Low-frequency large-displacement horizontal movement vibration bench

A technology of horizontal motion and vibration table, applied in vibration testing, testing of machine/structural components, measuring devices, etc., it can solve the problems of high vibration frequency and small amplitude, and achieve stable working state, simple structure, and convenient assembly and replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The working principle of the present invention is as follows:

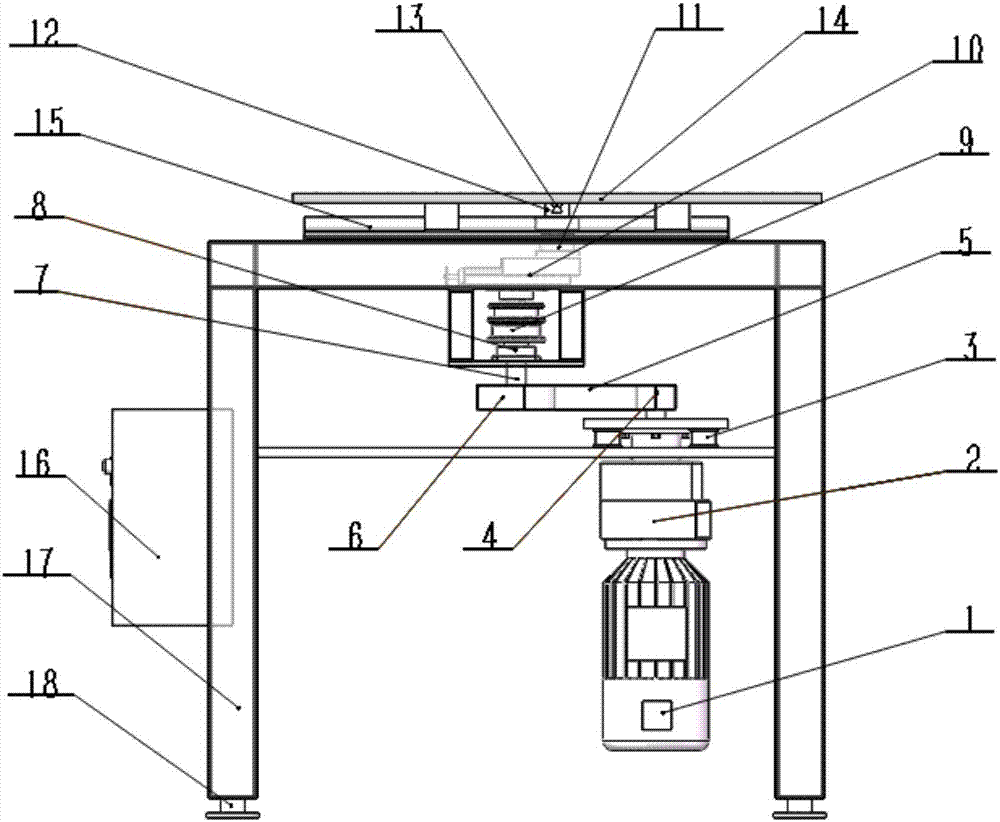

[0020] See attached figure 1 , the low-frequency large-displacement horizontal vibrating table disclosed in the present invention includes a motor 1 (three-phase AC variable-frequency speed-regulating motor, YVP112M-4-200), a gearbox 2 (TL modular combination gear reducer, RF07-4KW -4P-23.37-M2), damping device 3, small pulley 4, synchronous belt 5, large pulley 6, transmission spindle 7, spindle bearing 8, electromagnetic clutch and brake (dry single-plate electromagnetic clutch, TJ- A-1.5) 9. Eccentric adjustment device 10, bearing seat hole 11, slider 12, table guide rail 13, table top 14, base guide rail 15, frequency conversion box 16 (KC inverter, KC510-055G375P3), base 17, level The adjustment member 18 is supported.

[0021] The invention relates to a low-frequency large-displacement horizontal vibrating table, including a power and control device, a braking device, a transmission mechanism, a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com