Dynamic calibration test bench of force measurement wheel pair

A force measuring wheelset and dynamic calibration technology, applied in the field of rail transit, can solve the problems of low work efficiency, inaccurate analysis of final results, complex structure, etc., and achieve the effect of small installation space, automatic calibration, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

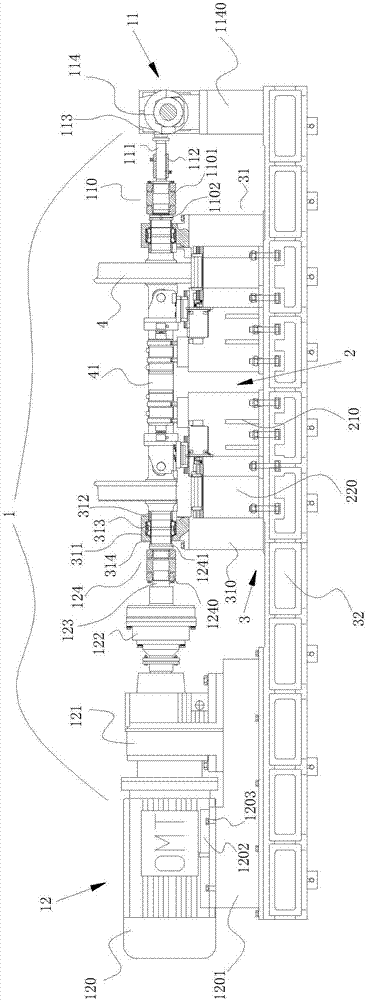

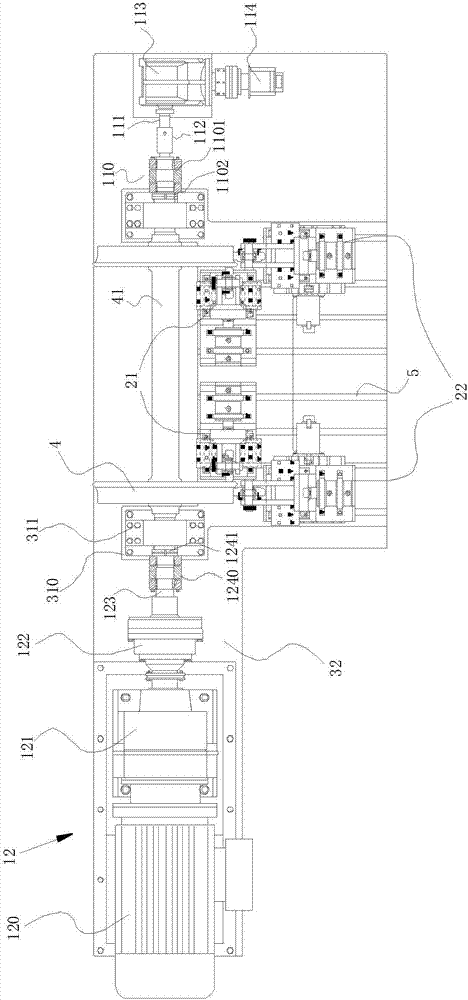

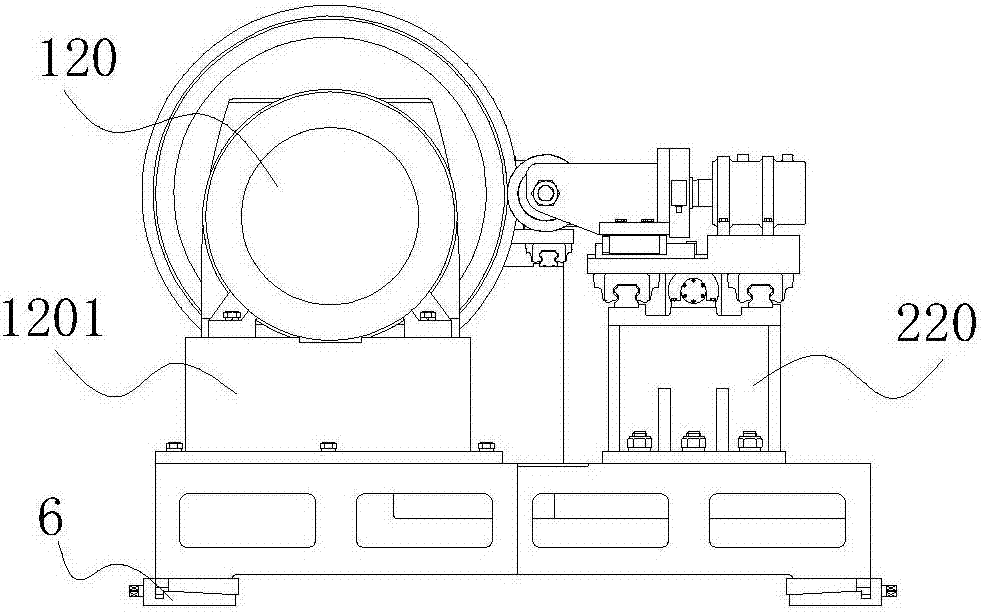

[0021] Such as figure 1 As shown, the dynamic calibration test bench of the force-measuring wheel set of the present invention includes a loading system 2 for loading the force-measuring wheel set 4, a support system 3 for supporting the force-measuring wheel set 4 and the loading system 2, and also includes a force-measuring wheel set The power system 1 in which the force wheel pair 4 is switched between the static calibration state and the dynamic calibration state. In the static calibration state, the power system 1 can make the force measuring wheel pair 4 rotate to any angle for loading. In the dynamic calibration state, the power The system 1 can make the force measuring wheel 4 rotate continuously at a low speed for loading. The support system 3 includes a support frame 31 supporting the two axial ends of the force-measuring wheel pair 4 and a base 32 arranged at the bottom of the support frame 31 for the installation of the loading system 2 , and the support frame 31 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com