Circulating water injection mechanism for gas cylinder multi-station automatic pressure-tight test device

A technology of a pressure test device and a water injection mechanism, which is used in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problem of difficult to meet the automatic operation of automatic test production lines, low test operation efficiency, and labor intensity of workers. Large and other problems, to achieve the effect of good sealing, improved service life and high work efficiency

Inactive Publication Date: 2017-07-04

JIANGSU ZHONGHONG MACHINERY MFG

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above-mentioned connection and sealing method of the hydraulic test head requires the operator to manually screw in. The whole operation process is cumbersome, the labor intensity of the workers is high, and the efficiency of the test operation is low, which is difficult to meet the automatic operation requirements of the automated test production line.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0034] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

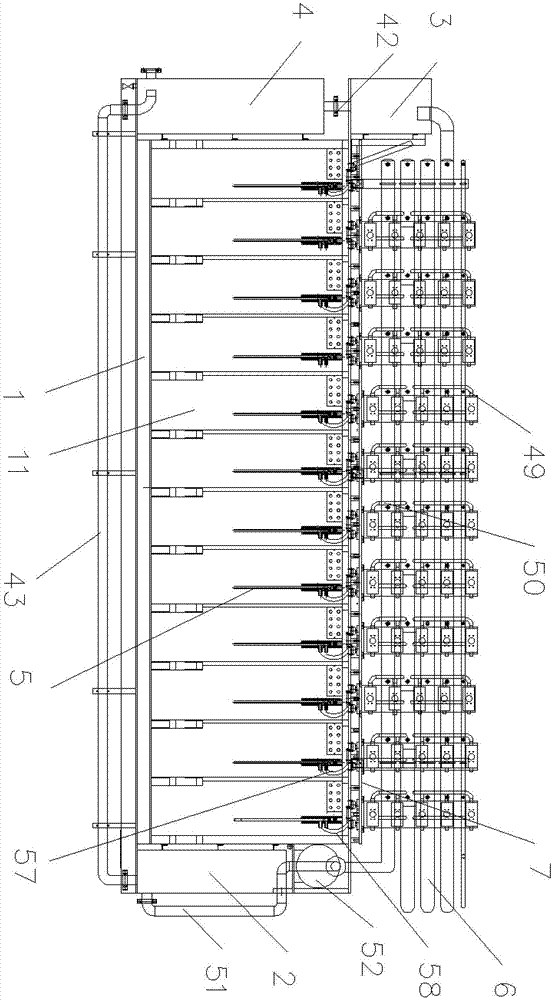

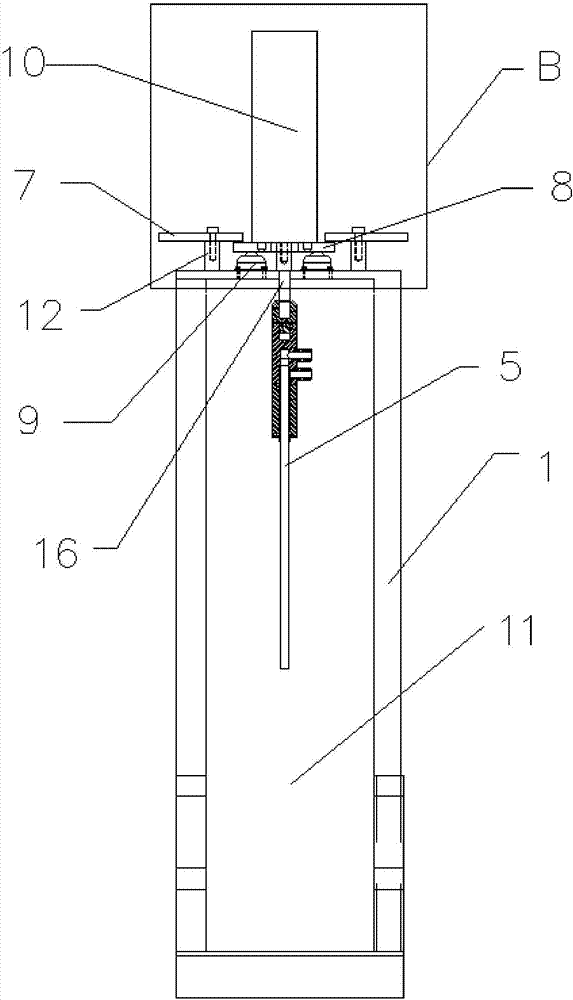

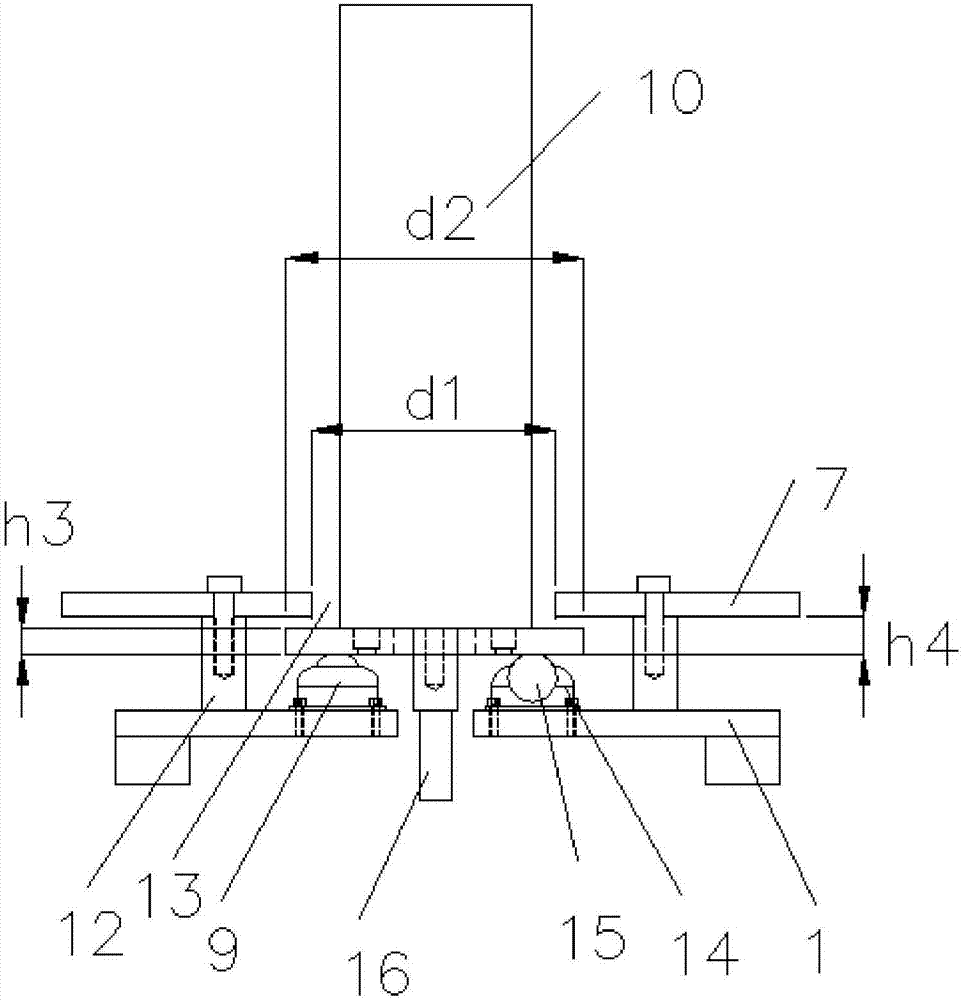

The invention relates to a circulating water injection mechanism for a gas cylinder multi-station automatic pressure-tight test device. The circulating water injection mechanism comprises a water injection mechanism frame, a water injection tank, a water return tank, a precipitation water tank, a water injection device, a pipe system, a first fixed platform, a second fixed platform, a support mechanism group and a second cylinder. The circulating water injection mechanism has strong universality. According to the gas cylinder position, a position of a water injection pork can be manually adjusted. The circulating water injection mechanism has high work efficiency, low labor intensity, a long service life of the equipment, can recycle water and realizes energy saving and environmental protection.

Description

technical field [0001] The invention relates to a water injection mechanism, in particular to a circulating water injection mechanism used in a gas cylinder multi-station automatic pressure test device. Background technique [0002] As a loading tool for various gases, gas cylinders are widely used in people's daily life and industrial production. There are a huge number of gas cylinders, which are often moved and reloaded repeatedly, and the use environment is often relatively harsh. Once an explosion occurs, it will bring serious losses to people's lives and property, and have a huge impact on social security. In order to strengthen the safety supervision of gas cylinders, ensure the safe use of gas cylinders, and protect personal and property safety, each gas cylinder must be checked one by one and regularly tested. Combining automation and computer technology, automatic gas cylinder hydraulic testing technology, including pressure test, external test method test and int...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/12

CPCG01N3/12G01N2203/0019G01N2203/0048

Inventor 向忠潘云俊

Owner JIANGSU ZHONGHONG MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com