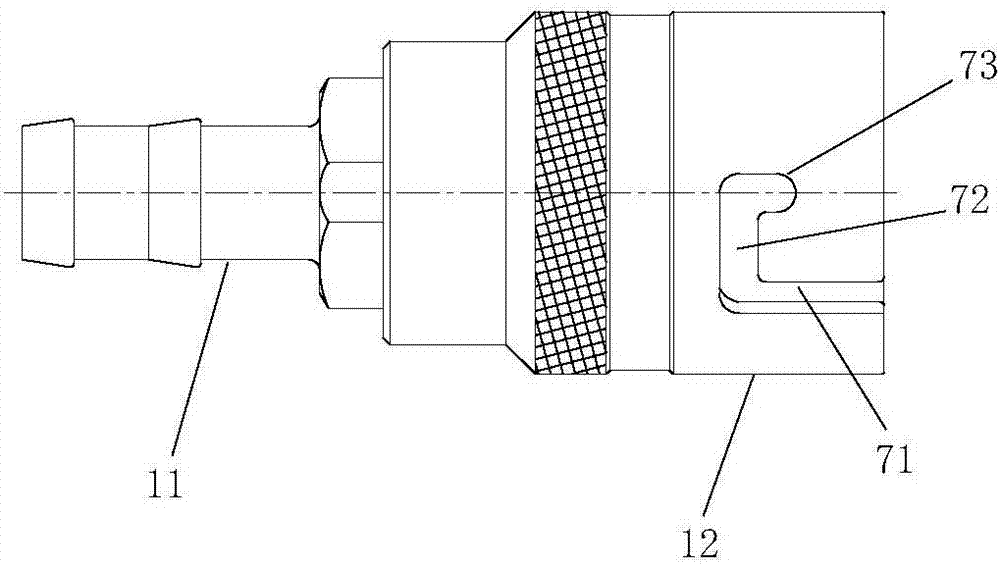

[0028] Embodiment 1 The quick connector of this embodiment includes a plug-fit male plug and a female plug (for the convenience of discussion, when referring to the front end, the components in the male plug refer to the end near the connection between the male plug and the female plug, and the opposite end is the tail end; when referring to the tail end, the parts in the female plug refer to the end near the connection between the male plug and the female plug, and the opposite end is the front end); figure 1 As shown, the male plug includes a first sleeve 11 of the male plug, a second sleeve 12 of the male plug, and a third sleeve 13 of the male plug. In the tail end of the third sleeve 13 of the male plug, the tail end of the third sleeve 13 of the male plug is sealed and sleeved in the front end of the first sleeve 11 of the male plug, and a fourth annular groove is arranged on the outer wall of the tail end of the third sleeve 13 of the male plug. A fourth O-ring 34 is ar...

Embodiment 2

[0037] The working method of quick coupling as described in embodiment 1, comprises the steps:

[0038] A. When the male plug is in the initial state, the first spring 14 supports the first valve core 4 to reach the front end of the third sleeve 13 of the male plug, and the annular side wall of the first sealing disc 41 and the third sleeve 13 of the male plug An annular sealing part 18 is sealed and fitted through the first O-ring 31, so that the male plug is in a closed state; when the female plug is in the initial state, the second spring 24 supports the second valve core 5 to reach the end of the second sleeve 22 of the female plug end, the outer wall of the second spool 5 seals with the second annular sealing portion 27 of the second sleeve 22 of the female plug through the second O-ring 32 , and the inner wall of the second spool 5 passes through the third O-ring 33 It is sealingly matched with the annular side wall of the second sealing disc 62, so that the female plug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com