An explosion-proof junction box made of a new material with high safety performance

An explosion-proof junction box and safety performance technology, applied in the field of junction boxes, can solve the problems of unsafe use and low sealing performance, and achieve the effects of simple structure, good sealing performance, and improved anti-corrosion and wear-resistant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

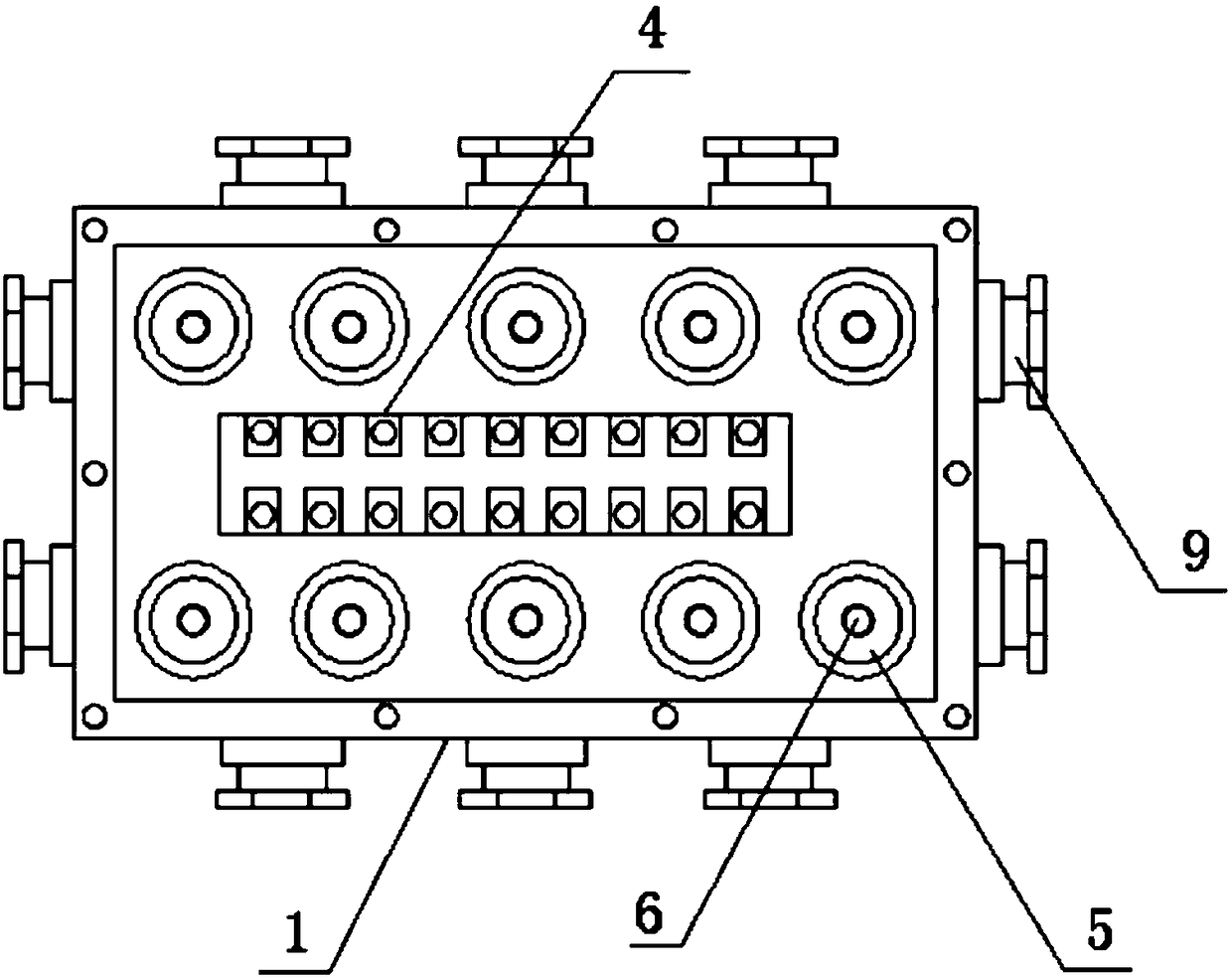

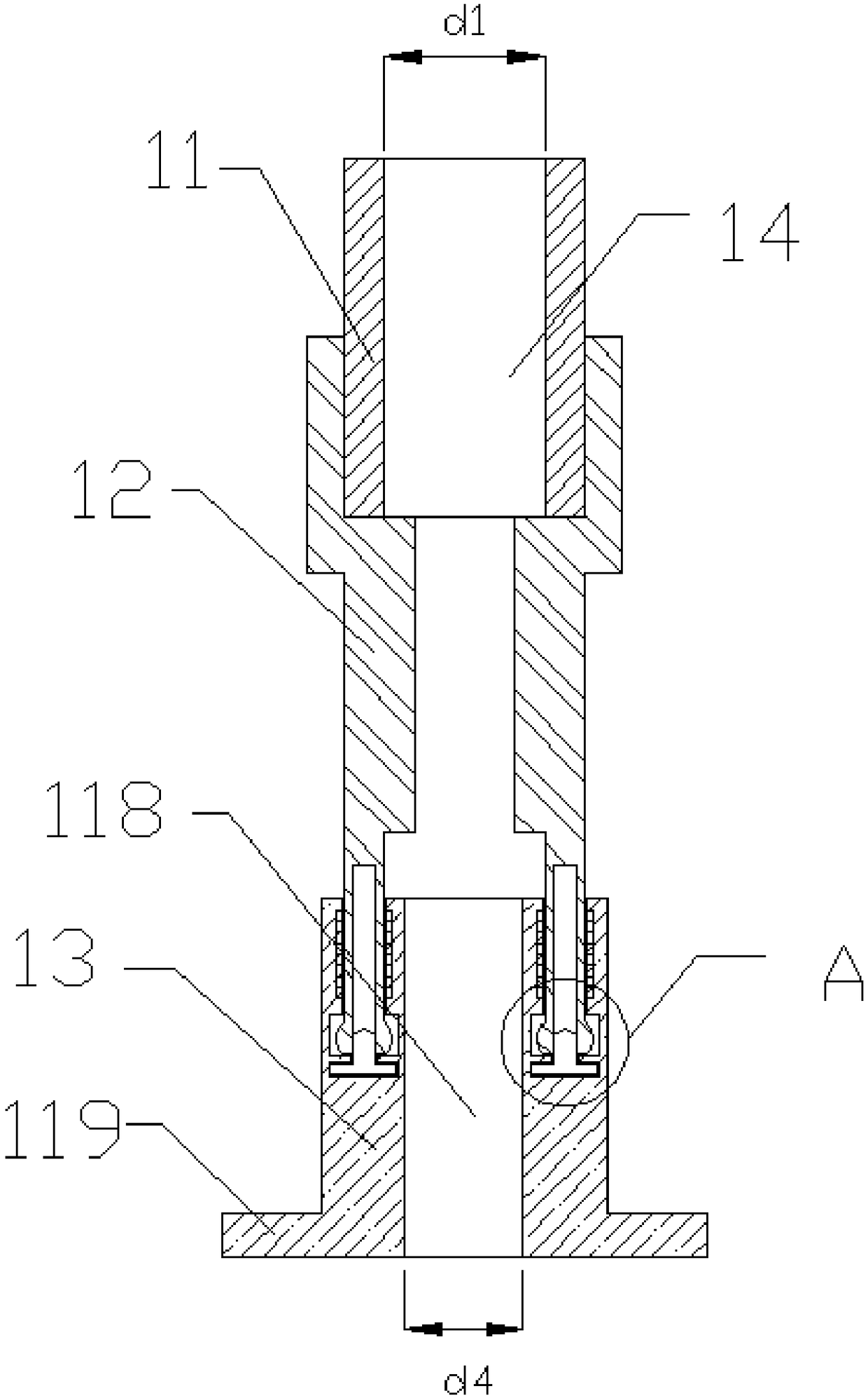

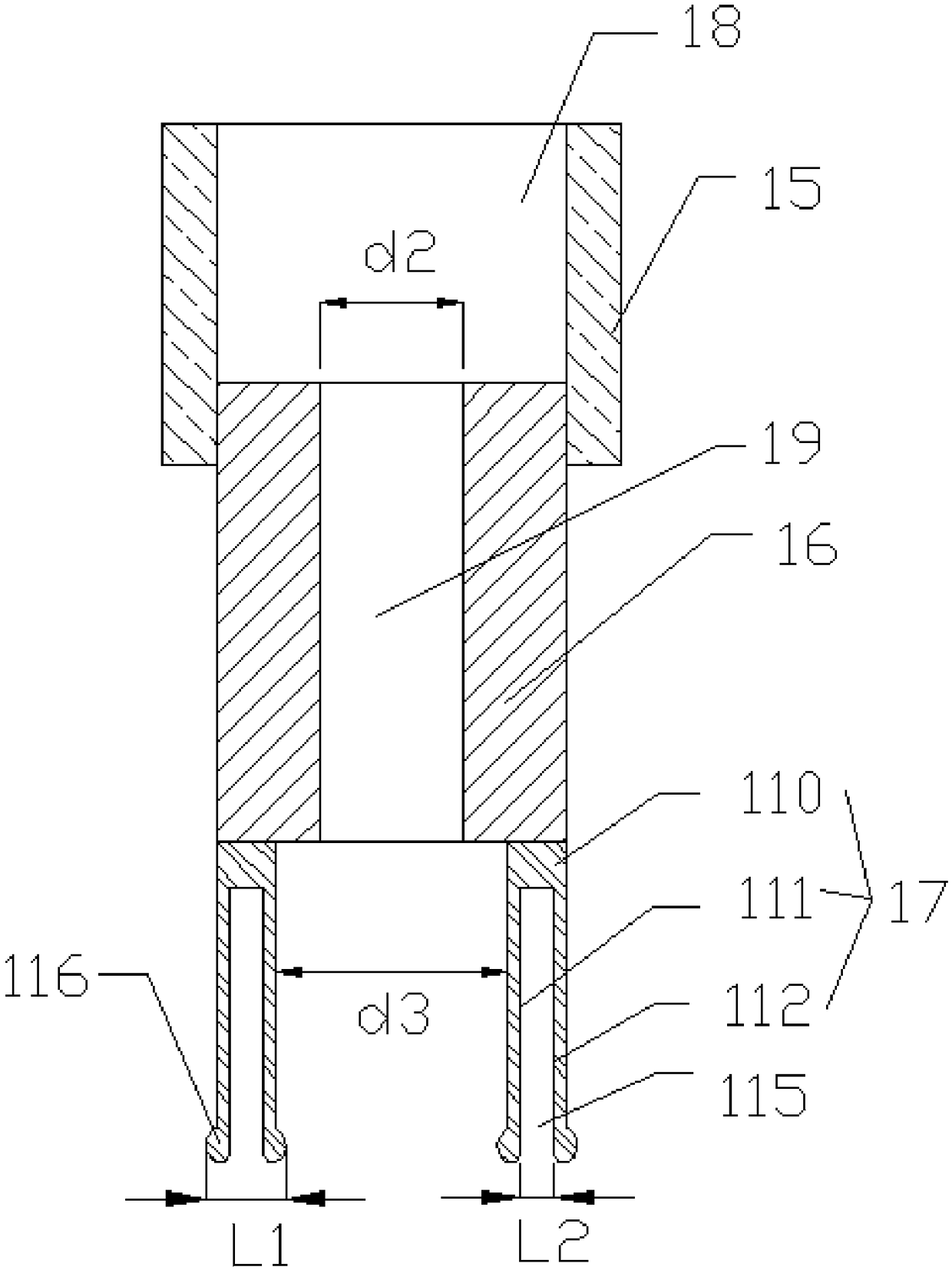

[0032] As shown in the figure, an explosion-proof junction box of new materials with high safety performance is composed of a box body 1, a box cover and a threading opening. The inside of the box body is provided with a terminal row 4, and the four walls of the box body are provided with more than one Each threading port inside the box body is provided with a winding shaft 5, and the said winding shaft is connected with the screw port at the bottom of the box by the screw I6, and each threading port is provided with a cable sealing joint 9, and the cable The sealing joint includes a locking mechanism 11, a threading mechanism 12, and a fixing mechanism 13. The locking mechanism and the threading mechanism are locked and fixed through thread cooperation, and the threading structure is inserted into the fixing mechanism, and the fixing mechanism is fixed on the threading port;

[0033] The locking mechanism is a cylindrical structure, the locking mechanism is provided with a fir...

Embodiment 2

[0041] The explosion-proof junction box of a new material with high safety performance described in Embodiment 1 is different in that:

[0042] A protective layer is coated on the casing, and the composition of the protective layer is as follows in parts by weight:

[0043] 35 parts of epoxy resin, 0.5 parts of high alumina ceramic particles, 3 parts of methyl isobutyl ketone, 2 parts of polyacrylamide, 1 part of sodium pyrophosphate, 2 parts of diphenyl ethylene glycol, 0.1 part of acetone, polyoxypropylene glycerin 8 parts of ether, 4 parts of isophthalic acid, 15 parts of chlorinated paraffin, 1 part of titanium dioxide, 20 parts of n-butanol;

[0044] The preparation method of the protective layer is as follows: add the above-mentioned components into a ball mill, and after ball milling and stirring for 4 hours, transfer to a reaction kettle, stir for 1 hour at a temperature of 85° C., make it evenly mixed, and lower the temperature to 45° C. ℃, and maintained at this tem...

Embodiment 3

[0046] The explosion-proof junction box of a new material with high safety performance described in Embodiment 1 is different in that:

[0047] A protective layer is coated on the casing, and the composition of the protective layer is as follows in parts by weight:

[0048] 48 parts of epoxy resin, 4 parts of high alumina ceramic particles, 9 parts of methyl isobutyl ketone, 8 parts of polyacrylamide, 3 parts of sodium pyrophosphate, 4 parts of diphenyl ethylene glycol, 2 parts of acetone, polyoxypropylene glycerin 16 parts of ether, 10 parts of isophthalic acid, 22 parts of chlorinated paraffin, 4 parts of titanium dioxide, 35 parts of n-butanol;

[0049] The preparation method of the protective layer is as follows: add the above-mentioned components into a ball mill, and after ball milling and stirring for 8 hours, transfer it to a reaction kettle, stir for 2 hours at a temperature of 120°C, make it evenly mixed, and lower the temperature to 55°C. ℃, and maintained at this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com